References to the industrial internet of things (IIoT) are everywhere.

It’s hard to find anything written in the last few years related to smart manufacturing, supply chain transformation, logistics, transportation, factory automation, data collection, etc. that doesn’t reference IoT or IIoT in some related context. IIoT is making big waves in the manufacturing industry – primarily on the factory floor. At the heart of many IIoT-related solutions utilized by manufacturers are sensors. For those who have yet to implement this technology at your facility, you may be asking yourself; is it best to sense or not to sense?

To help determine if your plant is ready to implement, it’s important to understand why IIoT manufacturing technologies have taken off. Although there are many, the following are four key benefits of IIoT that illustrate why companies are increasingly implementing IIoT-enabled solutions in their factories.

Lower hardware cost

In the past, the need for multiple sensors and various hardware devices made strategic installation on a larger scale cost prohibitive and many manufacturers struggled to see the value in using an incredibly expensive device to provide very little information. That’s simply not the case today. Due to mass production, hardware costs are down significantly, and successful cost-saving results have guided the demand for IIoT integration upward. The biggest challenge plant leadership faces today is determining what kind of sensor to invest in, where it would be best utilized, and which parameters need to be set in place to achieve the most valuable data.

Market expansion

More IIoT-ready devices and sensors with capabilities to measure pressure, proximity, contact, vibration, displacement, location, velocity, temperature, current, etc. are coming to the market daily – all with a variety of inputs such as electromagnetic, photoelectric, optical, radio and other signals. These sensors can also communicate with various types of ethernet, wireless and Bluetooth protocols. Because of this technology influx, the IIoT-device market has become saturated with multiple variations of each type of sensor. Research will play a key part in determining which brand and sensor type will work best for your organization.

Availability of software analytics tools

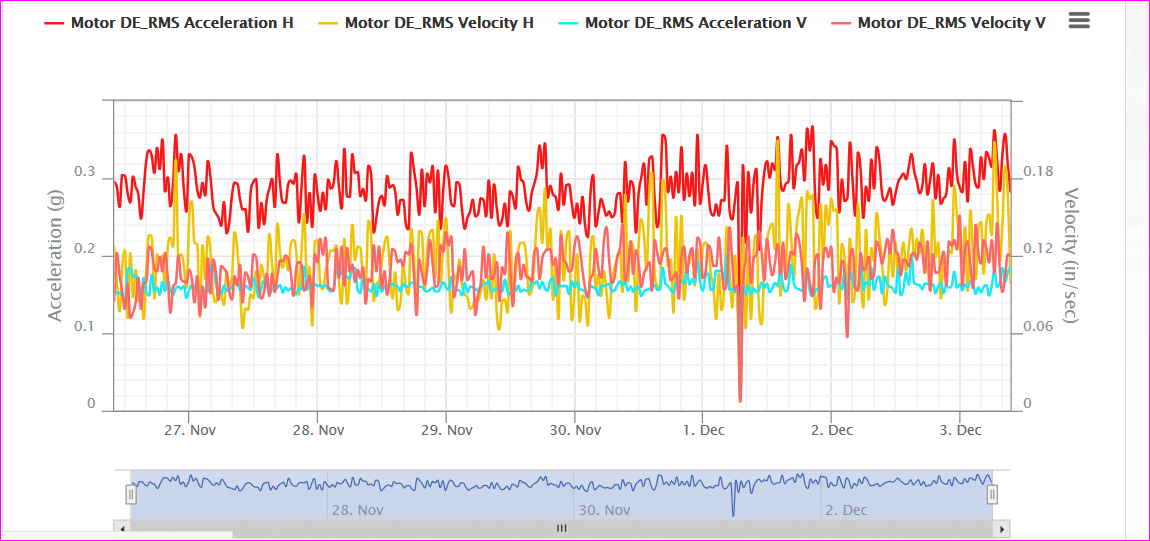

Software analytics tools vary greatly in overall capabilities, but all provide numerous IIoT benefits of potential value. By utilizing these tools where real-time data is available, it is possible to construct algorithms to predict and monitor real-time scenarios and take corrective actions instantly. This is one of the biggest value propositions for using this IIoT manufacturing technology. Below is a screenshot of vibration data from a sensor placed on a critical motor.

With analysis and interpretation, it’s easy to get lost in the data output and take on more than your plant can handle. When faced with this influx of information, step back and ask yourself the following questions:

- What team of top-talent engineers in my organization is going to be dedicated to monitoring this information 24/7?

- What corrective action tasks can be identified from the data we gather?

- If there isn’t someone on staff today, what are the benefits to employing someone who can read the data?

To avoid data overload, determining key performance indicators at your facility prior to adopting sensor technology will help weed down the information presented after implication.

Interconnected hardware and access to information

Real-time monitoring combined with accessible cloud-based services to record data opens many opportunities for process improvement. Cloud-based services have significantly changed manufacturing’s utilization and justification of IIoT manufacturing technology, and the data collected can be used to set goals for improved plant efficiency, reliability and production. Universal internet connectivity has made to information easy, fast and relatively cheap to get. However, the question remains if your plant has the internal capacity to manage and maintain this technology.

Rather than taking on these challenges in addition to your day-to-day activities, consider working with a third-party IIoT company that specializes in data collection, sensors and improved asset performance. When determining if your plant is ready to utilize the IIoT, careful consideration is key. Companies researching this technology should carefully weigh the value of the information collected from their factory. They should have a detailed answer to the question, “What do we intend to do with that information collected to improve the productivity of our factory?”. Don’t do technology for technology’s sake. If you don’t have a clear answer question or are not aware of how to make sense of the data collected, consult a third-party who specializes in industrial maintenance and asset performance for support.

The change in cost and capabilities to implement the Industrial Internet of Things has come a long way. Low-cost wireless sensors combined with the analytics and communication mediums available on the factory floor today make it a viable, cost-effective tool that can drive down production costs and improve overall profitability. In addition to being smart about research and strategy, you must be willing, to be honest in reference to your company’s technology strengths and weaknesses.

Take advantage of your company’s identified strengths and rely on reliability experts to help in the areas of weakness. In the end, there’s really no question when it comes to the question, “to sense or not to sense.” For more information about how Advanced Technology Services (ATS) utilizes IIoT sensors to help our customers capture equipment data, analyze it and implement improvements to drive increased uptime, contact us today.