The use of collaborative robots in manufacturing continues to be on the rise, with advances in robot technology driving innovation in nearly every area of the manufacturing facility. Industrial cobots — collaborative robots — are expanding the possibilities of automation in numerous functions. Those functions include maintenance, machine tending, material handling, quality control, material removal and more.

Many of the most effective applications of cobots in manufacturing are done in tandem with human workers, with robots accomplishing the dullest, most dangerous and dirty tasks, while employees complete the more critical, higher-value functions that machines cannot replicate.

Some of the primary benefits of cobots in manufacturing are safety improvements, higher production efficiency, solutions to the skills gap and labor shortages, and more. Throughout the rest of this piece, we will explore the functions, uses and benefits of collaborative robots in even greater detail, to help you understand the potential benefits that they might provide for you.

What are collaborative robots?

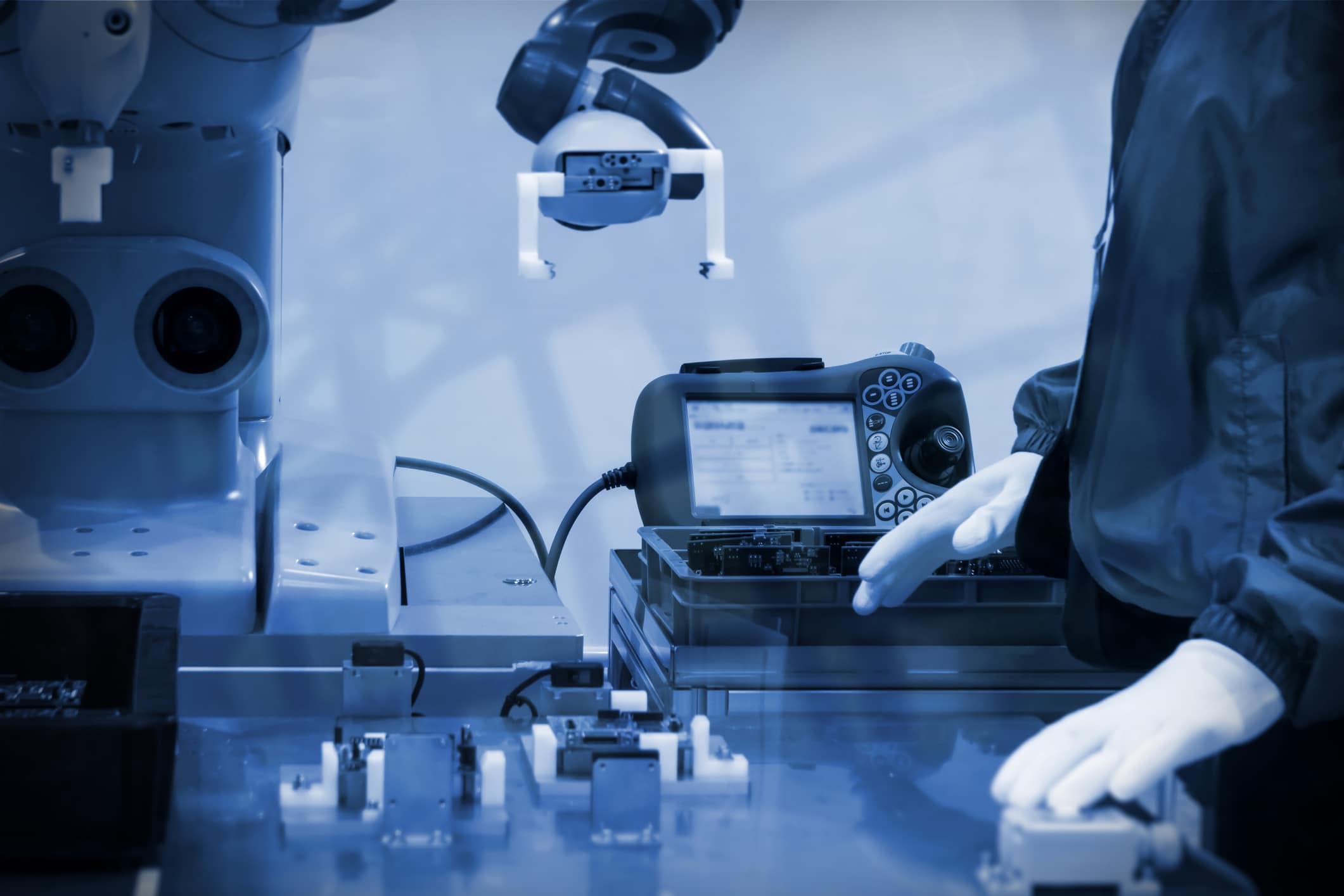

What is a cobot? A piece of equipment that can replicate tasks that might otherwise be carried out by an employee, but which are undesirable tasks to fulfill. In general, these are the tasks that are repetitive, unpleasant or hazardous — typically referred to as the “three D’s,” or dull, dirty and dangerous jobs. Cobots are designed with an articulated arm that can move along a set number of axes, or planes of motion — usually at least four axes, and up to six or seven. At the end of the arm, different tooling can be switched to complete different tasks, such as grabbing or placing, machining, welding, and more. The “collaborative” part of cobots comes from their ability to work directly in proximity with human workers.

Cobots can usually be set up and operated by nearly anyone, regardless of programming knowledge, and tasks can easily be configured and adjusted on the fly. The typical automation equipment of the past must usually be programmed by a technician and is completely isolated from employees, often with safety gates or fences. There is a high risk of injury if an employee contacts the legacy automation equipment, as well. Cobots, in contrast, are designed to operate right next to a human worker, with built-in sensors and failsafes, and a user-friendly operating interface.

What are cobots used for

Cobots have a broad range of uses due to their versatility, on account of their:

- Wide range of articulated motion

- Interchangeable tooling

- Easy setup

- Ability to work in close quarters with employees

For decades, automation has been solving the issue of completing repetitive tasks more quickly and efficiently. Cobots expand the potential of automation equipment into a wider range of tasks with greater efficiency, including machining, packaging and maintenance. In maintenance, for example, cobots can:

- Provide assistance in accessing dangerous or difficult-to-reach areas for diagnostics, repairs or component replacement

- Monitor equipment by reading and transmitting data, or sending alerts for further investigation

- Executing maintenance processes if equipment falls out of spec or fails, allowing technicians to be more efficient with their priorities and time

- Boost ROI by adding efficiency and speed to maintenance processes

Cobots can also hold pieces in place during welding, carry out machining tasks, remove finished parts from molds, pick and place pieces into packaging, move raw stock and finished pieces, stage products for QC, and much more.

Benefits of cobots

Cobots offer numerous benefits in maintenance and other areas, including:

- Increased human/robot efficiency: Cobot assistance, working in tandem with or in conjunction with human workers, adds speed, efficiency and accuracy to any task where it is applied — saving time and money.

- Accessibility for small and midsized manufacturers: As technology continues to develop, cobots are becoming ever-more affordable, even for smaller and mid-sized manufacturers looking to expand into more advanced and effective automation.

- Positive ROI: Cobots begin providing ROI almost immediately, with simple setup and configuration and versatility for nearly any process. The speed, efficiency and safety benefits of cobots can reduce your overall resource expenditures, usually providing positive ROI quickly.

- Improved flexibility: Cobots offer versatile, fluid motion across numerous axes, and can be easily reprogrammed for different tasks. This means that they can provide their benefits throughout the facility, not just in one area.

- Improved safety: By handling dangerous and repetitive tasks, cobots can take human workers out of harm’s way. They can help reduce the incidence of repetitive stress injuries — yielding worker safety benefits, improved morale, more uptime and lower costs.

- Unlimited potential: Cobots can truly be used in nearly any application that comes to mind — from maintenance to production to fulfillment and beyond.

With this understanding of how cobots operate and where they can be used, you now have the information needed to begin considering and investigating possible applications in your facility. As this technology becomes more and more affordable and widespread, it could help you maintain a competitive advantage while reducing costs and providing the best possible service and products for your customers. For industrial maintenance support, contact us today.