Consistent quality

Vibration monitoring keeps rotating equipment in top condition for consistent quality

Extended machinery life

Analysis allows you to identify vibration abnormalities and repair before a failure

Proactive versus reactive

Utilize maintenance resources more efficiently and optimize parts inventory

Industrial vibration analysis reaps rewards

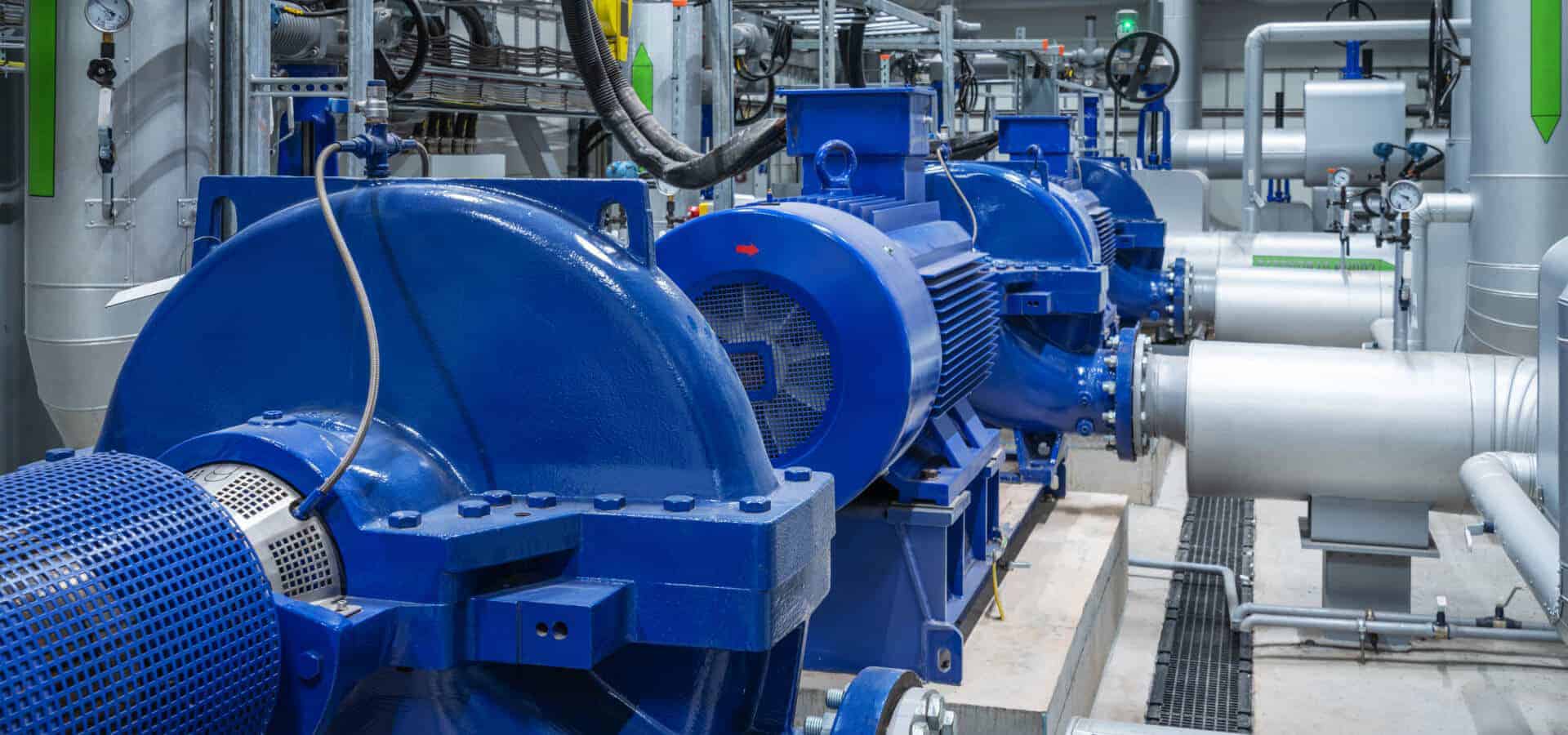

Condition monitoring vibration analysis is an effective method of predictive maintenance for rotating equipment – pumps, motors, gearboxes, machine tools and more. Vibration spectrum monitoring measures and transmits data about the vibration of key components to identify early signs of equipment failure. Our predictive maintenance vibration analysis service monitors performance and detects and fixes issues before they lead to equipment damage and costly downtime. Although vibration measurement services represent an investment, it can save you money in the long run compared to having to fix broken machinery.

Our remote vibration monitoring services help you avoid quality and breakdown issues. Regularly monitoring and tracking changes over time gives you the ability to anticipate when shafts, couplings and bearings need replacing — let our skilled technicians in machine vibration analysis help improve your uptime.

Some of the most common applications and uses for vibration monitoring include:

Bearing wear

Misalignment or imbalance

Rotating machinery

Structural integrity

End-to-end IIoT solution

As one of the leading vibration analysis companies, we leverage four decades of maintenance and reliability experience paired with the latest predictive maintenance technologies to prevent unplanned downtime. We provide and install machine health monitoring systems to enable remote vibration analysis for your equipment so you can always have a complete overview of your machinery’s health and condition.

- Consultation & installation

- 24/7 condition monitoring

- Real-time alerts

- Prescriptive actions

- Measurable results

- Optional maintenance & parts support

Keep rotating machinery running the right way

Vibration analysis resources

Learn more about vibration analysis and the increasing role of predictive maintenance technologies.

Vibration analysis services for manufacturers

Monitoring the vibration of motors, pumps, compressors, fans, blowers and other equipment helps eliminate unplanned downtime, maintain product quality and extend equipment life.