Get productivity rolling

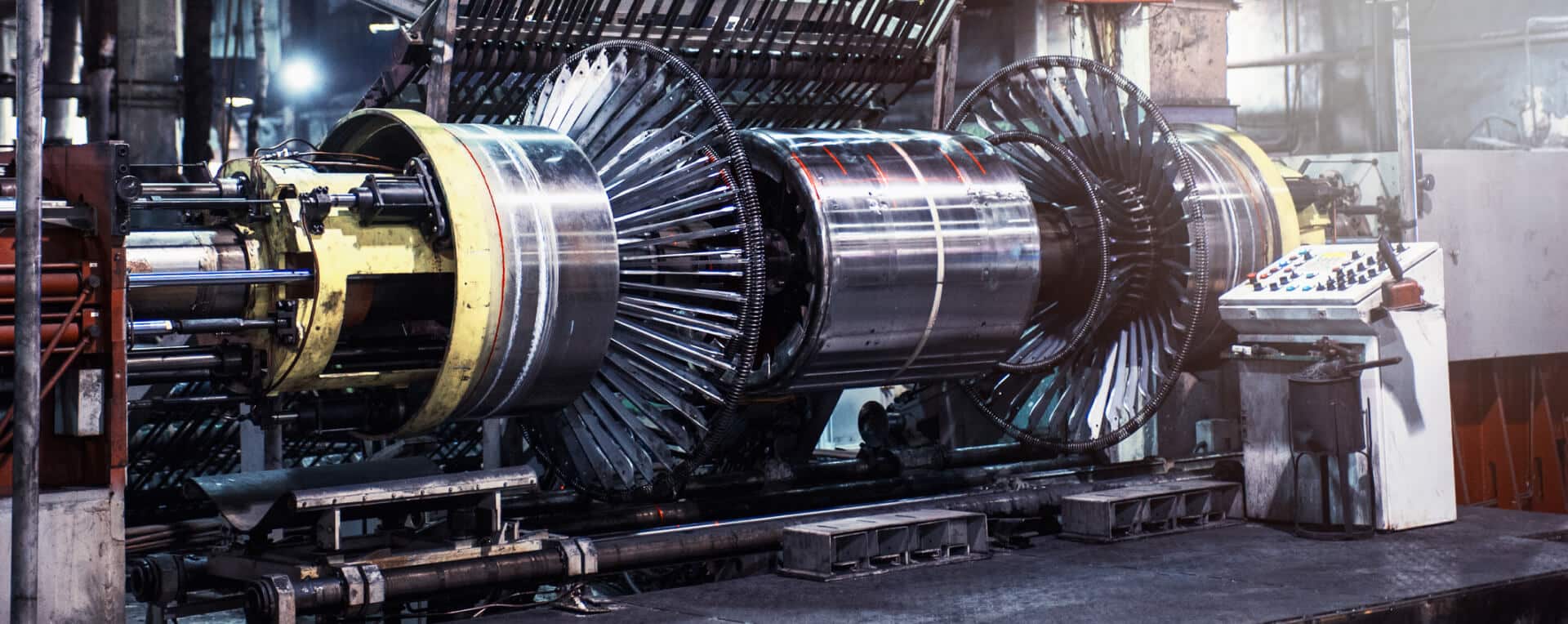

As demand grows, the tire and rubber industry is challenged with producing quality products that meet international standards at the lowest cost. Further, manufacturers must deal with environmental issues such as black and sulfur dust, high temperatures and high humidity that can decrease the reliability and life of their equipment. Our tire and rubber industrial maintenance solutions help increase efficiency and uptime, while our technical training ensures that your workforce knows how to maintain your equipment.

Our expertise in the equipment used in rubber industrial maintenance allows us to help your factory overcome operational challenges while increasing uptime and optimizing productivity. Our knowledge of your tire manufacturing equipment includes, but is not limited to:

Mixers

Cutters

Calenders

Curing Presses

Robots

Assembly Equipment

Materials Handling

Inspection Equipment

“Outsourcing parts management goes beyond stocking parts. It’s about the accuracy of the inventory.”– Leading Tire Manufacturer

Reliability excellence and beyond

Our skilled workforce, established processes and innovative, data-driven technologies combine to help you meet your unique business needs. Whether you lack skilled workers with advanced training or are not currently operating at peak productivity, you can count on our tire and rubber industrial maintenance services to help your reliability soar.

- Proven talent acquisition and retention

- Skilled, technical workforce

- IIoT technologies

- World-class safety

ATS generates $5.7M in savings

One of the world’s leading tire and rubber manufacturers needed to focus on its core competencies – MRO asset management was not one of them. They partnered with ATS, an outsourced company that specialized in storeroom and parts repair management, to improve reliability and lower replacement costs.

Rubber and tire manufacturing maintenance solutions

Our plant management services help keep equipment operating so managers can concentrate on running and growing their businesses. Our skilled technicians help you maintain and repair your machines to reduce downtime, improve efficiency and maximize output.

Lead with a safety mindset

A safe workplace starts with a commitment to safety culture. ATS technicians bring best-in-class safety procedures to your site, helping you prioritize employee well-being while reducing recordable incidents.

-

World-class safety

Our Beyond Zero safety culture prioritizes compliance and employee well-being

-

Low incident rates

ATS has a 50% lower recordable incident rate than industry average

-

Exceed OSHA standards

ATS has an industry-leading OSHA incident rate and regulatory compliance

Achieve your reliability goals

If your machines are down when you need them or you have trouble meeting quality standards, then take advantage of our industrial maintenance and parts services. We’ll help you reduce downtime, develop your workforce, and maintain compliance with quality standards.

Info Sheet