Your trusted maintenance partner

Our experience

For four decades, we’ve helped hundreds of manufacturers boost efficiency through industrial plant maintenance.

Our mission

Reliability excellence is at the core of everything we do to provide you improved uptime and asset performance.

Our culture

Built on four foundational pillars around safety, people, customers and services – continuous improvement is a focus.

We make factories run better and smarter

We know unplanned downtime, technology integrations and the recruitment and retention of maintenance personnel can put your production at risk. Through our reliability expertise in outsourced maintenance and industrial maintenance and repair, your factory floor will be running like a well-oiled machine.

Our commitment to flexibility, transparency and collaboration is foundational to our success, and we pride ourselves in a work philosophy built upon continuous improvement and thorough alignment to our customers’ business goals. That’s why when we engage with your maintenance process and operations, we don’t just consider you our customer – you’re our partner in production excellence.

Tailored solutions to meet your needs

What's included? | Comprehensive Maintenance Solution | Technical Workforce Solution | Surge Support Services |

Technical Resources | |||

Safety Excellence | |||

Recruitment & Embedded Workforce | |||

SkillPoint™ Technical Training | |||

Planning & Scheduling | |||

Maintenance Ownership | |||

Technical Leadership | |||

ATS Operating System | |||

Reliability 360® Machine Health Monitoring | |||

eFactoryPRO CMMS | |||

MRO Asset Management |

Comprehensive program

When partnering with us for manufacturing maintenance solutions, we take ownership of the leadership, workforce, recruiting and training off your plate so you can focus on core competencies.

- Increase machine availability, uptime and throughput

- Reduce maintenance labor and material costs

- Minimize total cost of ownership

Workforce program

Through our proven strategies, we provide you the skilled technicians and supervisors while you retain ownership of the maintenance strategy.

- Experienced talent recruitment

- Continuous technical training

- Robust employee benefits

Short-term support & projects

Our short-term industrial maintenance services enable you to access support when and where you need it most from reliability experts and multi-craft technicians to machine operators.

- Regional and national coverage

- Proven talent acquisition and retention

- Safety excellence

Trends in industrial manufacturing

In the rapidly advancing manufacturing landscape, four key trends are revolutionizing the future: technology integration, flexibility and adaptability, sustainability initiatives, and balanced automation. Explore our video on manufacturing trends to discover how these developments are shaping the future of the industry.

Comprehensive maintenance: A game changer

A leading heavy equipment manufacturer in Pontiac, IL faced staffing issues, maintenance execution problems and rising past-due shipments. To address these challenges, ATS implemented a comprehensive maintenance program, transforming the site into a paragon of operational excellence. As a result, the manufacturer experienced:

- $14.5M year-to-date cost savings

- 27% increase in machine hours

- 100% PM completion rate

“ATS has been a game-changer for us, ensuring our equipment stays reliable and ready to meet production demands. Their proactive approach and skilled support have made a real impact on our uptime and overall efficiency.”

Overcome industrial maintenance management challenges.

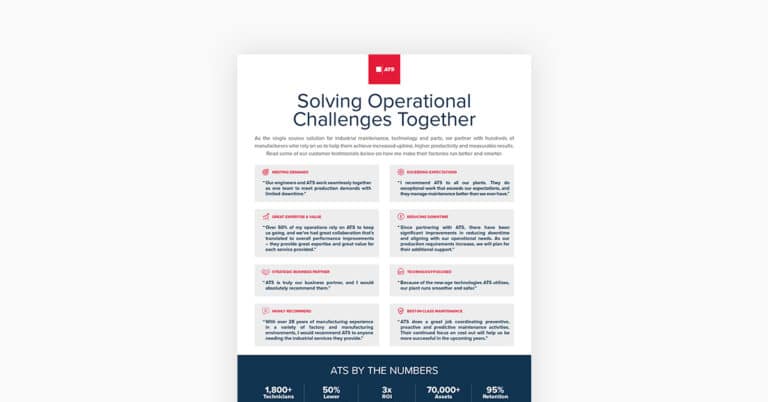

trusted by leading manufacturers

Explore manufacturing maintenance resources

Learn how we take industrial plant maintenance to a new level with our holistic approach to asset reliability from ATS thought leaders and industry experts.

Info Sheet

Industrial maintenance services for manufacturers

As one of the leading industrial maintenance companies, our experience and best-in-class processes deliver measurable results across process and discrete manufacturing, optimizing business functions across organizations.