Smarter strategies, better results

Manufacturers face daily pressures and challenges, making it difficult to allocate the time or resources needed to implement new technology in their plants. Partnering with an outsourced technology provider like ATS for maintenance in Industry 4.0 eases the burden on manufacturers.

Reliability experts can help leverage technology to their advantage, using data-driven insights to predict impending work and prevent unplanned downtime. Help drive uptime with machine health monitoring, ROI guaranteed.

Get started

Complete the form below, and upon submitting, you can choose to schedule a meeting with an ATS representative either the same day or at a convenient time.

Proven expertise, guaranteed results

ROI Guaranteed

Confidently invest in new technology, ROI guaranteed.

Over 4 in 5 manufacturers

Continue with ATS for long-term, reliable machine health monitoring.

alert-to-recommendation ratio

With prescriptive actions delivered by expert analysts within hours.

Powering smarter factories with a market-leading connected platform

Industrial technology is driving new standards for manufacturing efficiency—but without proper technical expertise, the value of technology can diminish significantly. Through advanced machine monitoring, data analytics and prescriptive actions, our industrial technology services provide you with a scalable solution that identifies potential condition issues before an unexpected failure occurs.

With our IIoT solutions connecting all the systems in your facility, you can experience reduced downtime, extended equipment lifespans and overall improvements in your operations. We leverage our expertise in manufacturing technology solutions to help you implement a fully-integrated system that provides exceptional efficiency and enhanced performance.

R360® Machine Health Monitoring

Our solution delivers proactive condition monitoring through data analytics and prescriptive actions for on-site technicians.

Remote diagnostics

Our centralized R360® Technology Center is at the core of real-time monitoring and rapid improvement events.

CMMS Integration

With our API integration, you can seamlessly send work orders, labor and material costs, machine history and regulatory compliance data between the R360® dashboard and your CMMS.

Subject matter expert network

Access a network of reliability engineers and maintenance technicians in the field with specialized expertise.

Technician hub

This online resource offers OEM manuals, troubleshooting guides and best practices for field technicians.

Industrial parts

Streamline your part and supply needs—repair, surplus and new—all supported by our state-of-the-art service center that helps get your equipment back up and running.

Field services

Gain access to skilled, multi-craft technicians who deliver on-site maintenance support.

From your machines to our technology center

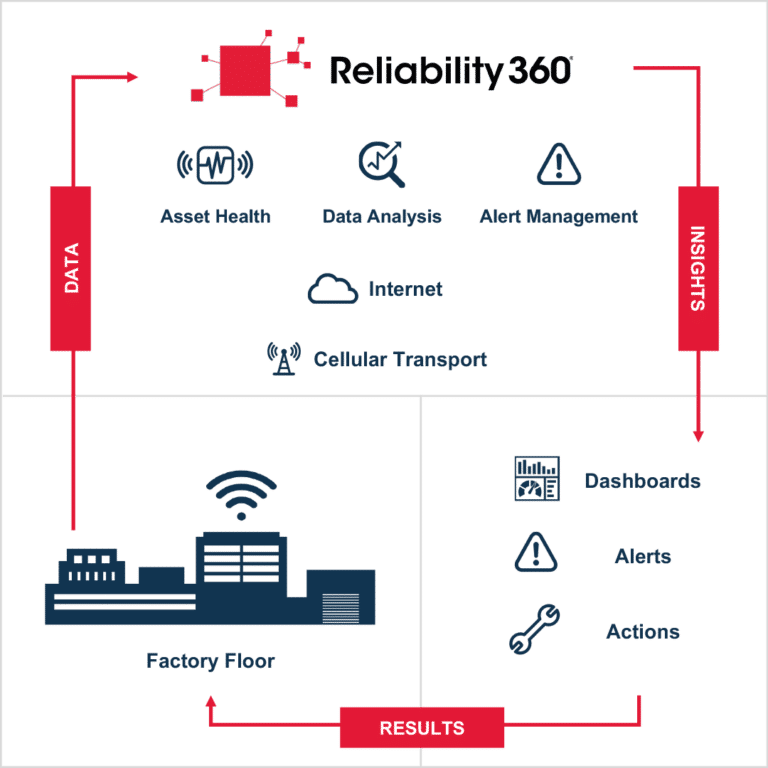

Within a smarter factory, machine data and insights drive productivity and enable a more predictive, reliability-centered maintenance program.

Our R360® Technology Center is designed around Industrial IoT, remote maintenance monitoring and sensor technologies drawing data from connected devices on your equipment. This real-time asset monitoring notifies our condition monitoring experts of potential machine health issues, before affecting production and causing unplanned downtime – delivering increased uptime and avoided losses.

Eliminate common MRO challenges

ATS brings together data from your business units and ERP, EAM, or P2P systems and turns that data into actionable insights. We can help you achieve network-wide material visibility, reduce search and order costs, improve service levels and strengthen alignment between operations and procurement.

- Harmonize MRO data across plants, systems and teams

- Optimize existing inventory levels while reducing risk

- Gain visibility to MRO materials across your networks

- Capture team expertise & knowledge

- Proactively address tail spend reduction opportunities

- Onboard quickly and unlock value within 60 days