Each year, factories waste millions of dollars by concluding that new industrial parts are a prerequisite for trouble-free operation. But is replacing parts instead of repairing them really the most cost-effective option?

Data has shown, in parts repair vs. replacement cost analysis, that repaired or re-engineered components can save 50% versus the cost of buying new. It’s natural for us to crave new things. From the latest gossip, to recent health trends, to the most up-to-date gadgets, new is nearly always perceived to be better. New is also perceived to be expedient—and when factory equipment malfunctions, it can seem faster and less bothersome to simply replace a worn part instead of repairing it. But parts replacement may not be the right decision for your business.

Replacing parts comes with a range of hidden costs that can add up without you being aware of them. These can include expedited shipping to resolve emergency outages, extended lead times for obsolete components, scrapping parts that could be repairable or steep learning curves for new models or controls. Replacement is sometimes the right choice—such as meeting safety standards or modernizing outdated technology—but in many cases, a well-executed repair offers greater value and keeps operations running reliably.

Choosing to repair your industrial components can lead to longer asset life, a better understanding of equipment failure modes and stronger predictive maintenance programs. Here are a few reasons repairing your industrial parts might be a long-term cost-saver for your maintenance operations.

Repair vs. replace cost analysis

When considering to repair or replace for your maintenance needs, be sure to weigh the following factors to determine the most advantageous course of action.

- Consider the warranty period of the part: If a part is still within its warranty period, then the most cost-effective decision will be whichever is covered under the warranty, repair or replacement. If a part is out of warranty—or even if it is nearing the end of its warranty period—then you should take the cost analysis factors below into consideration as well. Why does it matter if a part is within warranty, but nearing the end of the period? Parts that have failed once are more likely to fail again. If the warranty only covers repairs, and is almost up, you may want to consider replacement instead.

- Get quotes for the price of the repair vs. replacement: If the repair cost is greater than the cost of replacement, then there is no benefit to proceeding with the repair, and the part should be replaced. Additionally, if the cost of maintenance is 60% or more of the cost of a replacement part, purchasing a new part should be considered. Be sure to factor in the hidden costs of replacements, such as installation, reprogramming, re-commissioning or the need to keep spares in stock.

- Consider asset lifecycle management: A plant lifecycle management strategy takes a holistic, long-term view of the facility, as well as the parts and processes within it, including maintenance strategies and decisions. An asset lifecycle management plan may offer additional guidance for repair or replace decisions based on maintenance and ordering schedules, budgets, operating procedures and other factors.

- Consider downtime: How long your equipment will be down has a significant impact on your bottom line. Replacing parts vs. repairing them in-place may be the key to keeping downtime as minimal as possible, so think about your timeframe before making a decision. This is where having a good source for CMMS/EAM data can be especially helpful.

- Prioritize safety: Equipment that breaks down frequently due to wear and tear represents a greater risk to employee safety. Any components that are critical to safety or compliance should be considered for a replacement-only policy to ensure you don’t have to worry about them.

A simple framework for repair vs. replace decisions

Without a strong flowchart, you’ll approach each replacement-or-repair decision starting from zero every time. Here’s a quick overview of a typical framework outlining factors to consider when replacing a component vs. repairing it:

- Safety and Compliance: Is the part safety-critical or regulated? If so, you should lean toward OEM or new parts unless a certified repair exists.

- Cost: Is the repair less than 50% to 60% of the price of a new part including downtime and logistics?

- Downtime: Which option will get the equipment back online sooner?

- Lifecycle: Is the asset nearing its end-of-life, or is it due for an upgrade?

- Data and Reliability: Has this part failed repeatedly, and do you have root-cause insights?

- Sustainability: Will repairing the part help you reach your ESG targets without adding risk?

Using CMMS/EAM can be a big help in standardizing the data you need to make these decisions.

Repairing parts can help predictive maintenance work better

Roughly 20% of plant operating expenses are maintenance-related. Repairing parts rather than replacing them is ultimately about more than just getting back to normal. It’s also an opportunity to diagnose larger issues that can be mitigated to help keep costs under control.

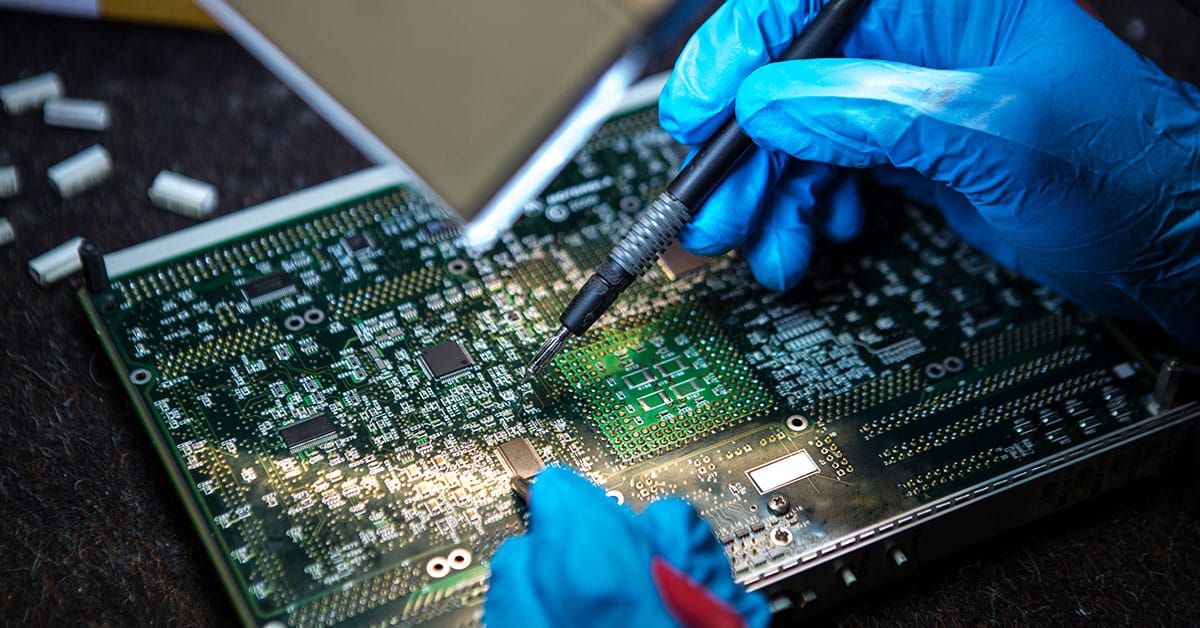

For example, an electronic cabinet may fail. Replacing the cabinet would restore functionality, but it wouldn’t necessarily mean the underlying issues that caused the failure would be addressed. Performing a root cause analysis could determine that a chip was exposed to excessive heat and moisture, which could indicate that a gasket seal was the failure point. A proper repair protocol would include replacing the chip that caused the failure of the board, followed by replacement of the cabinet seal so adverse conditions don’t cause similar problems in the future. This gives maintenance teams the knowledge they need to approach similar failures in the future, which they may not receive through a full replacement.

Evolving standards in parts repair can support a move from reactive to predictive maintenance practices; updated technologies and root cause analysis techniques can measure equipment health in real time, with the repair process using such instruments to determine why something failed and how to predict future failure in other parts. “Replace with new” is a reactive strategy; repairing, by contrast, can reveal issues that support predictive maintenance approaches, not only making compliance easier but also causing factories to run more efficiently through improved design. Repair isn’t always the right choice—but when supported by thorough analysis and corrective actions, it often becomes the smarter, more cost-effective solution.

Collecting parts repair data supports critical decisions in your manufacturing environment

Recording all kinds of metrics, including mean time between failure (MTBF), mean time to repair (MTTR), warranty tracking, inventory turns, last price paid and more, is critical. The discipline supports good manufacturing practices by documenting performance and identifying problems before they occur. And from a maintenance standpoint, if the same part fails multiple times in the same place or across similar units, data is available to determine the cause. There is a story behind every failed component. Don’t let that story get away in the scrap bin when choosing to repair or replace parts. Make sure this information is being tracked in your CMMS and repair reports, so you always know what your assets are trying to tell you. Capturing this data means you can feed it into spare-part criticality analysis, capital planning and replacement roadmaps, and vendor performance reviews.

Repairing parts helps drive sustainability & green manufacturing practices

Choosing parts repair over replacement can help manufacturers meet sustainability and green manufacturing goals, while also saving money over the long run. How?

- Part repair reduces the need for production of brand-new parts.

- Repair also eliminates the need for transportation of new parts, vastly reducing the carbon footprint of a replacement.

- The repair and maintenance process may include reused or reclaimed components and materials that may have otherwise been scrapped, saving them from the landfill.

- Tracking the percentage of parts that are repaired rather than replaced can feature as a key metric in ESG reporting. .

Repairable parts management is more effective with parts repair

The best maintenance programs involve both transactional and Repairable Parts Management (RPM) options. Transactional services (such as our own Parts Repair offerings) provide offsite repair along with failure reports, reverse engineering, commercial calibration, warranties and more. RPM is a more robust onsite solution that captures more information and helps ensure the fastest turnaround time. When administered by a full-time team, it also includes industrial asset management, preventive maintenance programs, and process improvement efforts. All of these combined ensures that you’re getting the best value for your money. There will always be an appeal—and yes, sometimes an advantage—to fast, easy replacement of worn-out parts with new. The real point, however, is to determine not what is expedient, but what is most beneficial to the business.

When replacement is the better option

Even though repair brings numerous benefits over replacement, it’s not always the best choice. There are certain situations in which replacement should be seriously considered, including:

- When the quotes for repair routinely represent more than 60% of the cost of a new component.

- If failures reoccur frequently despite repairs and other corrective actions.

- In cases where obsolete equipment and technology limit performance, safety or the availability of new parts.

- When newer models would provide significant gains in terms of efficiency or reliability.

From a capital planning perspective, a failed component could be the catalyst for accelerating an upgrade that is already justified. This is why it’s important to approach each new failure as its own incident and not try to apply a blanket policy to repairing or replacing the faulty component.

By taking a more informed approach to parts management, manufacturers can improve the performance of not just a single asset, but the entire operation. At ATS, we support that effort with trusted parts repair services, strategic storeroom management, and proven reliability improvements that help keep production running smoothly.

Our commitment to dependable service includes an industry‑leading warranty program that provides 1‑year in‑service coverage and a 5‑year shelf warranty, giving you confidence that repaired parts will perform when you need them most. It’s one more way we help reduce risk, extend part life and support long‑term operational stability.

For deeper guidance on when to repair or replace your factory parts, explore our whitepaper. Or contact with us directly—we’re here to help you address your parts challenges and keep your factory running better.