Notable productivity improvements

Due to rising costs, some mills are being forced to downsize, outsource, revamp paper production equipment, purchase modern equipment to replace aging machines, or use materials produced elsewhere to make finished products. Downsizing and outsourcing, especially in this age of increasing retirements, means a loss of in-house knowledge. To meet these challenges, mill managers seek paper and pulp industry maintenance solutions that optimize asset performance and keep equipment online for as long as possible.

Our expertise in the equipment used in pulp and paper mill maintenance allows us to help your factory overcome operational challenges while increasing uptime and optimizing productivity. Our knowledge of your equipment includes, but is not limited to:

Pulpers

Digesters

Refiners

Paper Machines

Fine Paper Machines

Paperboard Machines

Converting and Packaging Lines

Powerhouse Boilers

“At the end of Q3 during the third year, our plant had equaled its entire output for the previous year.”– Production Manager, Leading Paper & Pulp Manufacturer

Reliability excellence and beyond

Our skilled workforce, established processes and data-driven technologies help you meet your unique business needs. Whether you’re facing a skills gap or productivity challenges, we can deploy mill preventive maintenance and predictive maintenance solutions, such as CMMS, IIoT sensors, and our Reliability 360® Machine Health Monitoring solution, to optimize plant efficiency and performance.

- Recruitment and retention

- Skilled, technical workforce

- IIoT technologies

- World-class safety

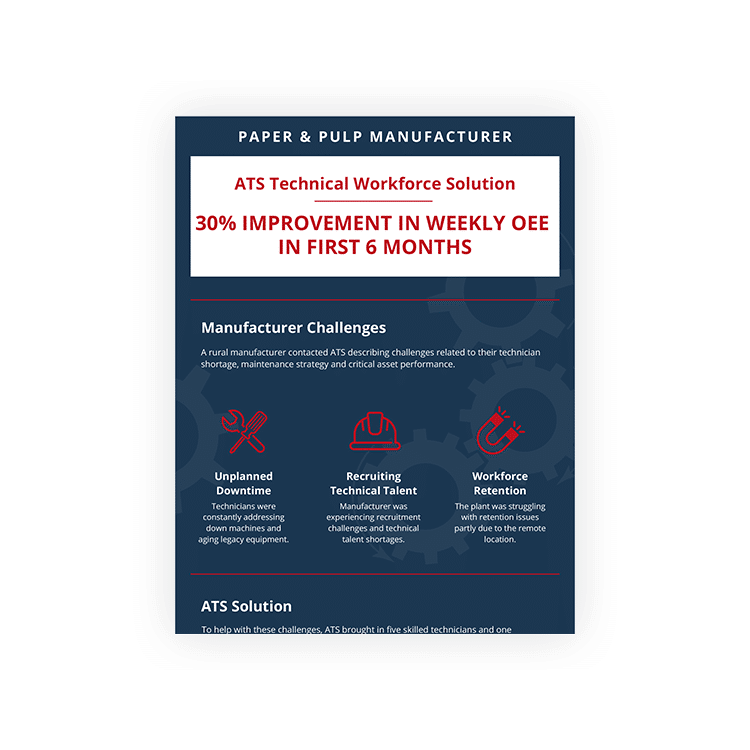

30% improvement in weekly OEE

A paper and pulp manufacturer struggled to recruit and retain technical talent. With the help of ATS, the manufacturer experienced significant improvements in OEE and work order completions.

“Having my technicians paired with ATS technicians raised their skill levels and helped them learn more through on-the-job training.”

Lead with a safety mindset

A safe workplace starts with a commitment to safety culture. ATS technicians bring best-in-class safety procedures to your site, helping you prioritize employee well-being while reducing recordable incidents, costly repairs and unplanned downtime.

-

World-class safety

Our Beyond Zero safety culture prioritizes compliance and employee well-being

-

Low incident rates

ATS has a 50% lower recordable incident rate than industry average

-

Exceed OSHA standards

ATS has an industry-leading OSHA incident rate and regulatory compliance

Overcome asset challenges with our expertise

Shutdowns due to aging and obsolete equipment threaten reliability and performance, but because your machines are expensive, you make every effort to keep them operational. Let us help with paper and pulp mill maintenance services, parts sourcing and repairs, and skilled technicians who deliver quality service. Whether you’re maintaining legacy systems or upgrading to modern solutions, our blend of workforce expertise and technology-driven maintenance delivers the results you need.

Paper & pulp industrial plant maintenance solutions

Our services and skills help eliminate unplanned downtime and ensure that your equipment operates at peak performance. Our proactive paper machinery maintenance, repair services, parts sourcing, smart technology and skills training help you improve asset performance and achieve production goals. We can scale our services to meet short-term needs or form a long-term partnership.