From Trial to Global Transformation

Reliability 360® Machine Health Monitoring drives $2M in avoided losses

Real results, real impact

Unplanned downtime avoided in first 30 days of trial

Sensors installed across 20+ plants after trial

Estimated avoided losses in the first year

When reactive maintenance falls short

Faced with increasing production demands and ongoing supply chain challenges, a global packaging manufacturer needed to rethink how to monitor the health of its critical equipment. Traditional, reactive maintenance was no longer sustainable, as it led to costly downtime, prolonged operational disruptions, safety risks, and reduced asset lifespan.

After looking at nearly a dozen asset monitoring sensor solutions, the manufacturer partnered with ATS for a 60-day R360® Machine Health Monitoring trial to:

Trialing predictive maintenance

To address reliability challenges at two of the manufacturer’s facilities, we deployed Reliability 360® Machine Health Monitoring—first at their can manufacturing plant, then at their glass bottle facility. Sensors were installed on critical equipment, feeding real-time data into cloud dashboards supported by automated alerts and expert insights.

This empowered their maintenance teams to respond proactively, reducing downtime and preventing costly failures. The solution proved to be more than just a monitoring tool—it delivered scalable, actionable intelligence that directly impacted operations.

How it works

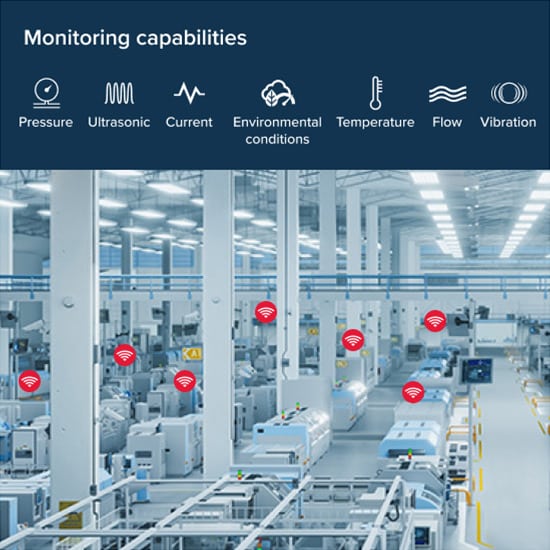

Comprehensive equipment monitoring

Monitor critical assets 24/7 with 22+ sensor types, feeding real-time data to the dashboard.

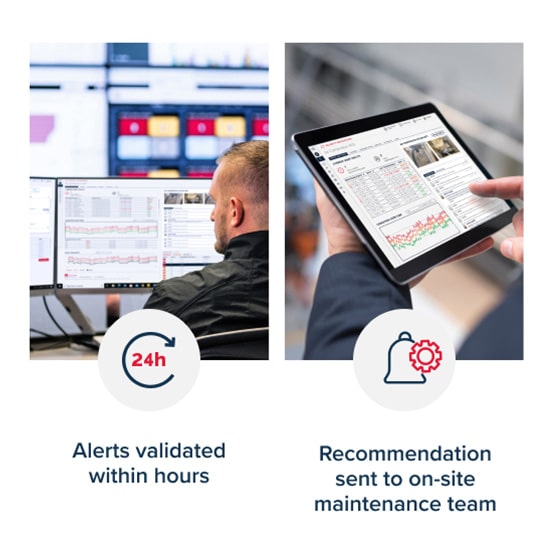

Expert data analysis

Condition monitoring experts analyze every alert and send detailed recommendations to the on-site maintenance team.

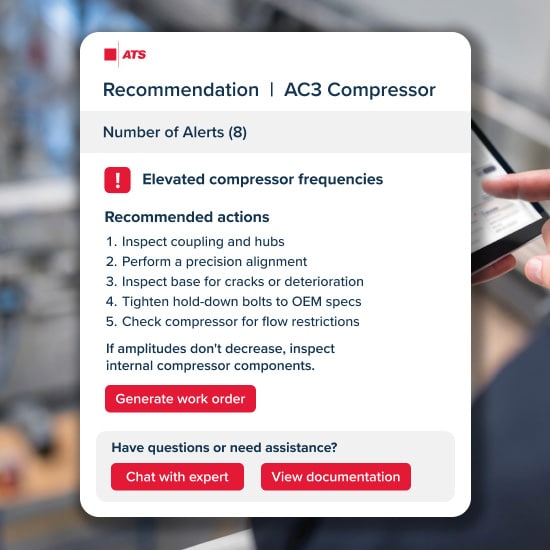

Detailed recommendations, streamlined workflow

Recommendations and alert data are sent to the dashboard or your CMMS, where maintenance teams can consult ATS experts using built-in tools before heading to the floor.

Single source for maintenance and reliability

Rely on our expert maintenance and part repair support if needed to quickly address potential failures and aid your on-site team.

Ongoing managed service

Each customer is supported by a condition monitoring expert and dedicated success team, with ongoing engagement focused on daily operations and long-term value beyond go-live.

Trial results

Plant | Trial period | Costs avoided |

Can manufacturing | First 30 days | $86,000 |

Glass bottle manufacturing | First 60 days | $100,000 |

Ready to improve uptime at your facility?

Enterprise-wide expansion

Following the success at the can and glass bottle manufacturing plants, the packaging manufacturer chose ATS as its long-term reliability partner—expanding Reliability 360® Machine Health Monitoring to all 20+ manufacturing sites across the U.S.

In the first year of enterprise-wide deployment:

- 490 issues detected

- 50 downtime risks resolved

- $2 million estimated in downtime avoided

“We use the sensors not only to catch assets before failure, but also to adjust our maintenance plans.”