Electrical monitoring

Identify factors that indicate pending electrical failure and fix the issue before it poses a danger

Leak detection

Discover equipment leaks so you can repair them well before they cause unplanned downtime

Temperature analysis

Heat flow patterns reveal areas of abnormally high temperature, aiding in predictive maintenance

Detect problems early with infrared electrical testing

Temperature changes are an early sign that problems are developing inside production equipment. With decades of industrial maintenance experience and technical expertise, our electrical thermography inspection services utilizing thermal imaging cameras offer manufacturers a proactive method for planning repairs before breakdowns cause expected downtime and reduce overall equipment effectiveness (OEE).

Thermographic inspection of electrical equipment can help your lower maintenance costs, extend the life of production machinery by preventing or reducing heat damage, and improve safety within the facility. Other benefits of our thermographic inspection services include early detection of failures through identifying hot spots earlier than with other methods. We also can help improve energy efficiency by spotting areas that need more insulation. Detecting electrical components that are overheating also enhances safety by preventing fires or malfunctions. Let us help you replace your reactive maintenance procedures with an effective predictive strategy.

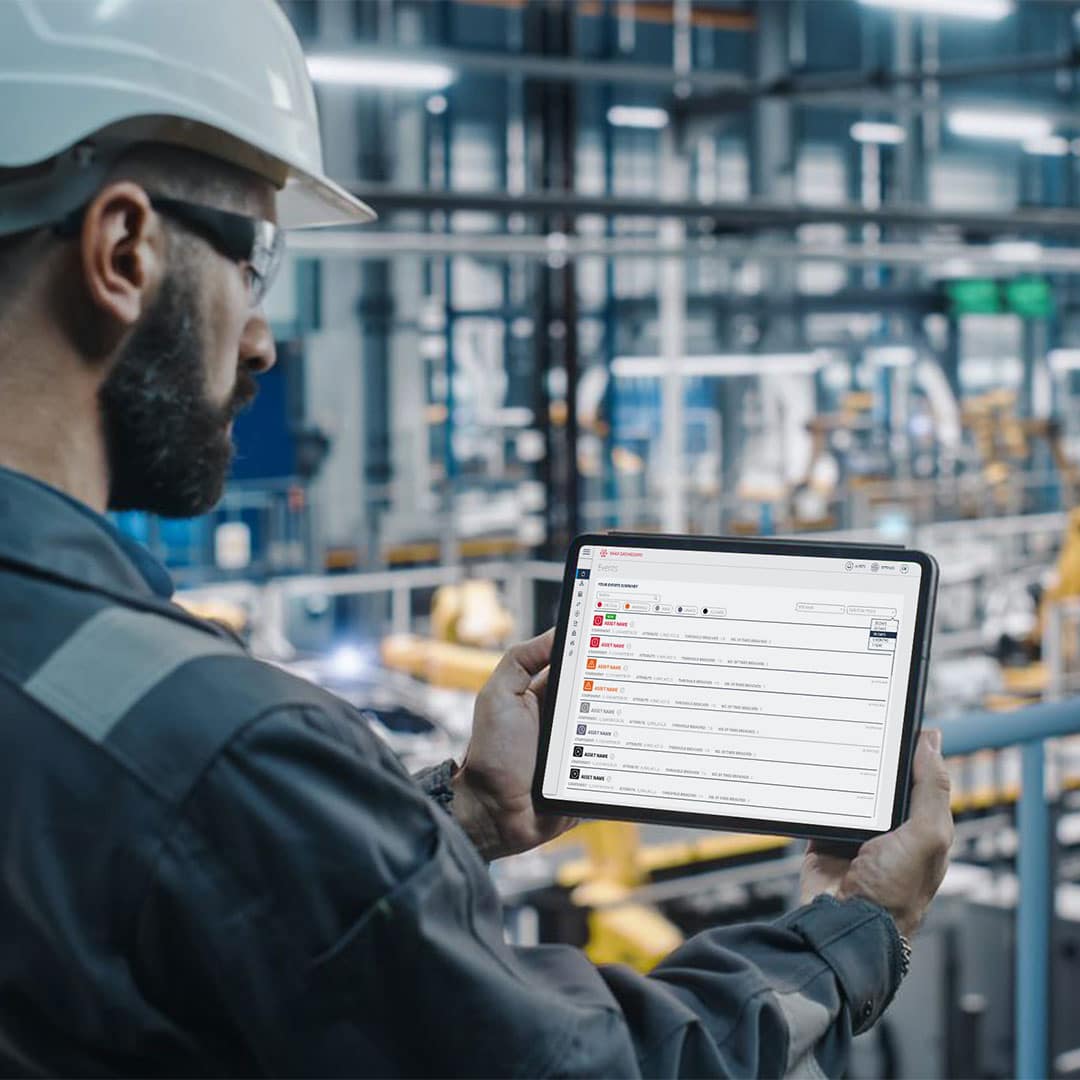

End-to-end IIoT solution

We leverage nearly four decades of maintenance and reliability experience paired with the latest predictive maintenance technologies to prevent unplanned downtime.

- Consultation & installation

- 24/7 condition monitoring

- Predictive maintenance sensors

- Real-time alerts

- Prescriptive actions

- Measurable results

- Optional maintenance & parts support

Our thermographic testing technology integrates with existing maintenance systems and can be tailored to your specific needs, scaling as your business grows.

Get proactive with thermography maintenance

Thermographic inspection resources

Learn more about industrial thermography testing and the role of sensor technology in predictive maintenance.

Thermography maintenance services for manufacturers

Our skilled, highly trained and experienced technicians can capture and analyze the data-driven metrics provided by our infrared thermography inspection services – increasing asset reliability and improving productivity while saving time and money.