Our storeroom management includes

Data collection & analytics

Gather MRO data across your organization with our AI-powered platform to drive strategic storeroom process improvements and cost savings.

Inventory accuracy & reporting

Ensure parts are in the right place at the right time with onsite ATS crib attendants and 5S methodology.

MRO storeroom efficiency

Drive continuous improvement and cost savings with a properly stocked, organized and maintained maintenance storeroom.

Your storeroom could be hiding avoidable costs

In many factories, the parts crib is an afterthought. But we know it’s a place where savings, greater productivity and improved performance can be found—enough to impact your entire manufacturing operation. Our storeroom management services help drive efficiency, minimize downtime due to lack of parts, improve technician utilization and increase business insights through monthly reporting and AI-powered technology.

Comprised of several material management disciplines, our solution is a powerful way to drive MRO to a new level of value. Our on-site program brings parts standardization, greater efficiencies and cost savings to your overall manufacturing operation. With fully trained ATS personnel staffed in your storeroom, you will have the process expertise and equipment know-how to right-size your inventory, improve parts tracking and distribution, reduce inventory spend and extend the life of your machines.

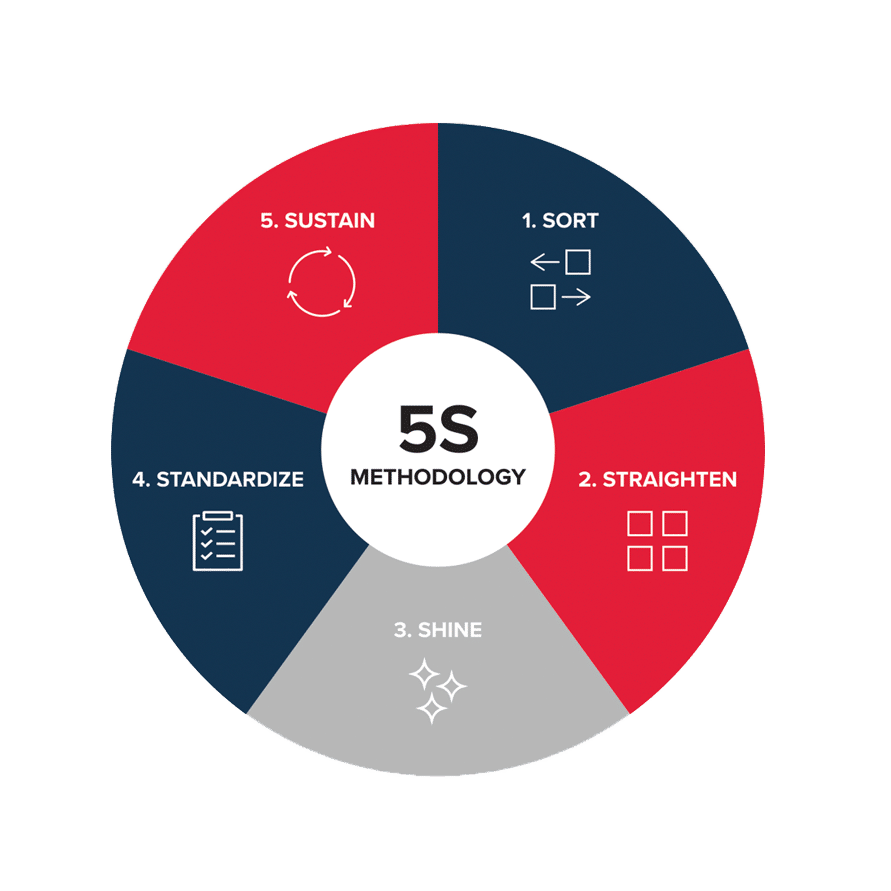

5S methodology

Putting the 5S’s into practice maximizes use of available space and reduces overall inventory cost by stocking only the parts that have the greatest impact on operations. When properly stocked, organized and maintained, parts cribs are an invaluable aid to continuous improvement initiatives. They can save a manufacturer thousands, if not millions, of dollars over time.

- Removes excess/obsolete parts and cleans/organizes the storeroom

- Standardizes documentation and implements processes

- Promotes a culture of continuous improvement

Eliminate common MRO challenges

ATS brings together data from your business units and ERP, EAM, or P2P systems and turns that data into actionable insights. We can help you achieve network-wide material visibility, reduce search and order costs, improve service levels and strengthen alignment between operations and procurement.

- Harmonize MRO data across plants, systems and teams

- Optimize existing inventory levels while reducing risk

- Gain visibility to MRO materials across your networks

- Capture team expertise & knowledge

- Proactively address tail spend reduction opportunities

- Onboard quickly and unlock value within 60 days

Optimize your storeroom with a technology-driven solution

Explore MRO storeroom resources

Learn how we take storeroom efficiency to a new level with our comprehensive approach to maintenance storeroom management.

Info Sheet

MRO storeroom management for manufacturers

Our storeroom solutions and best-in-class processes deliver measurable results across process and discrete manufacturing, optimizing business functions across organizations.