Our expertise drives your productivity

As demand for new vehicles surges, manufacturers strive to prevent costly downtime by managing overall equipment effectiveness (OEE). Our technology-based automotive predictive and preventive maintenance services provide the technology and reliability you need to drive operational efficiency and increase throughput to meet production goals. With four decades of experience in automotive industrial maintenance we know how to keep your equipment up and running through our skilled technicians and predictive technologies for continual production efficiency.

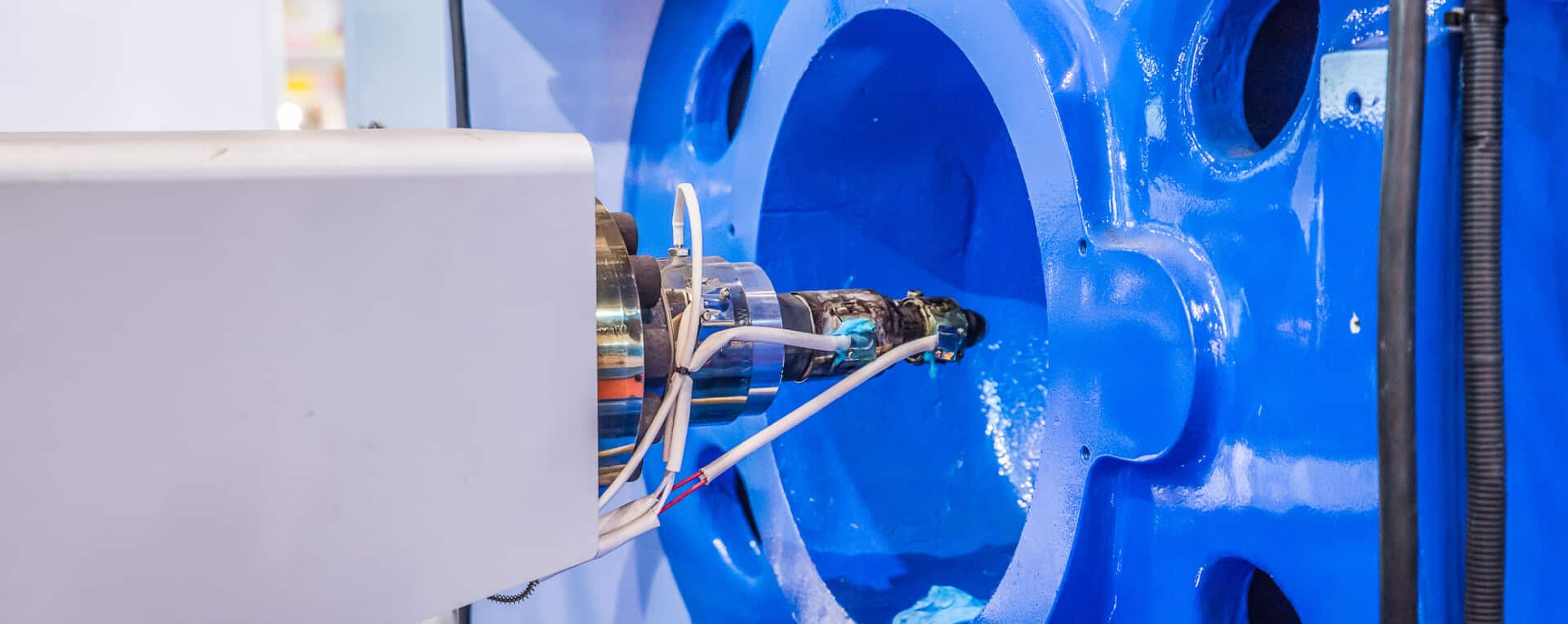

Our expertise in the equipment used in our automotive industrial services allows us to help your factory overcome operational challenges while increasing uptime and optimizing productivity. Our knowledge of your automotive manufacturing equipment includes, but is not limited to:

Robotics

Stamping Presses

Injection Molding

Assembly Equipment

Air Tools

Ovens

Washing Systems

Inspection Tools

“Over 50% of my operation relies on ATS to keep us going – they provide great expertise and great value.”– Leading Automotive Manufacturer

TRUSTED BY leading manufacTURERS

Reliability excellence and beyond

Our skilled workforce, established processes and innovative, data-driven technologies combine to help you meet your unique business needs. Whether you lack skilled workers with advanced training or are not currently operating at peak productivity, you can count on our automotive industrial maintenance solutions to help your reliability soar.

- Recruitment and retention

- Skilled, technical workforce

- IIoT technologies

- World-class safety

Downtime reduced by 22% for luxury automaker

Nothing hits the brakes harder at an automobile assembly plant than downtime. ATS helped reduce production line reliability issues that cost a luxury automaker up to $16,000 per minute.

“ATS has become a valuable and trusted partner. The possibilities for ATS with our company are limitless”

Automotive factory maintenance solutions

Our automotive industrial solutions are geared to your unique maintenance processes and needs. We offer a full suite of services to help you maximize OEE while controlling costs, reducing downtime and optimizing productivity. We provide preventive maintenance services including routine inspections, calibration and component replacements to extend equipment life and reduce your operational costs. We’re also experts when it comes to predictive maintenance in the automotive industry. We utilize advanced data analytics and IoT technology to predict potential equipment failures before they occur, preventing downtime.

Lead with a safety mindset

A safe workplace starts with a commitment to safety culture. ATS technicians bring best-in-class safety procedures to your site, helping you prioritize employee well-being while reducing recordable incidents.

-

World-class safety

Our Beyond Zero safety culture prioritizes compliance and employee well-being

-

Low incident rates

ATS has a 50% lower recordable incident rate than industry average

-

Exceed OSHA standards

ATS has an industry-leading OSHA incident rate and regulatory compliance

Put OEE in the driver’s seat

Automobile suppliers and manufacturers are under intense pressure to meet production targets. Our proven reliability and maintenance solutions drive uptime, improve production efficiency, and help you retain skilled technicians.

Info Sheet