Reliability 360® Machine Health Monitoring

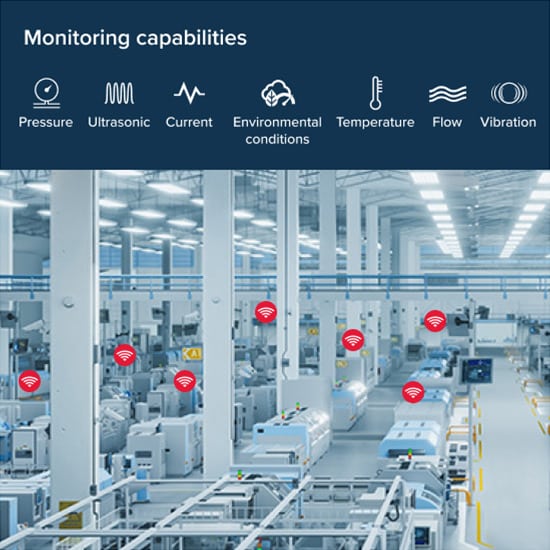

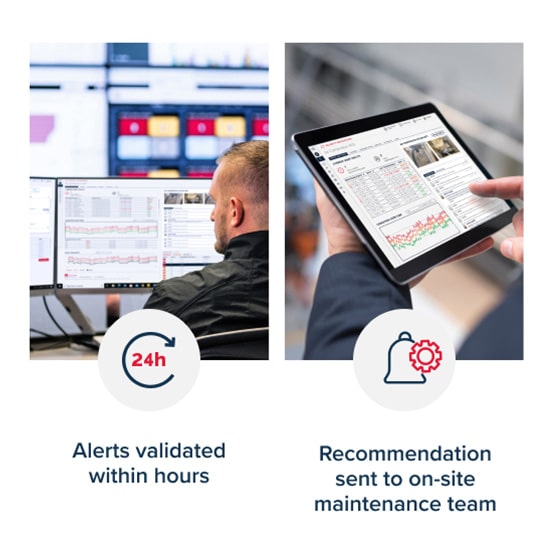

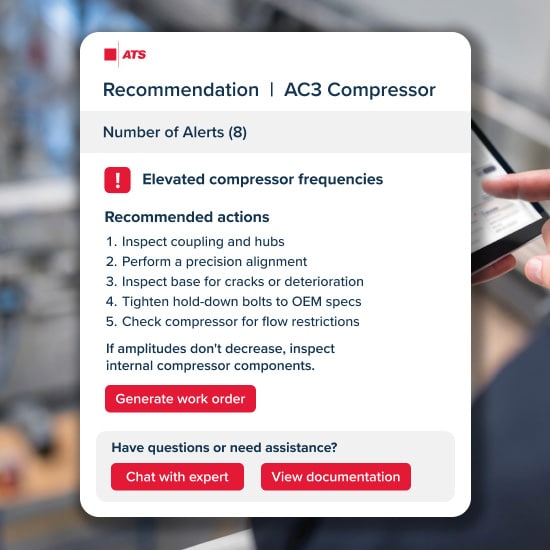

Sensor technology is becoming standard in industrial operations, but gathering data is just the beginning. The real challenge lies in interpreting the data and applying corrective maintenance actions that drive results. Without that, even the most advanced machine monitoring solutions fall short, unable to bridge the gap between failure detection and prevention.

Reliability 360® Machine Health Monitoring offers industry-leading predictive maintenance. The result? Fewer breakdowns, fewer disruptions, and smarter use of maintenance resources. Designed for flexibility and built for scale, it supports everything from targeted site-level deployments to unified, enterprise-wide reliability strategies.