Downtime Stops Here

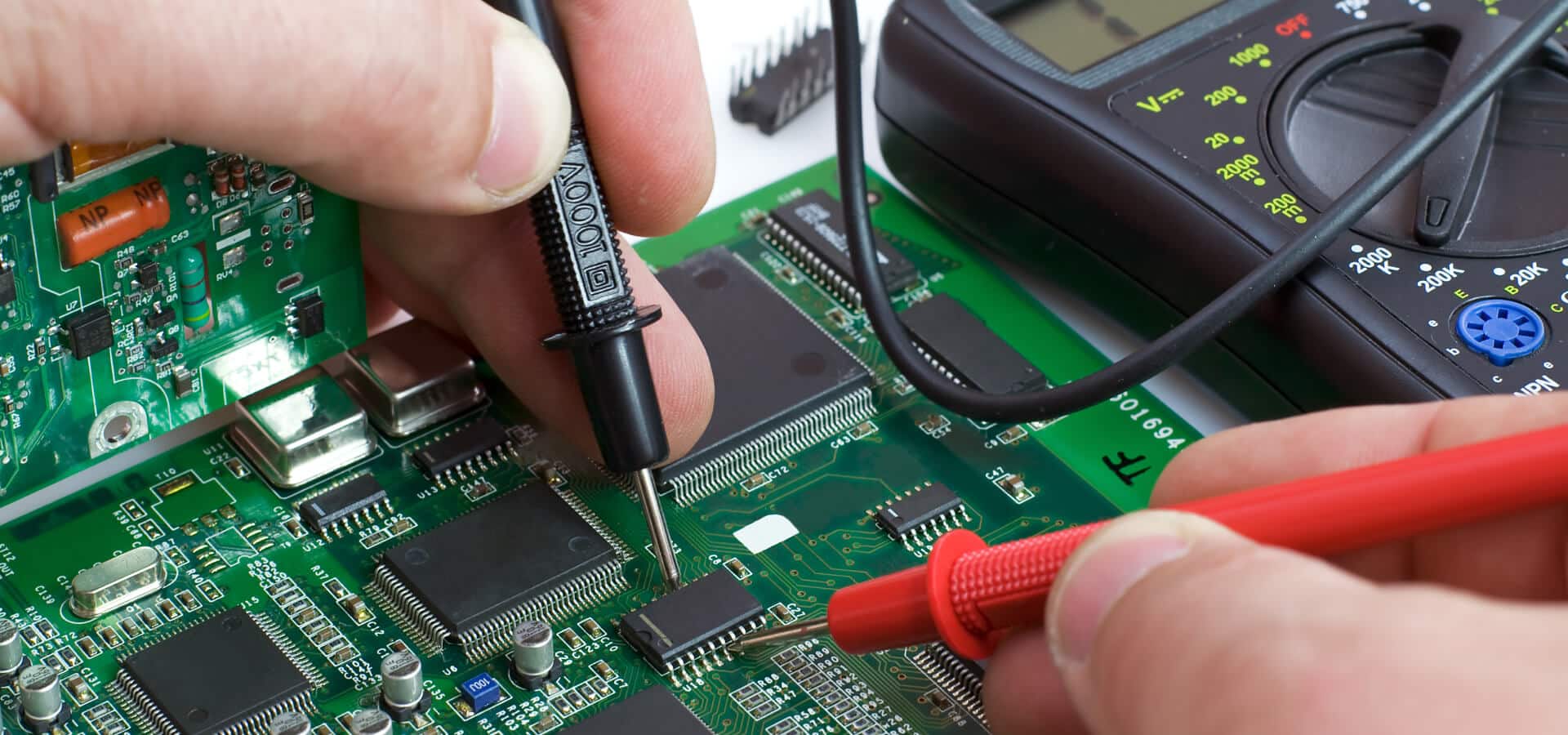

When equipment’s run for decades, routine maintenance may not be enough. Aging equipment can bring hard to solve challenges, such as sourcing and repairing obsolete parts and finding skilled technicians to keep them running.

Since 1985, leading manufacturers have trusted ATS to minimize unplanned downtime, extend the life of legacy equipment and provide multi-craft technicians who follow best-in-class safety standards.

Our approach drives meaningful value, including:

- Reliable part repairs extend product operating life by 200%

- 50% cost savings when repairing parts versus buying new

- 50% lower recordable incident rate than industry standard

Solutions to optimize asset reliability

Comprehensive maintenance

Increase availability, improve productivity and reduce costs with our all-inclusive factory maintenance solution

Technical workforce

Access technical support aligned with your maintenance strategy and boost uptime through our workforce program

Short-term support

Adapt quickly to production needs and fill skills gaps with our short-term maintenance support

Reliability 360® Machine Health Monitoring

The latest predictive technologies to boost factory maintenance, technician and production efficiency

“Over 50% of my operations rely on ATS to keep us going – they provide great expertise and great value for each service provided.”– lEADING AUTOMOTIVE MANUFACTURER

trusted by leading manufacturers