Replacing instinct with insights

Industrial technology is driving new standards for manufacturing efficiency—yet many organizations struggle to adopt new technology due to lack of resources needed to deploy and scale.

Manufacturers face daily pressures and challenges, making it difficult to allocate the time or resources needed to implement new technology in their plants. Partnering with an outsourced technology provider like ATS for maintenance in Industry 4.0 eases the burden on manufacturers. Reliability experts can help leverage technology to their advantage, using data-driven insights to predict impending work and prevent unplanned downtime.

Be proactive not reactive

Improve overall operational efficiency

Increase safety with remote monitoring

Increase efficiency with connected devices

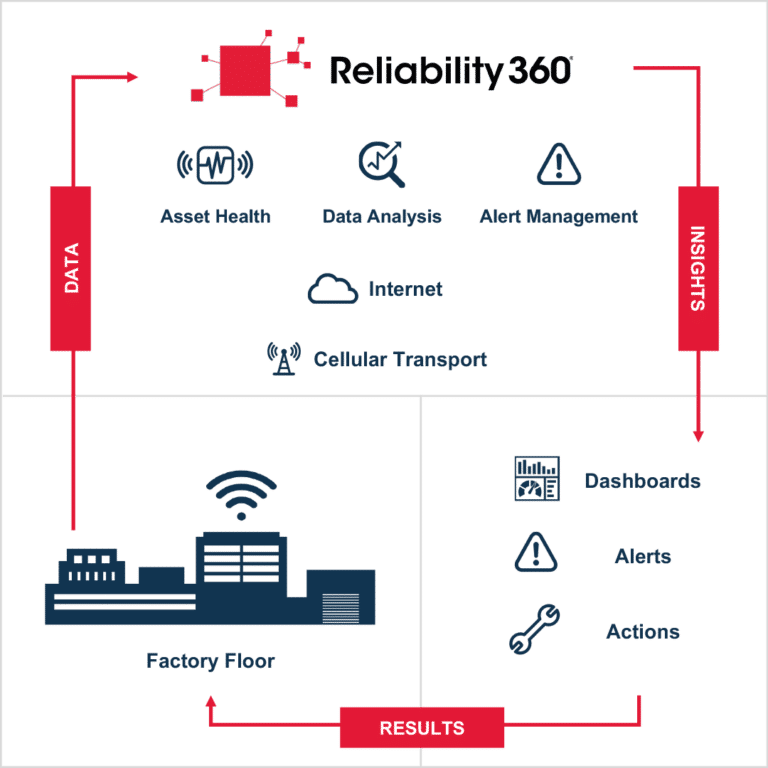

What is Reliability 360®?

Our 360-degree industrial maintenance, reliability and technical expertise provides leading manufacturers with end-to-end maintenance solutions enabled by industrial technology. The best-in-class practices we’ve perfected over the years doing maintenance at thousands of factories translates into unmatched value for our customers.

Through our unique end-to-end IIoT solution of people, processes, parts and connected technologies, we are able to make factories run better and smarter. Drive uptime with machine health monitoring, ROI guaranteed.

Harness cutting-edge technology to improve equipment reliability

ATS combines cutting-edge sensor technology with decades of maintenance and reliability expertise, enabling your on-site maintenance team to detect and resolve equipment failures before they occur. Our holistic machine health monitoring approach and guaranteed 3x ROI, builds the foundation for long-lasting, strategic partnerships with our customers.

-

Over 4 in 5 manufacturers

continue partnership with ATS for long-term, reliable machine health monitoring.

-

20+ sensors available

With a growing portfolio built to enhance reliability and meet evolving customer needs.

-

3X ROI

Confidently invest in new technology, ROI guaranteed.

-

Real results, real impact

See how our solution helped a leading manufacturer avoid $7M in costs.

Find out more!

Eliminate common MRO challenges

ATS brings together data from your business units and ERP, EAM, or P2P systems and turns that data into actionable insights. We can help you achieve network-wide material visibility, reduce search and order costs, improve service levels and strengthen alignment between operations and procurement.

- Harmonize MRO data across plants, systems and teams

- Optimize existing inventory levels while reducing risk

- Gain visibility to MRO materials across your networks

- Capture team expertise & knowledge

- Proactively address tail spend reduction opportunities

- Onboard quickly and unlock value within 60 days

“Because of the new-age technologies ATS utilizes, our plant runs smoother and safer.”– Leading Aerospace Manufacturer

ATS technology FAQs

How is ATS using Industry 4.0?

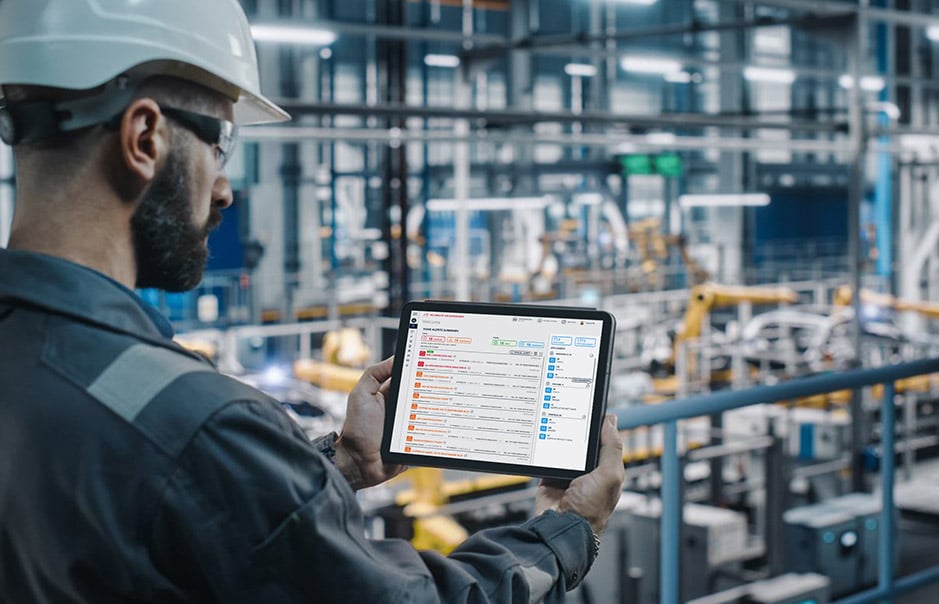

The rapid development of new industrial technologies has made it essential for us to provide data-driven approaches and strategies to our customers. Our remote monitoring and analysis expertise through the latest sensor technologies allows us to drive a more proactive approach to maintenance.

What types of technology does ATS provide?

We offer many predictive Industry 4.0 maintenance services to fit your plant floor needs including wireless sensors. By incorporating sensor technology, proprietary dashboards and analytics within our machine health monitoring system, we track key metrics on critical assets and provide actionable insights for on-site maintenance teams.

We also provide AI-powered MRO technology, which brings together data from your business units and ERP, EAM, or P2P systems and turns that data into actionable insights. Through this technology and our MRO expertise, we can help you achieve network-wide material visibility, reduce search and order costs, improve service levels and strengthen alignment between operations and procurement.

What metrics can you measure with the ATS Machine Health Monitoring System?

Our sensors collect machine data related to vibration, temperature, current, pressure and humidity based on the critical assets you want to monitor.

R360® Machine Health Monitoring

Monitor the real-time condition of your equipment through sensor technology to prevent unplanned downtime and achieve measurable ROI.

R360® Technology Center

Improve machine reliability and uptime with the monitoring and analytical support of our R360® Technology Center team of experts.

Explore resources

Learn about industrial maintenance best practices and gain insights from ATS thought leaders and industry experts.