Preventing downtime with condition monitoring

When a golf cart manufacturer sought to safeguard their production equipment, they turned to ATS for the data analytics and reliability expertise to support their manufacturing process.

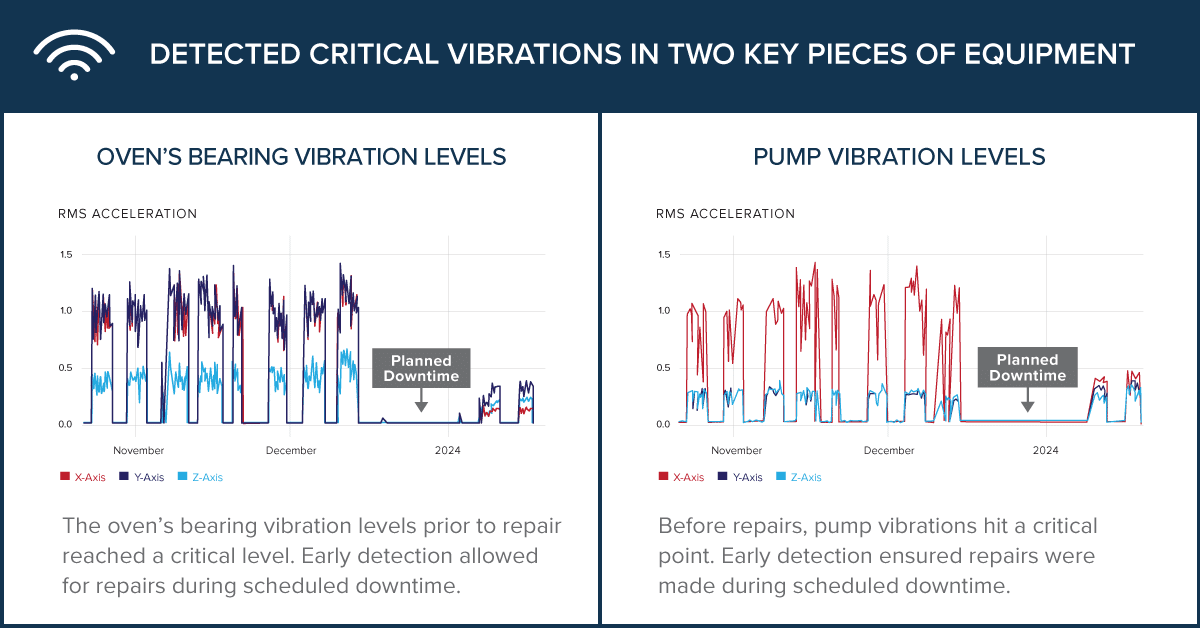

Sensing potential failures

ATS Reliability 360® team remotely detected high spikes in vibration on a dry-off oven’s bearing and a pump at the manufacturer’s plant. Early detection allowed for quick planning and action to be taken across both assets.

Proactive repairs

The on-site maintenance team was alerted and replaced the oven fan’s bearing and shaft. Additionally, the pump and its motor were replaced. Through ATS sourcing and parts expertise, parts were ordered in advance. All repairs were made during a period of scheduled downtime, avoiding disruption in production. After repairs, vibration levels returned to normal on both assets.

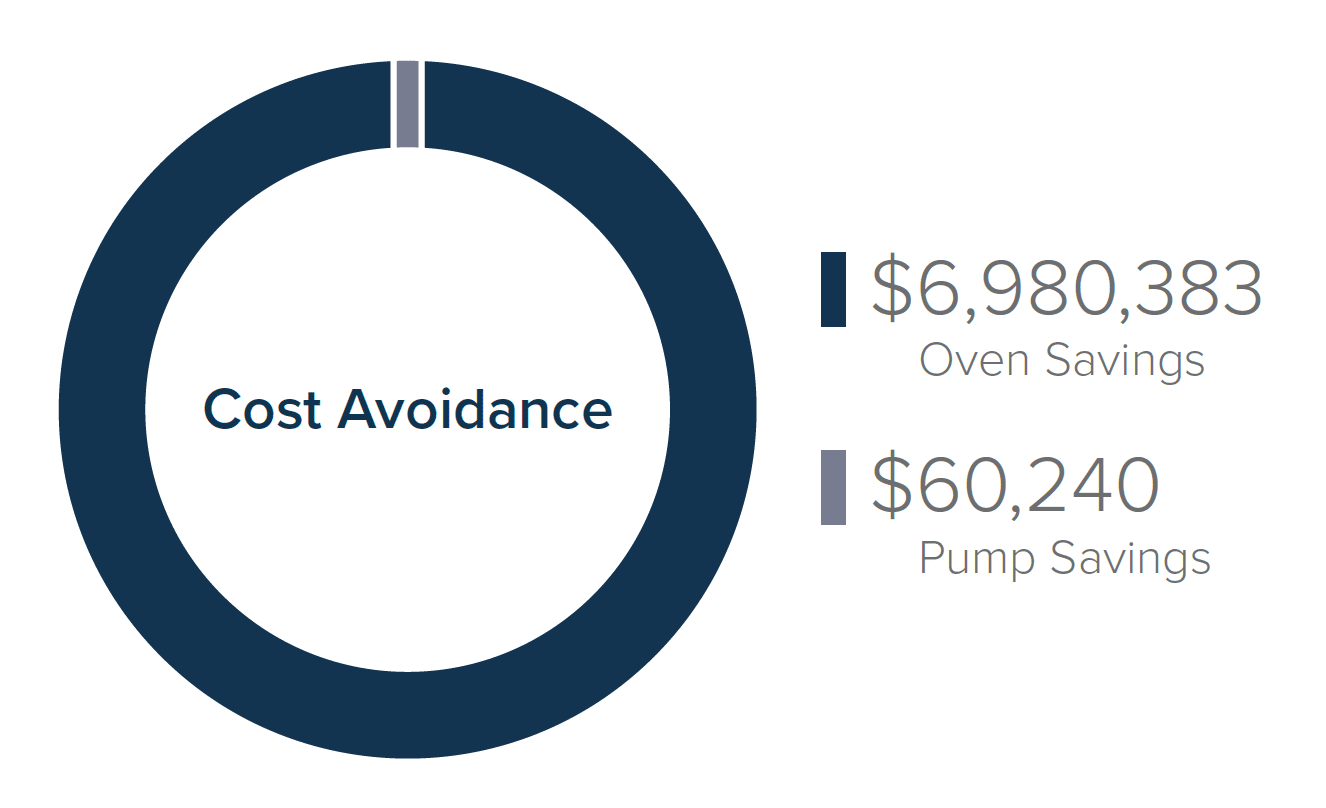

Results

The combination of remote condition monitoring and on-site expertise led to significant savings, surpassing $7 million in avoided production costs, while ensuring over 240 hours of potential downtime were successfully prevented, achieving zero production loss.

Discover the power of Reliability 360®

Not all condition monitoring solutions are created equal. Learn more about the value Reliability 360® Machine Health Monitoring can bring to your operations below. Ready to get started? Contact us today.

What's included? | Reliability 360® Machine Health Monitoring | Alternatives |

Custom Installation & Plant Assessment | ||

Real-Time Continuous Equipment Monitoring | ||

Onboarding Program & Knowledge Base | ||

Analytics Dashboards & KPIs | ||

Customizable CMMS/ERP Integration | ||

US-Made Hardware & US Managed | ||

20+ Sensor Types | ||

Optional Maintenance & Parts Services | ||

Guaranteed ROI | ||