Our solutions drive performance

Partnering with ATS provides a strategic advantage for industrial maintenance operations by delivering tailored solutions that directly address the root causes of underperformance. Our experienced technicians and turnkey support services help standardize workflows, implement predictive technologies, and optimize machine uptime. These efforts not only enhance OEE but also drive measurable ROI and improve product quality, all while aligning with modern manufacturing best practices.

Increase uptime and asset reliability

Keep equipment running longer with proactive, precision-driven maintenance.

Improve plant performance and OEE

Optimize every shift with data-backed strategies to boost efficiency.

Stop missing production deadlines

Avoid delays with streamlined workflows and real-time visibility.

Gain control over unnecessary costs

Cut waste and control expenses with smarter resource allocation.

We understand your operational challenges

We understand the operational challenges our customers face—missed production goals and plant underperformance are often symptoms of deeper issues such as difficulty in finding, training, and retaining skilled technicians, reliance on reactive maintenance, inefficient processes, and outdated technology. That is why we design our solutions to meet the specific needs of each facility, ensuring that our customers can overcome these obstacles and achieve sustainable operational excellence.

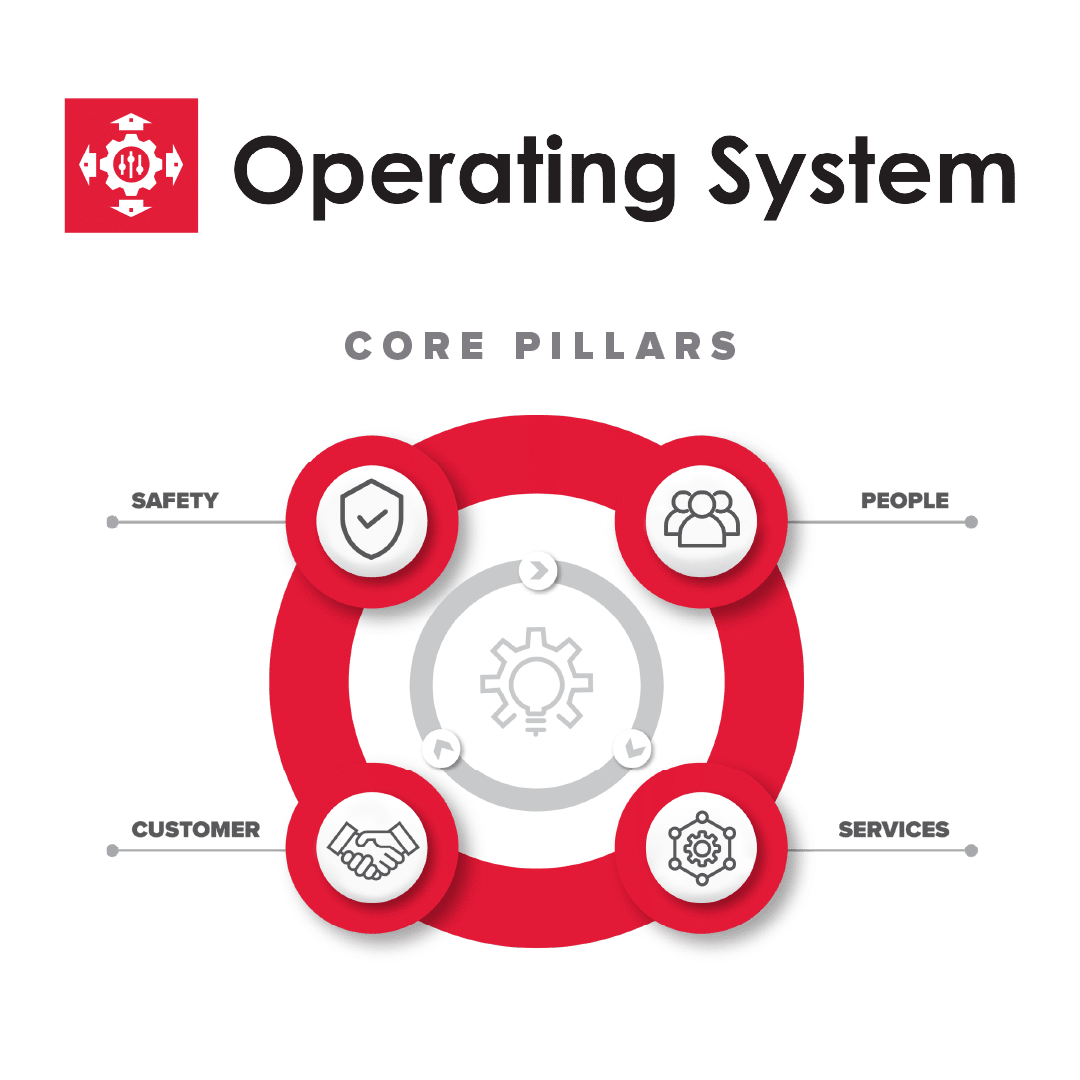

At the heart of our approach are the core pillars of our operating system: Safety, People, Customer, and Services. These pillars guide every aspect of our work and are fundamental to how we deliver consistent, high-quality results. They form the foundation of our success and ensure that we not only meet but exceed the expectations of our partners.

Solving operational challenges

We know a solution for industrial operations professionals is only as good as the results it delivers. That’s why our comprehensive manufacturing operations solution provides the metrics that matter most to you: uptime and productivity.

“Since partnering with ATS, there have been significant improvements in reducing downtime and aligning with our operational needs.”

Benefit from proven processes

Operational excellence is at the core of everything you do. Our best-in-class work execution management comes from over three decades of consistent, quality service delivery to hundreds of manufacturers.

We provide manufacturing operations leadership with assistance that drives better performance and results. This is accomplished through a wide range of processes and methodologies, including:

- Improving OEE: Our comprehensive maintenance services boost OEE by reducing downtime and increasing productivity.

- Production schedule optimization: Our experts review your schedules to provide recommendations to streamline them for peak output.

- Reducing maintenance backlogs: Partnering with us ensures proactive service that prevents delays and keeps equipment running smoothly.

Safety excellence starts with ATS

At ATS, we prioritize safety excellence. We work with maintenance teams to implement processes and procedures, reducing incidents and improving employee well-being.

-

World-class safety

Our Beyond Zero safety culture prioritizes compliance and employee well-being

-

Low incident rates

ATS has a 50% lower recordable incident rate than industry average

-

Exceed OSHA standards

ATS has an industry-leading OSHA incident rate and regulatory compliance

Driving operational efficiency

With expertise across a broad range of industrial operations services that drive plant performance forward, ATS can help you evolve from reactive to proactive maintenance with a program that will deliver the improved asset reliability you need.

Maintenance excellence in action

We pride ourselves in the quality service and measurable results we deliver to our customers. Check out our customer successes in the resources section.