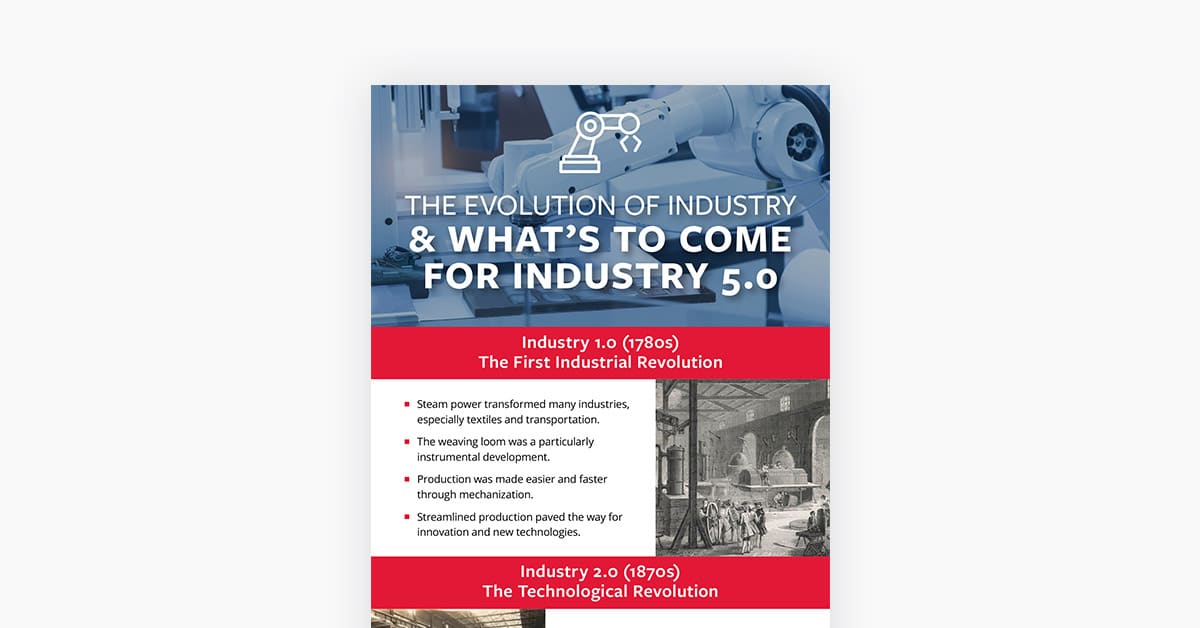

Technology has expanded in leaps and bounds since the First Industrial Revolution. Early on, the advancements made were tied heavily to the needs of humans at the time. Today, we’re experiencing how the needs of modern life are really driving innovation and accelerating society into the future. Below, we’ll briefly explore how the technology of today is quickly propelling us into the next industrial revolution.

Since crossing into the 21st century, we’ve seen computers and subsequent digitalization enhance our technological capabilities more than a hundred-fold. This period of computer technology has changed how we exchange information, communicate and work. Much of this is thanks to the introduction of advanced data analytics, the Internet of Things (IoT), cloud computing, artificial intelligence (AI) technologies and machine learning.

With the emergence of these still-developing advancements, our industrial capacities have improved to the point of automation, cyber-physical systems and robotics giving shape to smart factories. Such smart factories across the world have enhanced a variety of manufacturing industries, such as automotive and consumer electronics. With humans and machines working together, it has improved overall production, performance and sustainability.

While many companies and entire industries are still in the middle of this fourth revolution that started in 2011, Industry 5.0 is on the horizon. Becoming known as the era of personalization, the next industrial revolution is projected to further augment the collaboration of humans and machines. By syncing technological advancements with human thinking skills, a more personalized experience will shape production as well as our day-to-day lives.

When looking at the current utilization of cognitive computing and interconnectivity via cloud servers, IoT-enabled smart facilities may be shifting focus to the return of the “human touch” into the industrial framework. In other words, Industry 5.0 will expand on the use of human-centric robots in industrial work via individually tailored devices. The result is a personal, cooperative and supportive approach, not to supersede humans as some advancements in Industry 4.0 have done.

Such reconciliation of man and machine aims to improve the means of production as well as efficiency through human-centric, resilience and sustainability strategies. Achieving this is done by putting human, environmental and social aspects at the forefront of production. With wearables, robotics, autonomous vehicles, additive manufacturing, virtual reality and connected technologies leading the way, Industry 5.0 has already started to gain traction. As more and more businesses shift their focus from Industry 4.0 to incorporating the new ideas emerging from 5.0, we’ll see the technology go places we never thought imaginable.

Want to learn more about Industry 5.0 and the other industrial revolutions? Check out the accompanying resource for more information. Contact ATS to learn more about our technology-driven industrial maintenance services.