A manufacturing operating system is a major step in the evolution of manufacturing processes and practices in a facility. What is an operating system? It is a framework of interdependent elements — including benchmarks and improvement techniques for each — designed to strive for and result in operational excellence.

A manufacturing management operating system governs all facets of the manufacturing process — providing guidance for decision-making, scheduling, budgeting, maintenance, procurement, validation, quality, fulfillment and more. With the standards set by an industrial operating system, managers and personnel are free to focus on the tasks at hand — maintenance, production, planning and otherwise.

What are the benefits of the ATS Manufacturing Operating System?

Manufacturing operations management systems offer a range of benefits at all levels and functions of the facility, all of which are centered on the (described above) decision-making and enablement framework. In this section, we will look at the tangible benefits that come as a result:

- Consistency and reliability in processes: The industrial operating system takes the guesswork out of processes by developing and applying SOPs (standard operating procedures) for any function that takes place in the facility — from production to maintenance, inventory to procurement, and forecasting and HR. This consistency and reliability allow personnel to focus on carrying out functions at the highest level possible, rather than constantly reinventing the wheel.

- Data-driven objectives and results: One of the key benefits of an operating system is that as a consistent framework, it facilitates a data-driven approach to planning, process development and results analysis. With this data on hand, you are better-equipped to track quality, results and areas for improvement.

- A way to overcome technical skills gaps: A manufacturing operating system can provide a way around skills gaps by providing assistance and guidance in scenarios where personnel specialties and experience may not be on par with what is necessary. By providing a framework, even less-skilled personnel should be able to adequately complete many tasks.

- Alignment with customer goals: Customer goals and objectives are an inherent part of the operating system framework. These goals are identified at the outset of a project, and plugged into the framework, so that there is no chance of crossed signals as to customer expectations.

- Streamlined communication: Communication is a key part of every operating system framework — with documentation, validation and quality checks built into the process. This better ensures a project or process will only move forward when the proper communication channels have been activated every step of the way.

- A unified company culture of excellence: A well-planned, effective management operating system can be a source of support and pride throughout the organization. As the results of the operating system become apparent — improved customer satisfaction, higher productivity and streamlined functions for personnel — employees will develop more and more affinity for the program and the success that it delivers.

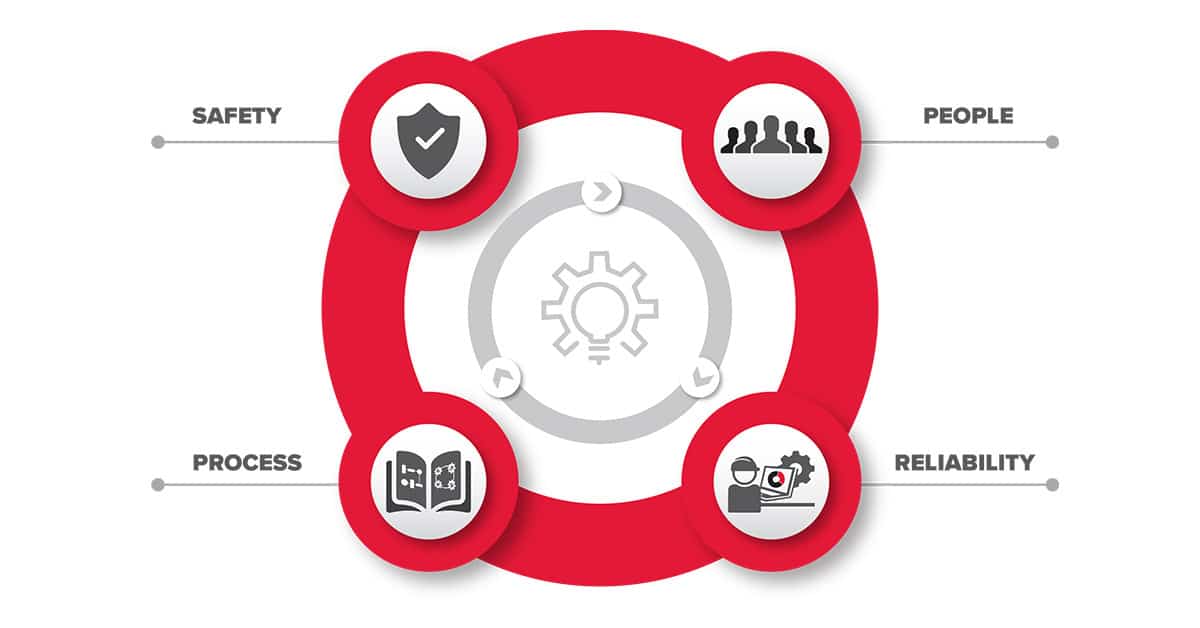

What are the four key pillars?

With an understanding of operating system benefits, we will now take a closer look at the workings of the system.

Most effective operating systems are built on four key pillars, with each pillar reliant on process rather than personnel. With clearly defined objectives, these pillars increase efficiency, productivity and quality — leading to improved overall customer satisfaction. The ATS foundational pillars — and the factors that they comprise — are:

- Safety: Clearly defined safety training and education practices, structured incident investigation, employee involvement and ownership, regular evaluation.

- People: Standardized, transparent results and performance tracking, bottom-up involvement in management and process ownership, built-in education and development through processes.

- Process: Consistently excellent service through well-defined planning and execution, transparent accountability measures, process analytics, root cause analysis, open communication and knowledge transfer.

- Technology: Standardized equipment care and maintenance fundamentals, smart equipment monitoring, failure elimination, custom data-driven planning and action.

Key features of an effective MOS

An effective manufacturing operation system must combine multiple functionalities to streamline your processes. These include:

- Integration Capabilities — When your system communicates and interacts with your existing systems as seamlessly as possible, you can enjoy smoother operations that are as efficient and effective as they can be.

- Real-time monitoring — Collecting data in real time provides manufacturers with all the details they need to plan maintenance tasks, adjust processes and enhance their facilities’ performance for greater productivity.

- User-friendly interface — The easier it is for your employees to use the MOS, the more successful it will be. Having an intuitive interface with a short learning curve helps ensure everyone can get onboard with it without much confusion.

- Cybersecurity — Protecting all the valuable data your MOS will be charged with handling is a high priority. Ensuring the system you choose offers robust cybersecurity measures reduces your risk of data beaches that can have a significant impact on your operations.

Now that you have a better understanding of the role of MOS in manufacturing, you are ready to explore how they can help drive results in your facility. As a leader in industrial maintenance, our ATS Operating System is ready to help take your quality and processes to the next level. Contact us to learn more.