Power up your productivity

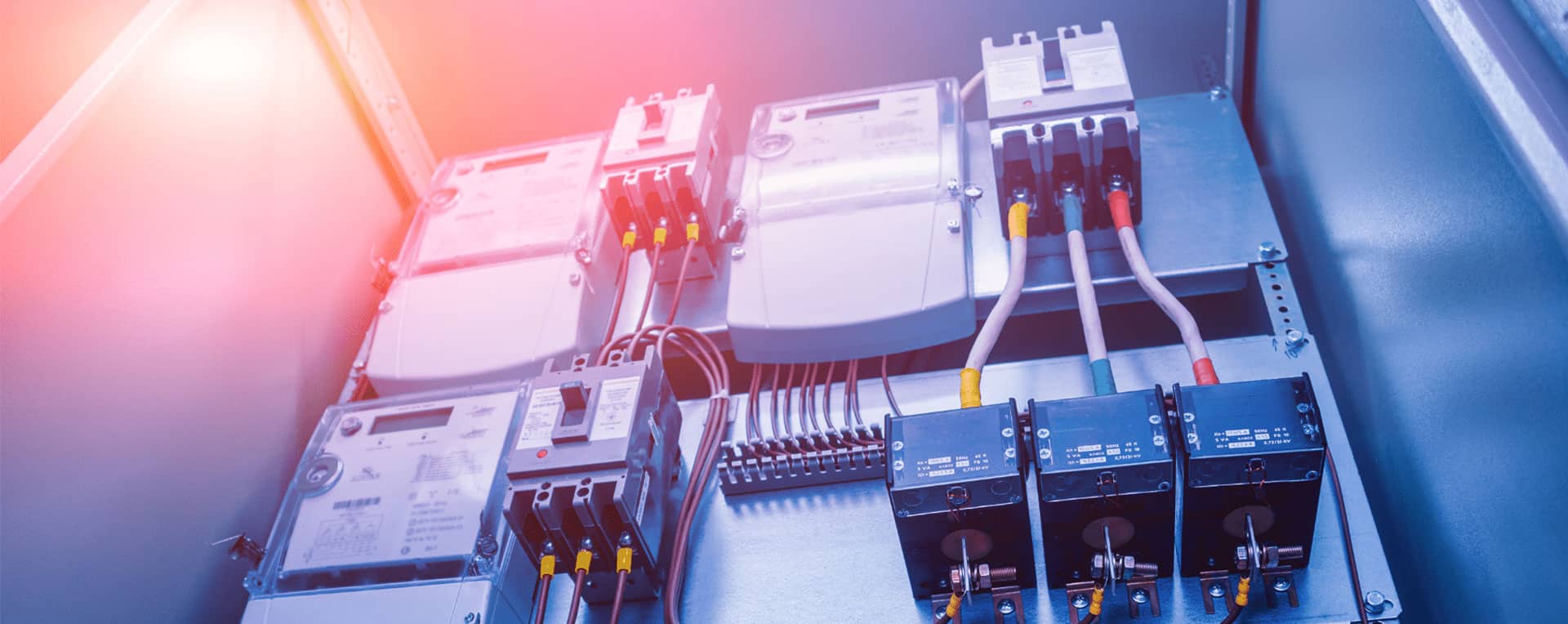

As demand for cost-effective power grows, power distribution operation and maintenance become more complex. Our advanced preventive and predictive power distribution maintenance services help you minimize equipment failures and maximize uptime. This industry also faces the loss of in-house knowledge and specialized technical skills as maintenance technicians retire. Our highly trained, experienced workforce delivers quality industrial maintenance and parts management to help you maximize performance.

Our expertise in the equipment used in power distribution operation and maintenance allows us to help your factory overcome operational challenges while increasing uptime and optimizing productivity. Our knowledge of your equipment includes, but is not limited to:

Punch Pressess

Dies

Press Breaks

Hydraulic Presses

Robots

Testing Equipment

Wire Winders

Solders/Welders

“Any of our plants I visit, I recommend ATS. They do exceptional work, exceed our expectations and manage maintenance better than we ever have.”– Leading Power Systems Manufacturer

Reliability excellence and beyond

Our skilled workforce, established processes and innovative, data-driven technologies combine to help you meet your unique business needs. Whether you lack skilled workers with advanced training or are not currently operating at peak productivity, you can count on our power distribution maintenance services to help your reliability soar.

- Recruitment and retention

- Skilled, technical workforce

- IIoT technologies

- World-class safety

Continuous improvements save $200K+

A leading power distribution manufacturer experienced unexpected failures on critical machines. Our continuous improvements increased critical asset uptime and reduced costs, resulting in $200K+ in labor and cost savings.

Advanced maintenance skills and solutions

We offer technology-driven solutions and skilled technicians through our power distribution maintenance services. Our solutions are designed to help you optimize asset availability and increase performance and productivity — efficiently and cost-effectively.

Lead with a safety mindset

A safe workplace starts with a commitment to safety culture. ATS technicians bring best-in-class safety procedures to your site, helping you prioritize employee well-being while reducing recordable incidents.

-

World-class safety

Our Beyond Zero safety culture prioritizes compliance and employee well-being

-

Low incident rates

ATS has a 50% lower recordable incident rate than industry average

-

Exceed OSHA standards

ATS has an industry-leading OSHA incident rate and regulatory compliance

Optimize plant operation and maintenance

Without the proper maintenance strategies, highly skilled in-house workforce and smart technology, how will you enhance maintenance and improve reliability? ATS has the knowledge, experience, technology and technicians to help you achieve optimal productivity.

Info Sheet