In many markets, customers seek product customization. Many consumer products are vulnerable to sudden changes in tastes and fashion — think clothing, or electronics or beverages — and elsewhere rapid technology changes can quickly make existing products obsolete.

These factors drive manufacturers to reconfigure production lines and re-engineer production processes. The problem is this is slow and expensive. What if demand shifts again before new manufacturing processes are fully implemented? Adaptive manufacturing appears to offer a solution.

What is adaptive manufacturing?

In a conventional manufacturing system, responding to new information and requirements is slow and expensive. Engineers need to formulate changes, update programs and modify tooling. In contrast, an adaptive system is one that responds quickly, with little or no human intervention, to imposed or required changes. Examples of such situations include:

- Materials coming from a different supplier

- New product sizes

- Revised product configurations

- Feedback regarding quality problems

- Changes in processing conditions

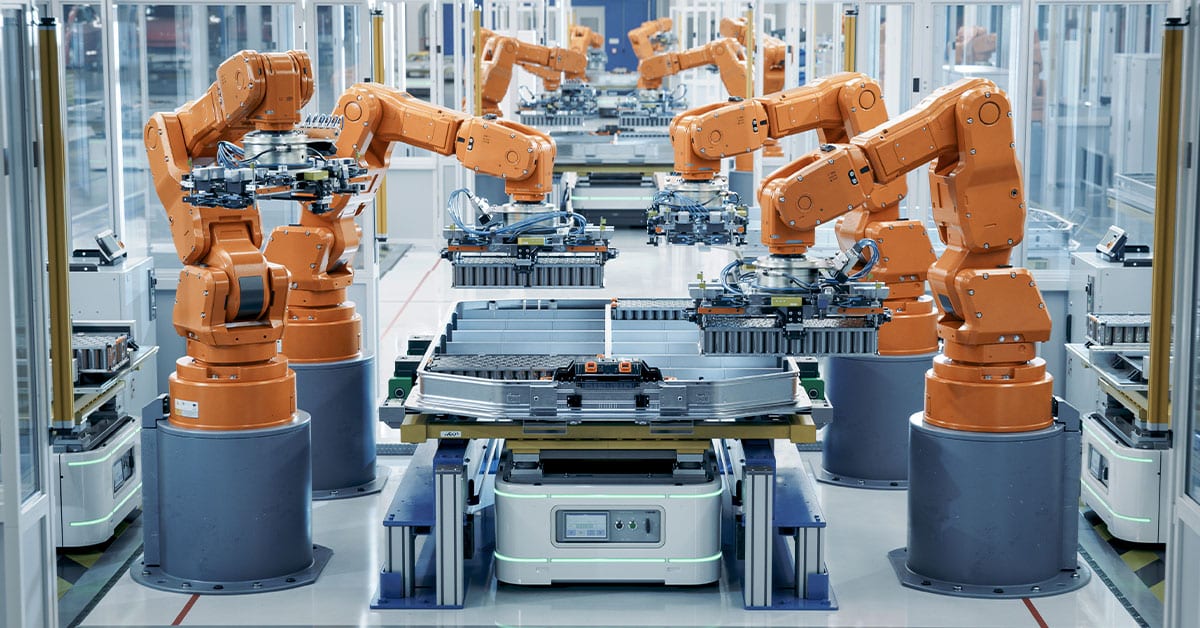

Adaptive manufacturing combines real-time data capture and IoT technologies with flexible robotics, advanced machine and process controls, automated quality control and modular manufacturing equipment.

Two essential elements of adaptive manufacturing are artificial intelligence (AI) and Industry 4.0 technologies. Industry 4.0 refers to the revolutionary impact of sensors, communications systems and advanced analytics that together provide new insights into ways of improving manufacturing. In parallel, AI in manufacturing makes sense of the volumes of data generated to identify and apply the changes in processing conditions needed.

Implementing adaptive manufacturing

By enabling a faster response, adaptive manufacturing technologies will let businesses improve operational efficiency in the face of constant change.

Adaptive thinking should also be applied to equipment maintenance, using Industry 4.0 technologies to identify ways of becoming more flexible and responsive. For example, a mix of corrective and adaptive maintenance strategies (blending breakdown with preventive maintenance) and switching between them in response to changing manufacturing conditions may provide an optimal solution.

The steps needed to implement adaptive manufacturing are:

- Assess current processes: What adaptive capabilities already exist, where will they have greatest impact and what technologies will be appropriate?

- Technology integration: Develop a plan for implementing the adaptive industrial solutions required — robotics, upgraded process controls, new sensors, modular machinery — along with the analytics tools needed. (A pilot approach is often a powerful way to sell the concept as well as to learn lessons that will support a wider implementation.)

- Skill development: Adaptive manufacturing solutions need higher levels of engineering and maintenance skills than the older conventional technologies. Develop and implement appropriate training programs.

- Data management: Real-time data from production assets provides actionable information. Such data-driven manufacturing is a way to improve product quality while raising OEE and efficiency. Identify the data that will be needed and how it will be gathered and used.

- Workflow redesign: When machinery has the ability to adapt to variations in product or packaging, changeovers become unnecessary. As part of the implementation, seek opportunities to streamline how orders are scheduled through the factory. The same applies to determining how and when maintenance should be performed.

- Partner/supplier collaboration: An adaptive manufacturing system should extend upstream to suppliers and downstream to customers. Implement portals that share data and requirements with both sets of stakeholders.

- Continuous improvement: Don’t expect implementation to be a “one and done” exercise. Instead, gather data that shows how well the system is performing, conduct regular reviews and find ways to make further improvements.

Benefits of adaptive manufacturing

The benefits of increasing adaptability in manufacturing processes extend throughout the enterprise. Notably, gains are seen in terms of:

- Increased flexibility: Gives production the ability to process a wider range of product without needing extended downtime for changeovers.

- Enhanced efficiency: With less time lost to changeovers, more time is available for production and OEE is higher. From a maintenance perspective, more data on processing equipment and conditions supports more effective preventive maintenance and adoption of predictive maintenance.

- Improved product quality: Adaptive technology provides the ability to fine-tune processing conditions in response to short-term variations. Examples include adjusting furnace temperatures and/or speed to account for the differences in product mass and changing drying times as humidity varies.

- Customization capabilities: Greater flexibility means more ability to customize individual products, increasing attractiveness to customers and potentially winning more business.

- Cost reduction: More consistent product quality, combined with less time spent on changeovers and less unplanned downtime, results in significant cost savings.

- Faster time to market: When equipment can adapt to new product sizes and features and change package formats, many of the tooling delays that slow new product introduction are eliminated.

Advice on the latest maintenance trends

An emerging concept, adaptive manufacturing harnesses Industry 4.0 technologies, along with robotics, AI and the use of modular equipment, for a step change in flexibility. An adaptive manufacturing system can handle a wide range of products, performing customization and process optimization to reduce costs and maximize efficiency while better meeting customer expectations.

As a leader in outsourced industrial maintenance, ATS assesses developments such as adaptive manufacturing to offer industrial businesses the best possible advice. Services include, but are not limited to, short-term support, machine health monitoring and storeroom management. Contact us to learn more.