Safety increases

Leak detection services prevent potential harm caused by dangerous gases

Reliability improves

Regular checks can reveal if pressurized systems are operating beyond acceptable limits

Technology utilization

Ultrasound leak detection equipment finds issues too high pitched for humans to hear

Protect equipment

Suitable for compressed air systems, steam traps, gas lines, vacuum equipment and more

Energy efficiency

Timely leak detection prevents significant wasting of compressed air and electricity

No downtime required

Equipment can be inspected while it runs, minimizing disruption

Without detection, leaks can lead to larger issues

Even the smallest leaks can mean a drop in pressure that indicates that larger operational issues are lurking on the horizon, including increased cycle times, energy demand and undue stress on compressors. Leaking air also leads to the loss of equipment efficiency, which can result in the need for emergency repairs and unplanned downtime, costly maintenance and lowered productivity. According to recent research, it is estimated that anywhere between 20-30% of compressed air ends up being wasted due to unidentified leaks. A tiny leak at less than 100 psi still has the potential to cost a business thousands of dollars in energy loss if left unaddressed.

Our ultrasonic leak detection services offer many benefits. You’ll enjoy lower energy costs, improved safety, more reliable air and gas delivery, more uptime and increased maintenance cost savings. No more manual leak checks, no more documenting air and gas leaks and completing maintenance tickets, we help you become more efficient in maintenance prioritization, so you can spend less time on expensive repairs and more time on production. Our ultrasonic leak testing capabilities also help you comply with relevant environmental and safety regulations.

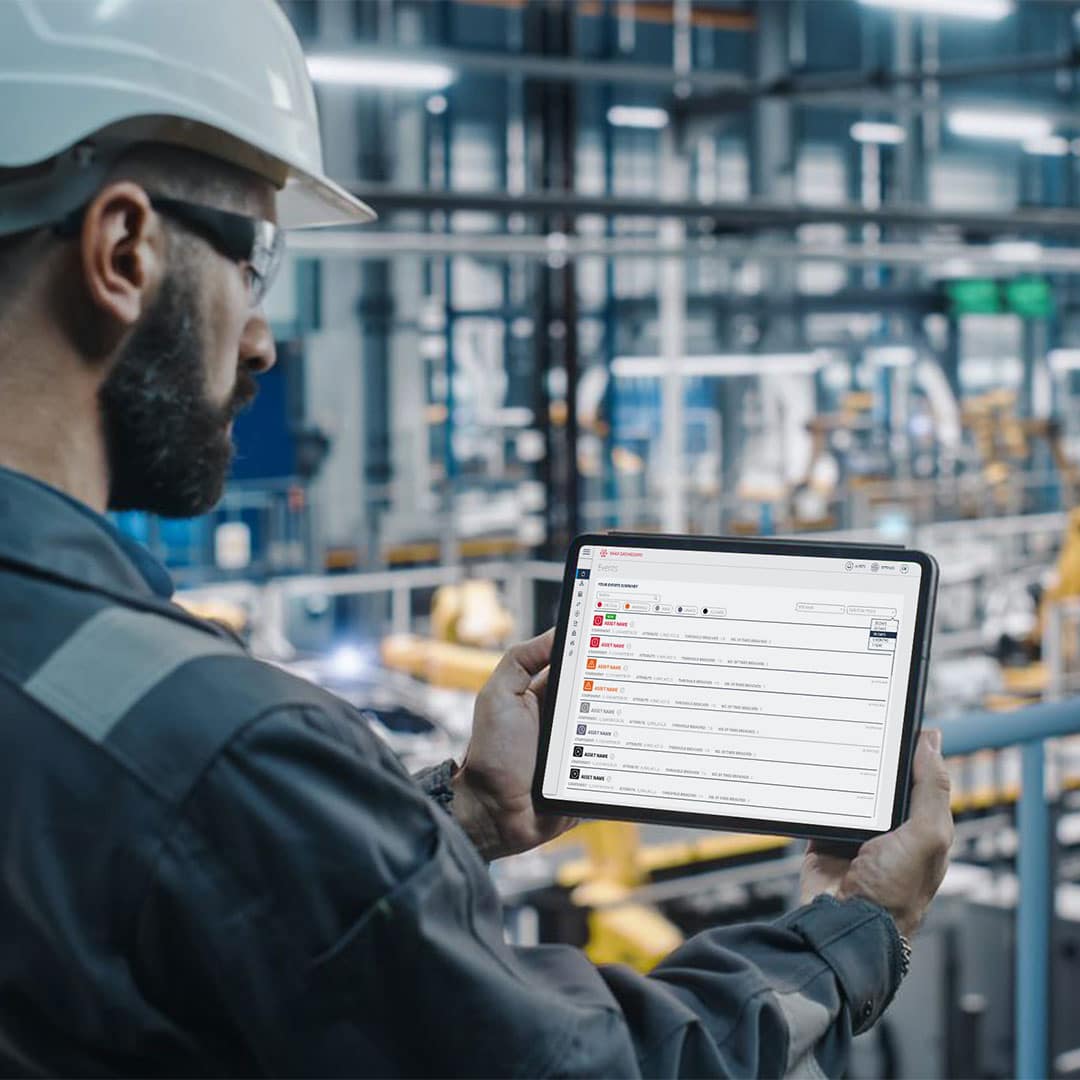

End-to-end IIoT solution

We leverage over four decades of maintenance and reliability experience paired with the latest predictive maintenance technologies to prevent unplanned downtime.

- Consultation & installation

- 24/7 condition monitoring

- Predictive maintenance sensors

- Real-time alerts

- Prescriptive actions

- Measurable results

- Optional maintenance & parts support

Detect and prioritize compressed air leaks with ATS’ IIoT-enabled monitoring. Our sensors integrate with your CMMS or digital dashboards to deliver real-time alerts, actionable insights, and ongoing system visibility—enabling you to make smarter maintenance decisions.

Get more time, energy and cost-savings back

Ultrasonic leak detection resources

Learn more about ultrasonic leak testing and the role of sensor technology in predictive maintenance. Our ultrasonic leak detectors use advanced sensors to locate leaks.

Ultrasonic leak detection FAQs

What’s the difference between ultrasonic and traditional leak detection?

Ultrasonic leak detection uses high-frequency sound to find gas and air leaks that are too small for traditional visual or soap tests to detect.

Can equipment be tested while it’s running?

Yes, this process and the ultrasonic detectors used are non-invasive and can be performed during operation with no downtime required.

How often should ultrasonic leak detection be performed?

Typically scans should be performed at least annually, but high-use systems may benefit from semi-annual scans. Our ultrasonic leak detector sensors enable continuous, real-time monitoring that ensures nothing is left to chance.

Compressed air leak detection services for manufacturers

With over four decades of experience and highly skilled technicians, ATS is perfectly positioned to provide early gas leak detection services for a wide range of applications in your air, gas and vacuum lines. We offer trained technicians, nationwide coverage and full PdM integration to help you remain as efficient and compliant as possible. Let us help you protect your facility, your personnel and your productivity.