We can help fill your labour gaps and increase uptime

We know unplanned downtime, technology integrations and the recruitment and retention of maintenance personnel can put your production at risk. Through our reliability expertise in outsourced maintenance and industrial maintenance management, your factory floor will be running like a well-oiled machine.

Should you outsource your maintenance operations?

Outsourced maintenance comes in many shapes and sizes. A facility can choose to outsource its entire maintenance program, or can work with an outsourced maintenance partner to augment short-term needs.

In this blog, learn the different types of industrial maintenance outsourcing and questions you can ask yourself to determine whether it’s a good idea to consider outsourcing some or all of your maintenance operations.

Comprehensive maintenance program

Increase availability, improve productivity and reduce costs with our all-inclusive factory maintenance solution.

Learn more about our comprehensive maintenance program >

Leadership & technical workforce

Skilled maintenance leadership, engineers and multi-craft technicians

Work execution management

Consistent and reliable service quality that improves communication and culture

R360® Machine Health Monitoring

The latest predictive technologies to improve technician and production efficiency

R360® Technology Center

Access the condition monitoring expertise and tools you need to proactively manage machine health

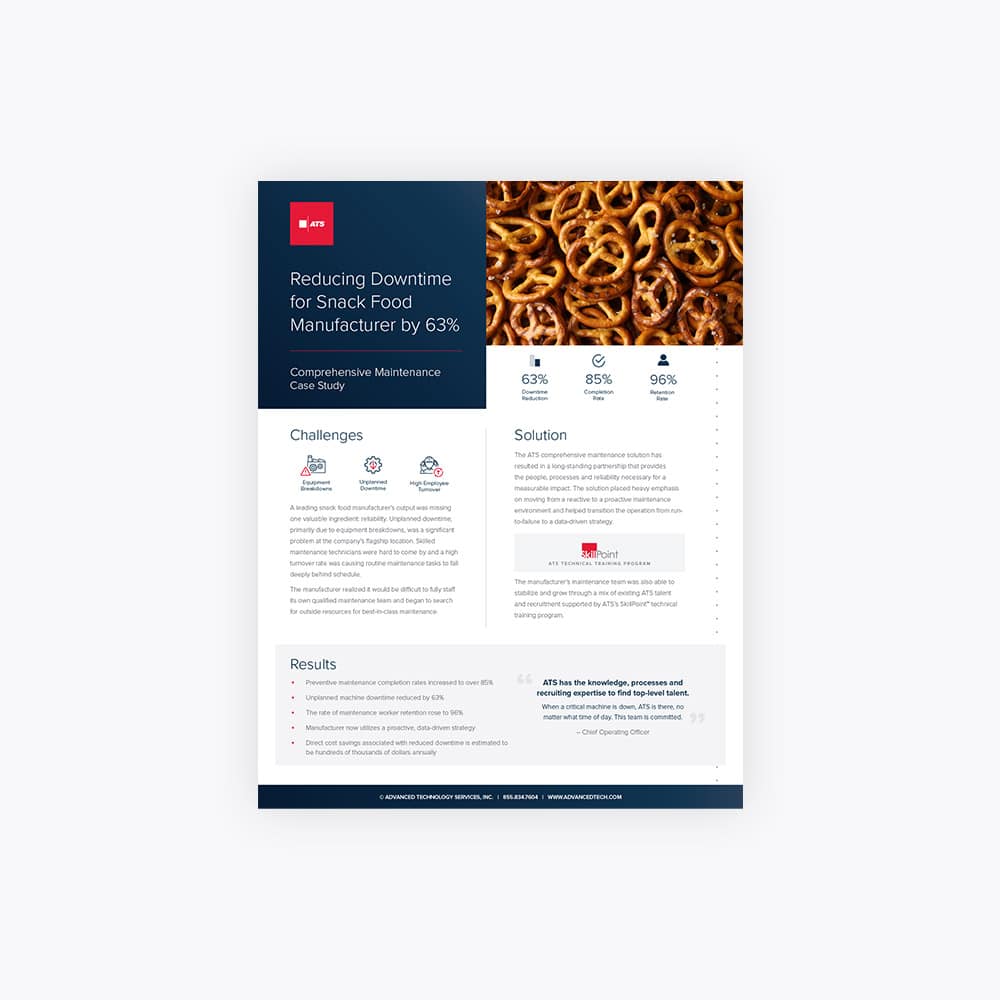

Downtime reduced by 63% for CPG manufacturer

A leading snack food manufacturer was experiencing significant unplanned downtime due to equipment breakdowns and high employee turnover. Our turnkey maintenance program provided immediate results saving the manufacturer time and money.

“ATS has the knowledge, process and recruiting expertise to find top-level talent. When a critical machine is down, ATS is there, no matter what time of day. This team is committed.”