Building maintenance excellence together

Manufacturers of building products and supplies strive to avoid the equipment downtime that negatively impacts quality, delivery and production costs. The bottom line depends on equipment availability, so keeping equipment running optimally with avoided unplanned downtime is key. Our skilled technicians can provide the construction materials manufacturing maintenance services building product manufacturers need to improve uptime, increase productivity and see measurable results.

Our expertise in equipment used in building products manufacturing allows us to help your factory overcome operational challenges while increasing uptime and optimizing productivity. Our knowledge of your equipment includes, but is not limited to:

Conveyors

Motion Control

Pumps

Mixers

Robotics

Packaging & Labeling

Pulpers/Hydrapulpers

Kiln/Kettle

“Our diagnostic tools, which have allowed us to identify and correct many issues before extended downtime is incurred, are key building blocks for best-in-class maintenance.”– Leading Building Products Manufacturer

Reliability excellence and beyond

Our skilled workforce, established processes and innovative, data-driven technologies combine to help you meet your unique business needs. Whether you lack skilled workers with advanced training or are not currently operating at peak productivity, you can count on our construction material maintenance to help your reliability soar.

- Recruitment and retention

- Skilled, technical workforce

- IIoT technologies

- World-class safety

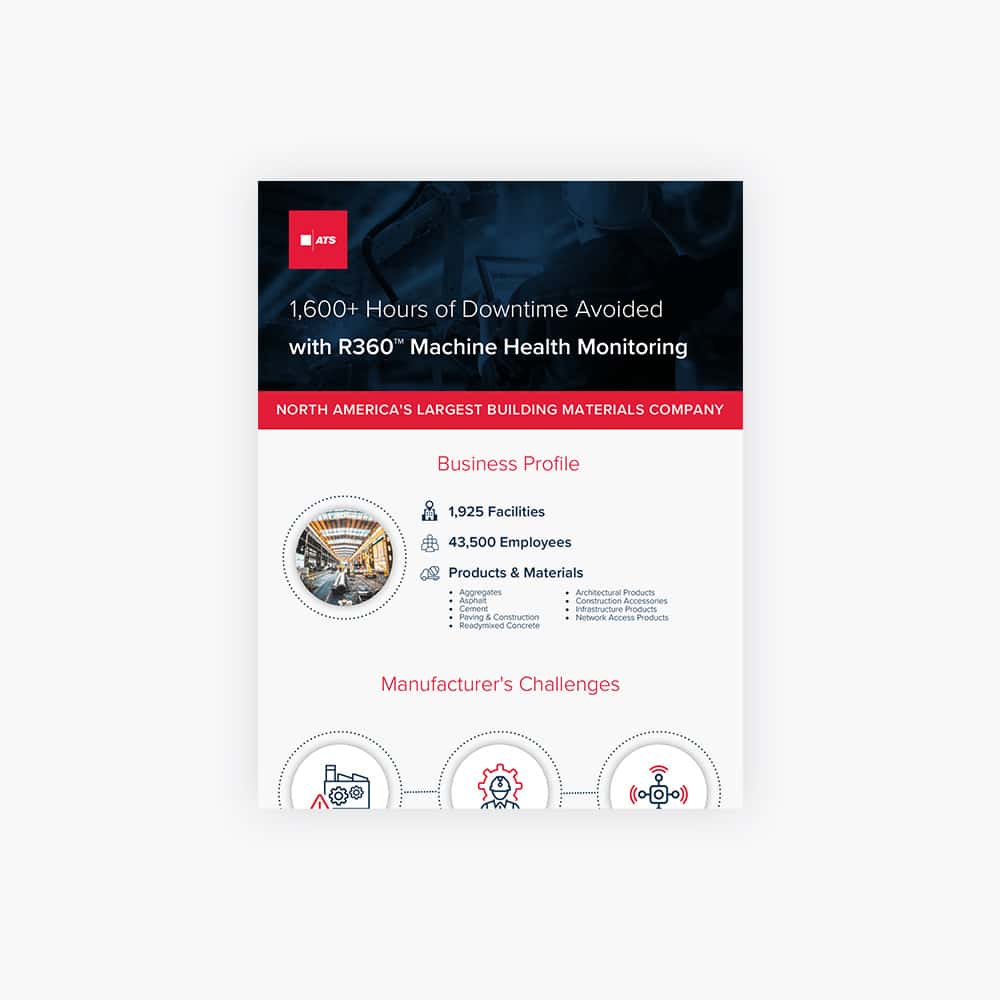

1,600+ Hours of avoided downtime in the first 6 months

After filling technical gaps at one plant, our R360® Machine Health Monitoring Solution was deployed across 100 plants. Discover how implementing this end-to-end solution provided $2.1M in avoided losses.

Building reliability into your manufacturing process

Our maintenance solutions are designed to help manufacturers in the building products industry develop and drive reliability improvements. Our skilled technicians help you staff your plant, maintain your equipment, increase uptime and lower costs.

Lead with a safety mindset

A safe workplace starts with a commitment to safety culture. ATS technicians bring best-in-class safety procedures to your site, helping you prioritize employee well-being while reducing recordable incidents.

-

World-class safety

Our Beyond Zero safety culture prioritizes compliance and employee well-being

-

Low incident rates

ATS has a 50% lower recordable incident rate than industry average

-

Exceed OSHA standards

ATS has an industry-leading OSHA incident rate and regulatory compliance

Construct a better production process

Today’s building products market is feeling the pressure to produce. Manufacturing equipment must operate at peak performance to meet tight schedules and production goals. ATS can help you meet the maintenance challenges that are keeping you from achieving optimal productivity.

Info Sheet