Turning Bottlenecks into Bottling Success

Wine manufacturer boosts production availability from 33% to 68%

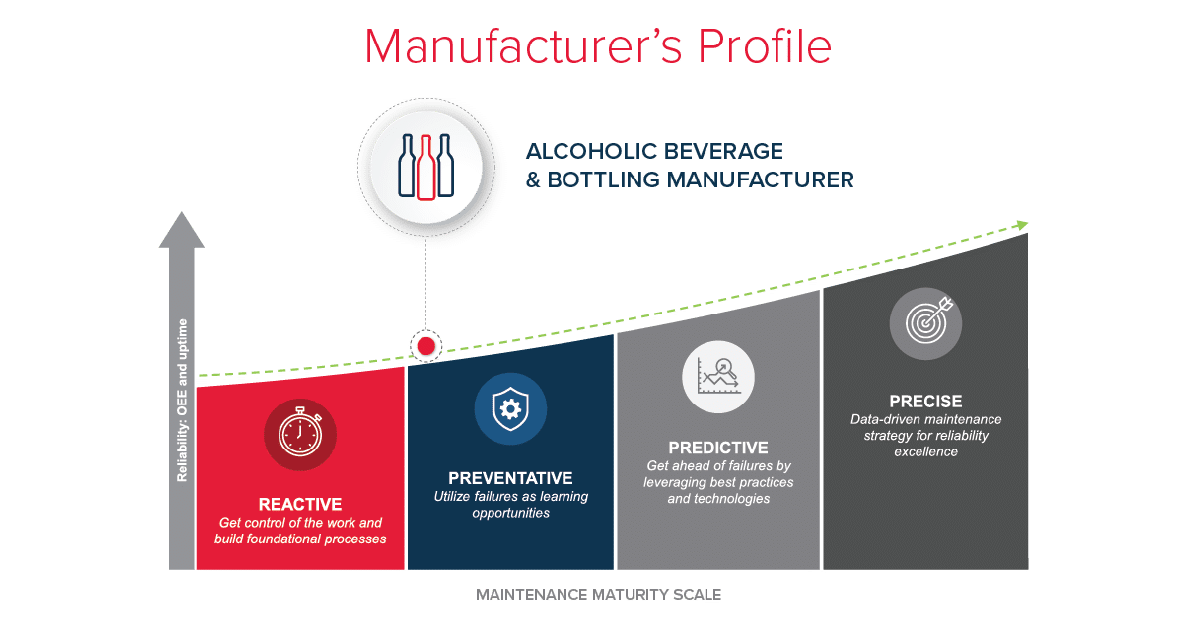

Plant improvement opportunities

A Napa Valley wine manufacturer encountered significant operational challenges due to a shortage of skilled maintenance personnel. This led to reduced productivity, delayed maintenance and missed production targets. Safety concerns also grew as incident rates remained high. Further complicating these issues, ongoing production backlogs limited the ability to perform essential preventative maintenance tasks.

To address these problems, the company partnered with us and launched a short-term maintenance program. This collaboration quickly delivered results, with major improvements seen within the first 60 days.

Success within 60 days

To quickly overcome critical maintenance and parts challenges, eight expert multi-craft technicians were deployed on-site. By addressing the maintenance and spare parts challenges, asset performance improved maximizing production uptime at the Napa Valley facility.

-

Improved safety

& LOTO proceduresLOTO (Lockout-Tagout) procedures isolate energy sources during maintenance, ensuring worker safety.

-

Enhanced cross-functional collaboration

Optimizing maintenance strategies, leading to downtime reduction, improved productivity and successful projects.

-

Production availability increased from 33% to 68%

High production availability enhanced output, ensured on-time deliveries, and reduced cost—strengthening competitiveness and profitability.

Ready to improve productivity at your facility?

Growth and partnership

Building on the success of the short-term maintenance program, the manufacturer chose to expand their partnership with ATS by transitioning to a comprehensive maintenance solution. The comprehensive maintenance program is a long-term, turnkey solution designed to optimize performance and reliability, while driving cost savings. Key program features include:

Leadership & technical workforce

Multi-craft technicians, skilled maintenance leadership and experienced engineers

Work execution management

Consistent and reliable service quality that improves communication and culture

R360® Machine Health Monitoring

The latest predictive technologies to boost factory maintenance, technician and production efficiency

R360® Technology Center

Access to condition monitoring expertise and tools to proactively manage machine health

eFactory Pro CMMS and business intelligence

Advanced technology to streamline planning, tracking and optimizing maintenance activities

SkillPoint™ technical training

Ongoing internal training in advanced CNC/PLC, electronic, mechanical, robotics and more