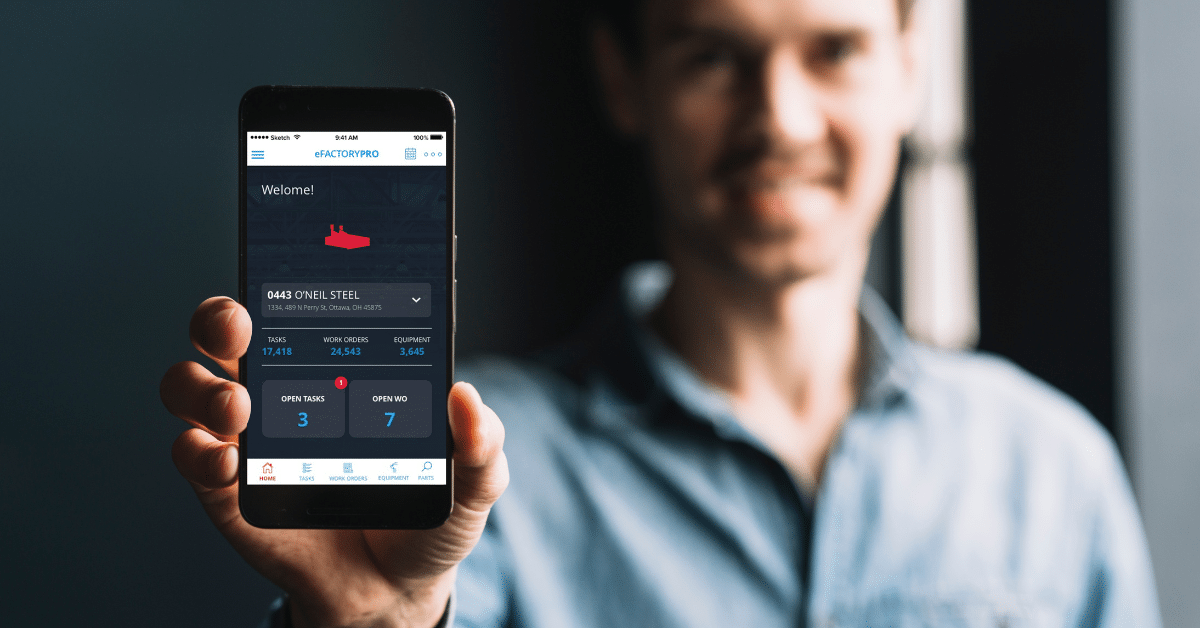

Maintenance is a critically important function of any industrial plant operation. As manufacturing technology – including maintenance technology – has continued to evolve, the potential benefits of a proactive maintenance strategy are greater than ever. One piece of advancing everyday consumer technology that overlaps with manufacturing is the pervasiveness of mobile devices and access. Smartphones have changed nearly every facet of our lives, including the way we do business. The manufacturing industry is no exception. Harnessing the power of this technology in a mobile maintenance strategy is essential to realizing the maximum benefits of maintenance today.

A successful mobile maintenance strategy comprises several tactics and practices. Depending on your industry and the processes you have in place, these may include:

- Mobile access to inventory data

- Mobile access to details about replacement parts

- Mobile monitoring of processes and performance

- Mobile control over machinery operations

Given the breadth of areas in which technology is changing manufacturing as a whole, implementations of these practices can differ greatly. Mobile implementations also depend on the other technology in use throughout the facility. However, having access to key plant and machine data at your fingertips has many advantages.

Key advantages

A mobile plant maintenance strategy can create several benefits for your operations in productivity, efficiency and the bottom line:

- Faster identification and location of repair parts – The easily accessible data mobile maintenance devices provide can make it easier for maintenance technicians to identify a required part, know whether it is in stock, and know where to find it – definitive solutions to maintenance issues can be identified and executed quickly, with less time consulting documentation and locating spares.

- More accurate inventory management and ordering – Mobile plant maintenance practices can combine with other technology to make it simpler to track spare part availability, enabling more accurate inventory management. This yields time and cost savings in reordering and prevents emergencies due to inaccurate counts.

- Access to real-time machinery metrics anytime, anywhere – The connected nature of today’s advanced manufacturing and maintenance technology means that performance data and metrics can be tracked from anywhere, with mobile alerts for any irregularities or risk factors. Beyond monitoring, this technology can also allow for remote control over processes, enabling action from anywhere within the facility or off-site.

- Native technology in which the next generation of workers is fluent – The younger generation of workers is already familiar with fulfilling tasks through mobile devices and applications. In addition to this built-in skill set, mobile maintenance can help present the manufacturing industry as a tech-savvy one, aiding in the elimination of the wide-stigma young people have about manufacturing that is directly contributing to the skills gap the industry is facing.

Mobile maintenance with ATS

Is a mobile maintenance strategy something you are considering implementing at your facility? If so, check out our How to Implement a Mobile Plant Maintenance Strategy: 5 Steps to Ensure Success guide! ATS offers industrial maintenance services to help improve productivity, reduce downtime, fulfill staffing needs, deliver process knowledge and boost the overall performance of your operations. As part of our comprehensive maintenance solution, we can help implement and operate a mobile plant maintenance strategy — allowing you to realize the benefits described above. To learn more, contact us today.