Our people-driven culture

At ATS, our culture is a way of life that ties into everything we do. Rooted in continuous improvement and focused on a future driven by technology, we have a contagious determination to take our company and our customers to the next level of innovation and growth.

Live safety 24/7

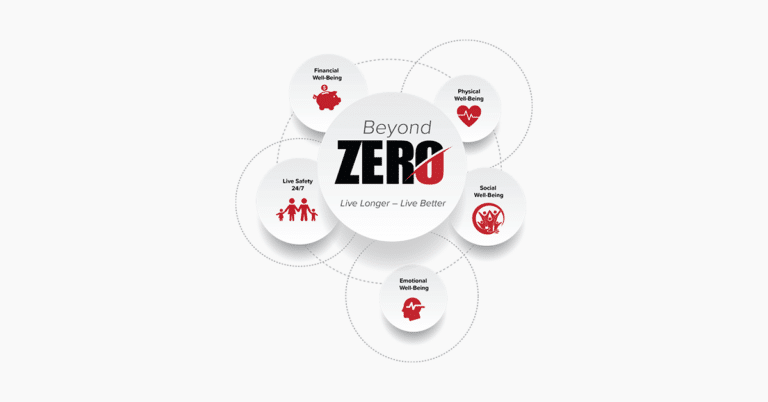

Safety isn’t just a priority—it’s a foundational part of our culture. Through our Beyond Zero program, we put this value into action by partnering with maintenance teams to proactively reduce incidents, enhance well-being and foster a culture of continuous improvement.

Beyond Zero goes further than zero incidents—it’s about creating an environment where employees feel supported, protected and empowered—both on and off the job.

-

World-class safety

Our Beyond Zero safety culture prioritizes compliance and employee well-being

-

Low incident rates

On average, we maintain a 50% lower recordable incident rate than industry standard

-

Exceed OSHA standards

ATS has an industry-leading OSHA incident rate and regulatory compliance

“One thing I can promise is ATS’ commitment to a strong safety culture and our employees’ well-being will never waver, and our journey for continuous improvement will never end.”– Jeff Owens, CEO

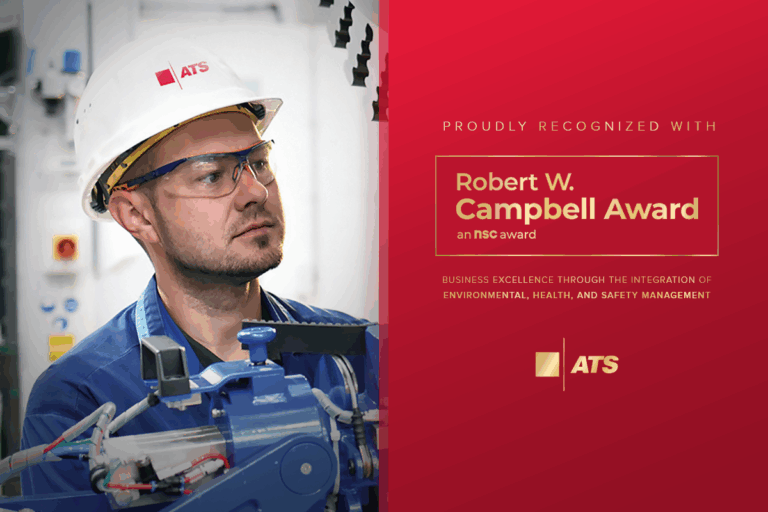

The gold standard in safety excellence

To better manage the environmental, health, and safety (EHS) challenges inherent in manufacturing, we have an established, top-down cultural commitment to safety excellence. With a proven track record, you can trust us to improve and positively impact your plant safety.

We are proud to be awarded the prestigious Robert W. Campbell Award by the National Safety Council (NSC), America’s leading nonprofit safety advocate.

“ATS’s ‘Beyond Zero’ multi-faceted approach to employee wellbeing is a fantastic case study on how even organizations with a well-established safety culture can continue to refine their safety practices to drive positive results for their workers and their bottom line.”

Developing the workforce of tomorrow

Finding qualified technical talent is a growing challenge across manufacturing. We address this challenge through ongoing training and certification, a network of subject matter experts, and a strategic recruiting approach that ensures our people have the capabilities to meet your specific needs. With over 75,000 training hours delivered annually, we keep skills sharp and teams ready—any shift, any day—so your operations run smoothly.

Join Our Mailing List

Sign up with your email to receive the latest updates

Frequently asked questions

What makes ATS safety excellence different?

Safety is our number one cultural commitment, and our entire team from the top down is committed to our Beyond Zero program that prioritizes safety and overall well-being. Beyond Zero is a proactive commitment that goes beyond aiming for zero incidents; it drives continuous improvement and fosters a culture of holistic care, ensuring our people feel supported, protected, and empowered—both on and off the job.

What certifications do your technicians have?

Our team always assesses the requirements of each facility and will certify our technicians based on the environment. 60% of ATS site leadership has been certified by the Board of Certified Safety Professionals (BCSP) as Safety Trained Supervisors (STS). The remaining 40% are currently studying to take the certification exam. Recognizing our dedication to excellence in the safety, health, and environmental profession as a Diamond Certification Champion, BCSP produced this video recognizing our long-standing commitment to creating a safer workplace by championing professional credentialing.

Have you won any awards for safety?

Yes, the National Safety Council awarded ATS with the prestigious Robert W. Campbell award that recognizes leading companies that have attained business excellence through the integration of environment, health, and safety.

Internally, we have a President’s Award for Safety Excellence that team sites work toward each year. Our CEO, Jeff Owens, has also been recognized by the National Safety Council as a top “CEO Who Gets It” for going above and beyond to protect employees through risk reduction, performance measurement, safety management solutions and leadership and employee engagement.

Additionally, we consistently maintain a recordable incident rate that is 50% lower than the industry standard.

How does ATS ensure I get the right technicians with the right skills?

Before any ATS technician arrives at your plant, they are evaluated through a technical skills assessment to baseline their current skillsets. Then, we tailor the curriculum to develop their skillset along with additional mentorship to ensure they’re ready to support your plant’s specific equipment. With decades of training experience and technical expertise, we know how to carefully craft a plan to get the right technicians with the right skills to make your factory run better.

Will ATS technicians integrate with our existing maintenance team?

Our technicians are trained not just on equipment but also in communication and collaboration. This means these skilled workers can fit right into your operations and serve as seamless extensions of your current team, following your processes and priorities while also bringing a wealth of additional technical support and knowledge.

Resources

Learn more about our cultural commitments and the full range of maintenance solutions we offer.

About us

Through innovation, a proven maintenance framework and a diverse team, we grew from an idea on a napkin to the technology-driven leader we are today.

Careers

Committed to the success of our team members, we provide a work experience that’s focused on you. Explore our job openings, our culture guide and everything ATS has to offer.