Industrial robots have long been associated with efficiency and productivity, but historically, they could only operate in rigid, structured environments. Traditional industrial robots excelled at repetitive tasks yet lacked adaptability. Today, with the integration of artificial intelligence in manufacturing, these machines are becoming smarter, more flexible and essential to the rise of smart factories.

This transformation matters because manufacturers are facing pressures unlike ever before. Labor shortages, the need for product customization, tighter production schedules and global supply chain volatility are driving demand for automation. By embedding machine learning in robotics, manufacturers are finding ways to overcome traditional limitations like inflexible programming and excessive downtime.

AI enables robots to learn from data, sense their environment and make real-time decisions. These abilities allow manufacturers to move away from rigid systems and toward agile, AI-driven manufacturing solutions that improve precision and reduce costs. For many businesses, this isn’t only about automation, but building a resilient, future-ready operation that can adapt quickly to new challenges.

The evolution of robotics in manufacturing

Industrial robotics has advanced significantly since the first robot was used in a diecasting operation in 1959. That early innovation demonstrated how robots could take on “3D” jobs — those that are dirty, dangerous and difficult.

By the late 1960s and 70s, manufacturers began using five- and six-axis electrically powered robots, capable of more complex movements and controlled by sophisticated kinematics. Soon after, specialized robots like cartesian robots (x, y, z movement) and scara robots (ideal for high-speed assembly and pick-and-place tasks) entered production lines.

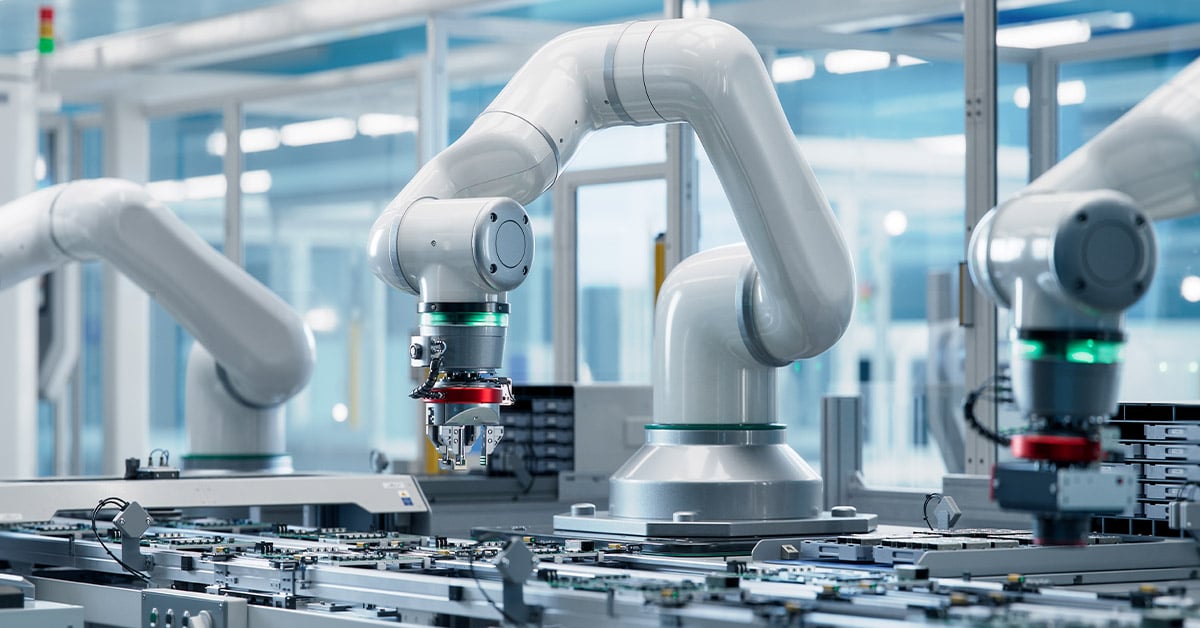

The most recent milestone has been the development of the collaborative robot — or “cobot.” Unlike traditional robots, cobots are designed to work safely alongside human workers. Built-in safety features such as power and force limits, stop-state monitoring and speed separation reduce the need for costly safety cages. This breakthrough expanded robotics’ reach into environments where flexibility and human-machine collaboration are critical.

Collaborative robots in manufacturing are engineered with safety systems that prevent them from injuring anyone within its work envelope. This can be done by:

- Monitoring and controlling speed and separation

- Stop-state monitoring

- Limits on power and force

- Hand guiding

Cobots still require risk assessments before being put into service, because the tool or gripper could be doing something potentially hazardous. In most applications though, they need far less guarding than conventional robots. Eliminating the need for large and expensive safety cells, which in term mandate complex systems for moving work in and out of the cell, is one of their biggest benefits.

How AI-powered robots are improving manufacturing

The shift to Industry 4.0 has created a landscape where digital twin technology, robotic process automation and predictive analytics are redefining what factories can achieve. Despite the success of automation, traditional robots still required structured setups and exhaustive programming.

In this world of “smart” factories, opportunities for artificial intelligence in manufacturing are only just starting to emerge, but robotics appears to be one of the most impactful:

- Reduced setup and programming time → lowering costs and enabling shorter production runs.

- Improved adaptability → robots can adjust to part variations, reducing errors and downtime.

- Expanded applications → enabling robots to tackle complex assembly, material handling and inspection tasks previously impossible to automate.

- Smarter integration → AI helps robots coordinate with PLCs, sensors and systems across production lines.

No longer need the work environment be highly structured: Instead, the robot, aided by cameras and other sensors, can find its way around. Four ways in which this improves manufacturing are:

- Enables shorter production runs (because setup and programming time is reduced)

- Reduces implementation cost and complexity

- Enables new applications previously not feasible for robotic automation

- Reduces cell downtime due to teach pendant programming

These capabilities are especially critical as manufacturers balance speed with quality and efficiency. For production managers under pressure to hit deadlines, AI-powered robotics allows quick scaling without sacrificing quality.

Ways manufacturing robots utilize AI

The ability to learn and adapt to changes in the environment requires the robot to sense what’s going on in its work envelope. This is done mainly with cameras, although scanners and 3D sensors are also used. AI tools then analyze the images or other signals acquired and use this to determine what the robot should do.

AI is applied to industrial robots for three types of application:

- Environment perception using sensors & tactile feedback: This could be to detect the presence of part trays or pallets of material, sense loads or adapt to changes in the friction of surfaces being touched or picked up.

- Data-driven computation and execution: Path planning is a major challenge in many robot applications, especially when approach angle and direction affect how the process is performed or part design precludes some tool/gripper orientations. Rather than a programmer spending a lot of time attempting to find the best route, and likely still not achieving the optimal solution, AI can quickly evaluate alternatives and determine the best path. For example, an articulated robot can determine the best angle to mesh gears or insert components.

- Integration into automated systems: Robot cells use multiple sensors to detect presence, position, orientation and other parameters, all of which must be handled by the cell PLC and robot controller. Despite this, a robot will still sometimes fail to grasp or place a part, simply because it’s not exactly where it was expected. A robot powered by AI has the ability to recognize variation, in the cell, workpiece or tool, and adjust accordingly.

By embedding intelligence into manufacturing robots, companies are unlocking new capabilities across assembly, inspection and logistics.

Examples of manufacturing robotics & artificial intelligence

While robots and increasingly cobots are staples of industrial automation, examples of robotics in artificial intelligence are still in short supply. However, work in academia, and some pioneering industrial applications, suggest at least four classes of application.

- Cobots: The new generation of industrial robot companies design them to work alongside and even in cooperation with human operators. Adding AI to the mix enhances the ability of the cobot to work with a human. For example, in assembly, it can wait until the human has completed a complex task like insertion before adding the next component.

- Industrial assembly: Orientation and fit have so far proven difficult aspects of assembly work to automate. However, AI gives robots greatly enhanced capabilities to judge position and orientation, enabling performance of complex tasks like meshing gears. Assessing quality of fit is another area where human judgment has been needed. With AI though, a robot can acquire information about how tight or loose an assembly feels through attached sensors, and either change parts or make adjustments as needed.

- Piece picking: Grasping and retrieving randomly oriented and overlapping parts from a bin is one of the hardest problems in robotics. AI will let a robotic system learn the most effective picking strategies for particular sizes, shapes, weights and even textures of parts, thereby increasing picking speed and reliability.

- Inspection: A robot carrying a camera can scan over a part to look for flaws such as scratches, chips and dents. Should suspected flaws be detected, the robot can move the camera closer and change orientation to obtain views from different positions before making a final good/no good decision. AI-enabled robots ensure consistency for quality control in manufacturing.

How has robotics changed manufacturing technology?

The manufacturing industry has always relied on tools that bring speed and accuracy. Robotics elevated this by automating machine tending, palletizing, welding and assembly. Yet, adoption was once limited to high-volume operations because of complexity and cost.

Today, advanced robotics systems combined with AI lower barriers for smaller manufacturers. Flexible programming, lower guarding requirements and adaptability make robotics practical for companies with diverse product lines. This democratization means even SMEs can integrate robotics in production lines, gaining advantages that were once reserved for large enterprises.

The industrial robotics market is expected to grow significantly in the next decade, driven by AI, edge computing and demand for resilience.

Current applications and future outlook

Manufacturers evaluating robotics often ask:

- Can robots handle unstructured environments?

- What types of companies benefit most from AI-driven robotics?

- Where is the technology headed in the next decade?

Applications today

AI-powered industrial manufacturing robots are now used across:

- Electronics assembly → handling delicate components with high precision.

- Automotive plants → combining cobots and articulated robots for mixed-model production.

- Logistics and supply chain automation → using mobile robots to move materials autonomously.

- Additive manufacturing → integrating robotic arms with 3D printing for complex part builds.

Universal robots, known for their plug-and-play flexibility, are particularly popular among SMEs, where agility and ROI are top concerns.

Future outlook

The future of robotic automation points toward:

- Unstructured environment navigation: AI allows robots to adapt to changing layouts or unexpected obstacles.

- Self-monitoring systems: Robots will increasingly diagnose their own performance, flagging maintenance issues before downtime occurs

- Human-robot collaboration: Expect deeper synergy where robots offload repetitive tasks, allowing the human worker to focus on creativity, oversight and problem-solving.

- Smart factory innovations: AI will enable fully connected ecosystems, where robots, IoT devices and digital twins in production optimize flow in real time.

From aerospace to consumer goods, the winners will be those who adopt early and scale quickly.

Maintenance services for busy manufacturers

Over the years industrial robots have proven extremely reliable. Their complete cells are complex though and can need a range of maintenance services. Experienced professionals in industrial automation and advanced robotics can provide the support needed to keep these systems running efficiently.