Challenges

In the dynamic landscape of Consumer Packaged Goods (CPG) manufacturing, an efficient storeroom plays a pivotal role in ensuring seamless operations. For one leading pet food manufacturer, plans to implement two new production lines at their plant in Georgia exposed critical parts and storeroom challenges, uncovering over $1 Million in unidentified part losses. Without a proper system in place to track parts, the manufacturer struggled to implement plans for the new production lines and reached out to ATS to source necessary parts and provide storeroom organization expertise.

Solution

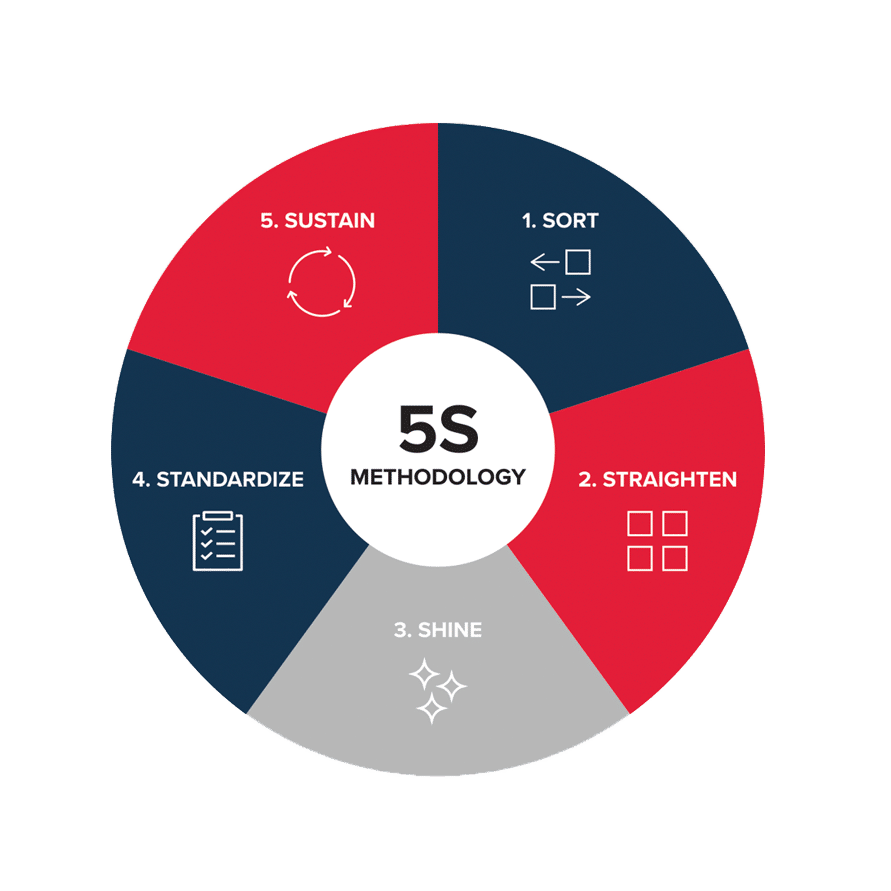

To support the plant, a skilled team of six, including planners and supply chain experts, identified, purchased, and inventoried over 2,700 spare parts for the new production lines. To mitigate additional storeroom challenges, the team implemented a 24/7 crib attendant, a locked gate for controlled access, and optimized the storeroom layout by arranging parts by commodity for better usability while using 5S methodology for sustained storeroom best practices. By coordinating with vendors for reduced prices, bulk order discounts, and utilizing ATS expertise and sourcing network, over $127,000 in cost savings were recognized. The solution not only streamlined internal operations but paved the way for support and improved efficiency at sistering sites, establishing a sustainable approach across facilities.

Results

- $127,000+ in cost savings within 12 months

- Streamlined storeroom efficiency with 5S methodology

- Wall-to-wall inventory identified over 2,000-line items valued at $6.5 million