Key benefits

Asset productivity

Improve asset performance through optimized MRO inventory management, root cause analysis and best-in-class part repairs.

Improved uptime

Increased efficiencies in parts management translates into greater production output and a longer lifespan for your equipment.

Cost reduction

Our AI-powered industrial asset management software drives maintenance and operational efficiencies that eliminate manufacturing waste while improving your bottom line.

A holistic approach to industrial MRO & reliability

Manufacturers face constant roadblocks when trying to implement and execute a successful industrial asset management program. Hundreds of vendor relationships, disorganized inventory systems, localized or niche repair houses and buy-it-now parts urgency can lead to inefficiency and unnecessary costs.

These common, yet undervalued situations can have a significant impact on operational efficiency. That’s why many leading manufacturing organizations count on ATS for a variety of MRO solutions and services including: storeroom management, repairable parts management, root cause analysis, slow-moving and obsolete inventory reduction, intra-site logistics and hard-to-find parts sourcing.

Storeroom management

Optimize your inventory and transform your storeroom into a well-organized, efficient hub with our proven on-site parts management program. We implement best practices and leading technology to improve inventory accuracy, reduce spending and ensure long-term operational continuity.

- Data entry & collection

- Core retrieval

- Storeroom personnel

- Monthly reporting

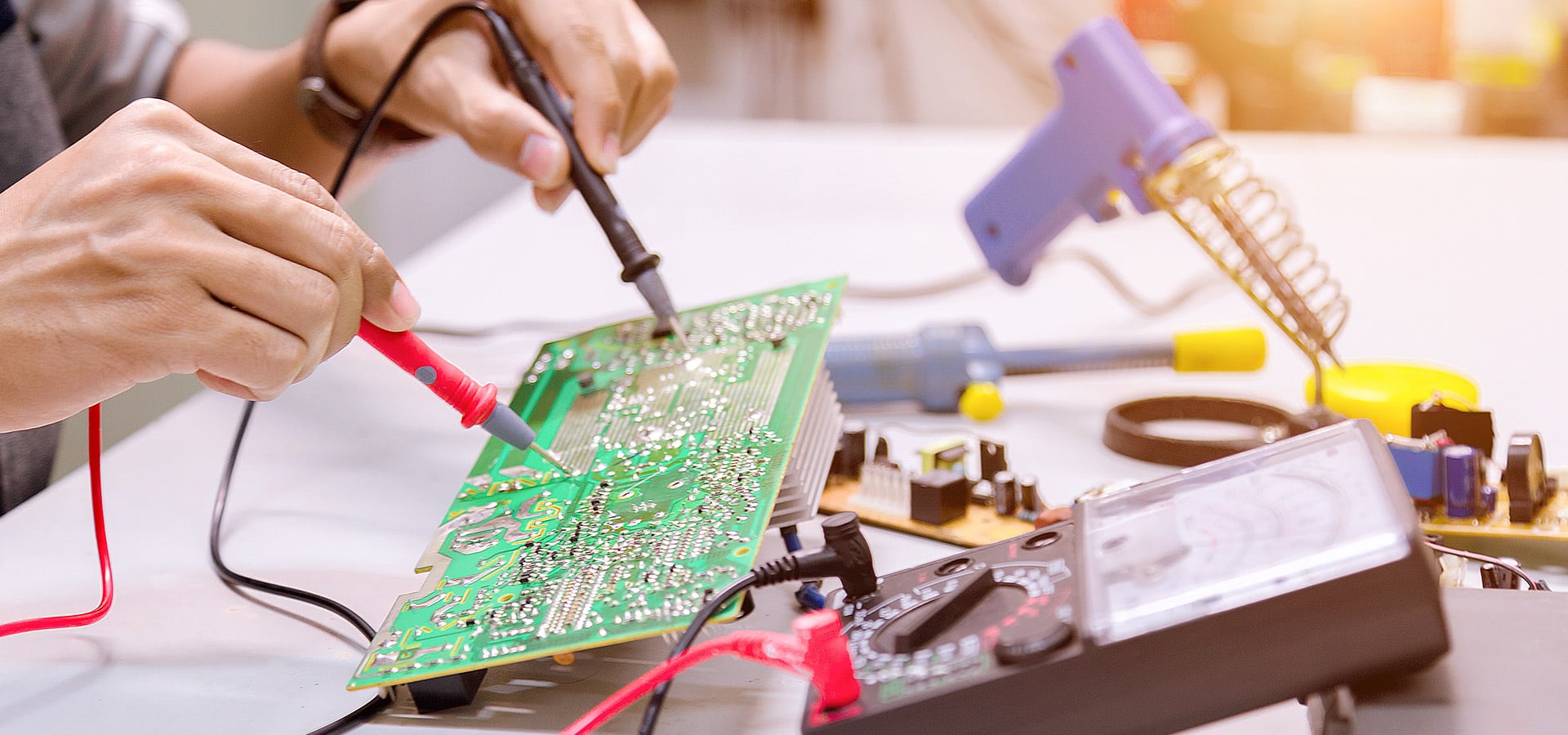

Repairable parts management

Enhance reliability with a data-driven, on-site repairable parts management program, built to continually improve the reliability of industrial components and assets.

- Competitive repair pricing

- End-to-end management tracking

- Root cause failure analysis

- Strategic sourcing of obsolete parts

Parts services

Streamline your part and supply needs—repair, surplus and new—all supported by our state-of-the-art service center that helps get your equipment back up and running.

- 40-60% cost savings vs. buying new

- Rapid turnaround within two weeks

- 60% reduction in repetitive failures

- 1-year in service, 5-year shelf warranty

Maximize your equipment’s potential with our AI-powered MRO program

/

TRUSTED BY leading manufacTURERS

Explore industrial MRO resources

Learn how we take MRO maintenance to a new level as an all-in-one provider for improved asset reliability.

Brochure

Info Sheet

Info Sheet

Leading MRO asset management provider

Our comprehensive asset management services provide equipment expertise across process and discrete manufacturing, delivering results to many business functions across organizations.