Visual inspection

Routine oil checks can reveal the presence of contaminants, such as water and other debris

Fluid property inspection

A chemical test indicates if the right oil and additives are being used and any degradation

Wear analysis

Focuses on the debris in the oil and indicates if the equipment is damaged or close to failure

Machinery oil analysis for predictive maintenance

Lubrication fluid analysis involves the monitoring and inspection of machinery oil to determine its condition and ascertain whether maintenance is required. Utilizing ATS technician expertise, our predictive oil analysis involves taking a small oil sample while the machine is running, examining the data and continuously monitoring for condition trends of both fluid and machine.

The results of our oil condition analysis allow you to detect unexpected equipment wear, get a clear idea of when oil needs replacing, gain insight into your equipment performance, and make well-informed decisions when scheduling lubricant maintenance. Let us help you improve your machine efficiency and productivity, while lowering your maintenance costs.

IIoT-driven oil monitoring solution

We leverage over four decades of maintenance and reliability experience paired with the latest predictive maintenance technologies to prevent unplanned downtime.

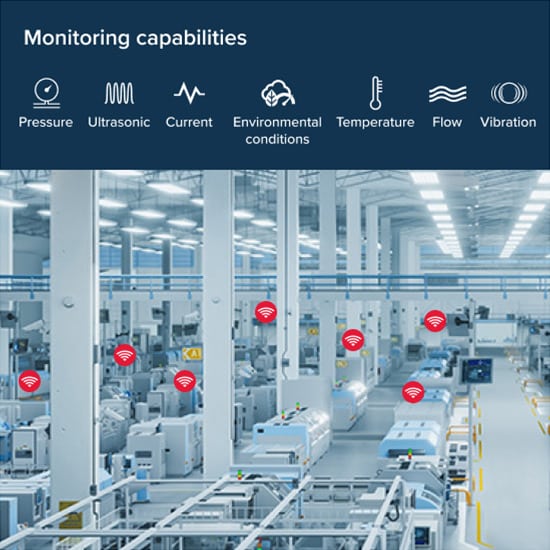

Comprehensive equipment monitoring

Monitor critical assets 24/7 with 22+ sensor types, feeding real-time data to the dashboard.

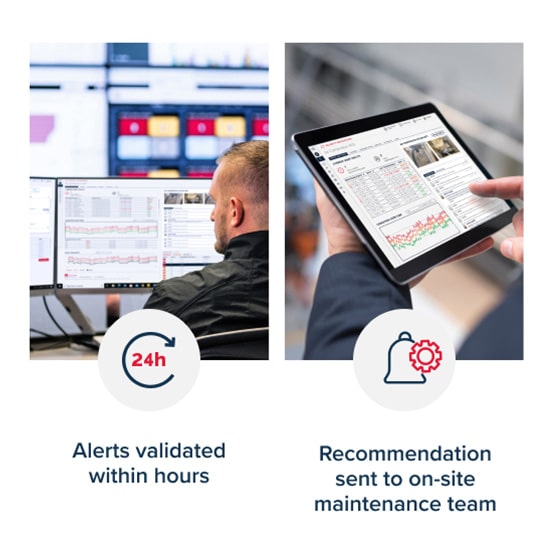

Expert data analysis

Condition monitoring experts analyze every alert and send detailed recommendations to the on-site maintenance team.

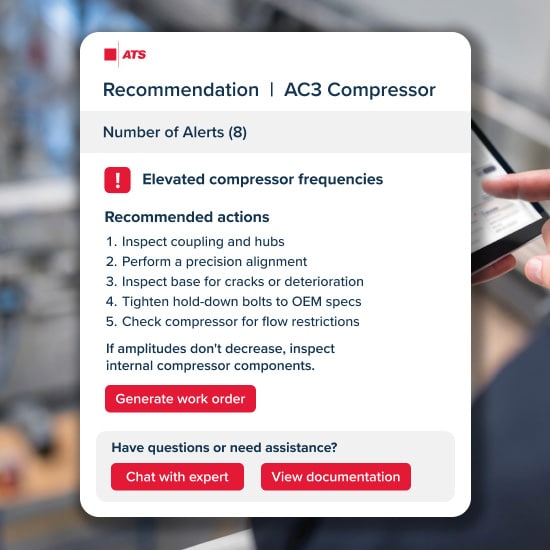

Detailed recommendations, streamlined workflow

Recommendations and alert data are sent to the dashboard or your CMMS, where maintenance teams can consult ATS experts using built-in tools before heading to the floor.

Single source for maintenance and reliability

Rely on our expert maintenance and part repair support if needed to quickly address potential failures and aid your on-site team.

Ongoing managed service

Each customer is supported by a condition monitoring expert and dedicated success team, with ongoing engagement focused on daily operations and long-term value beyond go-live.

Improve overall equipment performance

Oil analytics resources

Learn how we can help you better manage your lubricating oil maintenance program.

Oil analysis for manufacturers

Making our lubricant analysis service an important part of your comprehensive equipment maintenance strategy helps keep your machinery running longer and improves productivity. We’re primed and ready to help manufacturing sectors with high-precision machinery keep their assets healthy and performing as expected. With our help, manufacturers can ensure the safety and compliance of their machinery, as well.

Frequently asked questions about oil analysis services

How often should oil be analyzed?

The frequency of testing services depends on the criticality of the machinery and its typical operating conditions. Our experts can help you get a handle on the ideal schedule for your assets.

Can this service be combined with other predictive maintenance tools?

Absolutely — ATS can bundle these services with other predictive maintenance capabilities including vibration monitoring and thermal imaging for a comprehensive industrial maintenance program.