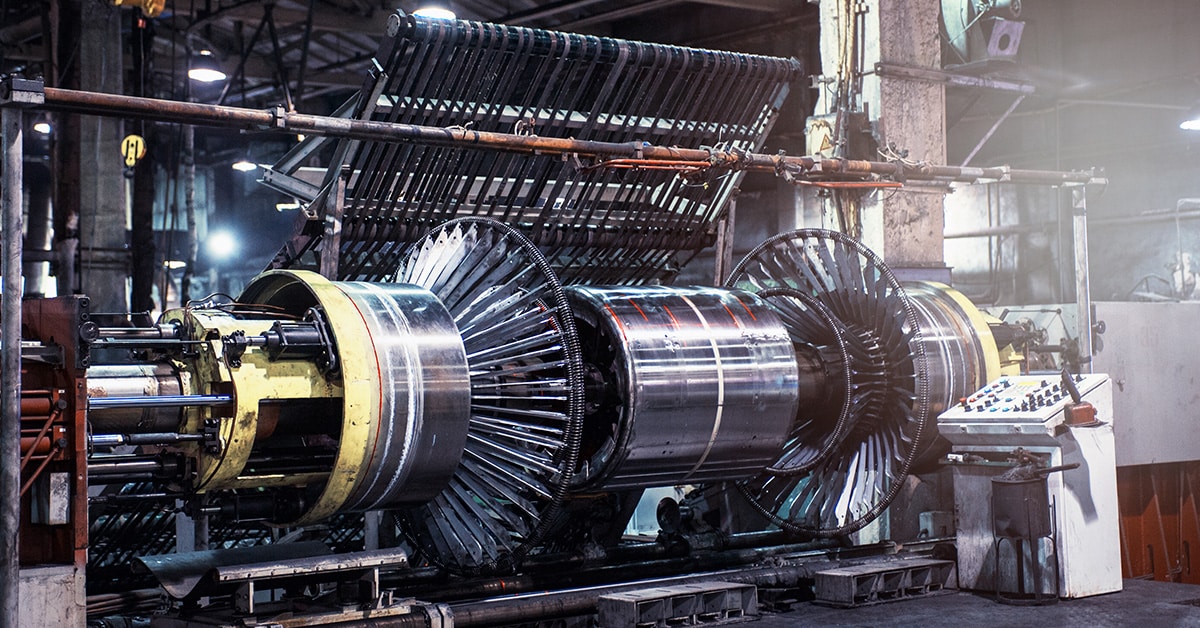

Every robot, press, lathe and conveyor used in a factory is a fixed asset, as are other similar types of equipment. These assets enable production and directly support customer demand. Effective maintenance ensures that these assets produce quality product at the expected output rate. It also extends their life and minimizes their cost, thus maximizing the return the business gets from its investment.

Most manufacturers rely on a computerized maintenance management system (CMMS) to optimize maintenance effectiveness. However, CMMS addresses only part of the process, whereas fixed asset management takes a broader view.

Fixed asset management covers activities such as purchasing, utilization, disposal and depreciation, and it links with the company’s financial and health and safety systems for regulatory compliance.

Effective fixed asset management improves operational efficiency and helps the business remain competitive. This article explains how modern maintenance practices support asset lifetime management and fixed asset management processes.

What counts as a fixed asset in manufacturing?

Accounting groups assets into categories such as current and fixed, and further distinguishes between tangible and intangible. A tangible asset is a physical item you can see and touch—examples include a sack of raw material or a robot. Unlike those physical assets, intangible assets such as patents, trademarks, copyrights, software and licenses can’t be touched but still hold significant value.

Current assets are those that will be used quickly, like raw material inventory and consumables. Fixed assets are those that will have a useful life of more than a year. They typically need maintenance throughout their lifecycle to ensure that they continue to operate safely and reliably.

In accounting terms, fixed assets are classified as “Property, Plant, & Equipment” (PP&E). For manufacturing businesses, “Property” refers to land and related assets, such as buildings. The “Plant” is the building in which manufacturing takes place, plus those services integrated into the building. Compressed air services, HVAC and lighting are examples.

“Equipment” covers everything used for production, from casting, molding, mixing and forming machines to conveyors, robots and packaging systems. Also within this group are higher value, longer-lasting tools, such as molds, dies and stamping tools. Lower value items, especially those with a relatively short life, are usually considered consumables.

Components of a fixed asset management program

The starting point is a register of all the fixed assets the business owns. This asset register should give every item a unique identification and log where it can be found. Purchase records are often tied to the register entries, along with the acquisition cost, depreciation and current asset value. Most programs will also include leased equipment, although this is handled in a slightly different way, as depreciation is not considered.

This link to accounting records means asset registers are usually maintained by the Accounting function. Other aspects of fixed asset management are handled by Maintenance, Manufacturing Engineering, and the Environmental, Health and Safety function.

Maintenance ensures that fixed assets are ready to operate. This is done through the CMMS, which often forms part of the fixed asset management system. The CMMS is used to schedule maintenance and maintain maintenance history. This includes capturing reliability, availability and maintainability data which, as well as being valuable for performance measurement, is used for assessing when replacement is needed.

Increasingly, the CMMS is also linked to machine condition monitoring systems. These gather data on performance and status and can enable predictive maintenance analytics that reduce maintenance costs and machine downtime.

Manufacturing Engineering is often involved during equipment purchasing, for major upgrades and rebuilds, and, to a lesser extent, during disposal. Again, all these transactions are logged within the system, and the data gathered is a core element of specification development, planning and selection.

Safety and regulatory compliance issues are also usually tied to the fixed asset management process. Equipment such as cranes and pressure vessels need regular inspection and certification, and other environmental factors can also be included.

Fixed asset management and reliability maintenance

Fixed assets are intended to produce revenue. If those tools don’t work as expected, revenue will be lost. While everything in the PP&E category influences revenue, and also the flipside, costs, it’s the plant and equipment aspects that can have the biggest effect. Unplanned downtime can be very disruptive, because it almost inevitably disrupts manufacturing operations.

Unplanned downtime often stems from ineffective maintenance practices. It can lead to slow production rates and increased quality waste. Even brief microstoppages—those quick fixes that only take seconds—disrupt workflow, reduce morale and may post safety risks.

Two other impacts of not doing required maintenance are reduced equipment life and increased operating and capital expenses.

Integrating the asset register with the CMMS improves visibility across areas the maintenance team covers. This improves responsiveness and effectiveness, and supports better work order traceability and access to maintenance histories. Linkages to replacement parts and service materials also help improve MRO asset management and support mean time to repair (MTTR) reduction efforts.

Results include more informed decisions regarding equipment replacement, better parts availability, reduced parts inventory and, ultimately, improved mean time between failure (MTBF) metrics. In multisite businesses, an asset register-CMMS connection also helps standardize decision-making across sites.

Technology driving fixed asset management

In a large plant, effective asset lifecycle management is a complex undertaking. New technologies helping with increased data availability, faster updates and better planning are:

- Latest-generation CMMS products: These generate digital work orders, often in response to input from predictive maintenance analytics and condition monitoring systems. They also perform PM scheduling and automate and even analyze asset history.

- IIoT sensor technology: These measure parameters such as real-time vibration, temperature and pressure, and either send the data directly to a machine health system or perform some processing before sending summaries or exception reports. This avoids having to send a technician to take readings, saving time while improving data density and reliability.

- Digital twins: These virtual representations of industrial equipment faithfully reflect the physical production reality. They enable simulation for predictive intervention, thus avoiding breakdowns, and can support technician training without delaying production operations.

- Barcode/RFID systems: These simplify asset tracking by enabling registry tracking and updates through mobile equipment. They also provide linkage directly to information such as parts list and maintenance histories, helping increase technician effectiveness at the machine.

These technologies dramatically increase data accuracy and availability. This helps shift asset management decisions from being reactive to increasingly predictive. It also supports asset performance optimization efforts and improvements in asset utilization.

The benefits of fixed asset management

A carefully developed, thoughtfully implemented asset management system yields measurable operational, financial and strategic benefits.

Operational benefits

- Increased machine uptime and asset availability: Maintenance schedules are optimized more effectively, and the move toward predictive maintenance reduces the total amount of work needed.

- OEE improvement: Improved maintenance effectiveness means machines suffer less downtime, run closer to target speed and generate fewer nonconforming products.

- Reduced emergency repair costs: Greater ability to predict and plan for maintenance, plus increased MRO management effectiveness, lower the frequency of emergency repairs and the need to arrange rush deliveries of spares.

Financial benefits

- Reduced total cost of ownership (TCO): Lower repair costs can be realized due to better maintenance, less disruption due to unplanned downtime, and extended asset life.

- Accurate cost allocation by asset: The asset register and CMMS together ensure every cost associated with a piece of equipment is recorded correctly. This ensures the costs attributable to each item are better captured and understood.

- Extended equipment life: This reduces capital expenditures needed for equipment replacement, freeing resources for strategic projects such as increased automation and new production lines. Continuing to operate fully depreciated equipment—when it remains safe and reliable—can further lower overall costs.

- Optimized insurance and compliance spending: Logging inspection and certification dates, along with maintenance records, helps ensure that equipment stays compliant. It also helps ensure accurate valuation of records and supports better safety, both of which can benefit insurance premiums.

Strategic benefits

- Better planning for expansion and modernization: Data on usage, reliability and maintainability improves understanding of risks and supports detailed planning.

- Asset risk transparency for corporate decision-makers: Improved visibility into the status and performance of equipment enables more informed decision-making.

The 5 stages of a fixed asset lifecycle

A mature fixed asset program supports more effective maintenance management throughout the lifecycle of every asset and avoids falling back on run-to-failure strategies. Understanding this lifecycle and its effect on asset value is key to effective long-term planning as well as total cost reduction.

The five stages are:

1. Procurement and specification: Use data from similar equipment to select for reliability and maintainability.

2. Commissioning and early operation: Capture all related costs, make baseline measurements of performance for OEE calculations and tracking.

3. Maintenance and optimization: Preserve performance through effective planned, preventive and condition-based maintenance.

4. Life extension or refurbishment: As equipment nears its expected end-of-life (often signaled by rising maintenance needs), use maintenance history data to determine whether to upgrade, overhaul, rebuild or replace.

5. Decommissioning and replacement: Optimize timing of replacement using analytics, and use maintenance data to support selection of reliable, maintainable equipment.

Overcoming implementation challenges

While a fixed asset management program yields cost savings and increased operational efficiency, implementation is rarely straightforward. Specific challenges or barriers encountered depend on the systems in place at the outset. A business already engaged in tracking assets will face fewer issues than one with only a very basic asset register and no maintenance management systems. However, common problems include:

- Poor asset data accuracy: Locations and purchasing information are often incorrect or missing. When performing audits, ghost assets (equipment listed but not physically present) may be discovered.

- Cultural resistance or inconsistent participation: Persuading people to change established working practices is always difficult, especially when the benefits will take time to become clear.

- Underutilized CMMS features: This core element of fixed asset management software is often used only to raise work orders. However, most systems have capabilities that include retaining maintenance histories, MRO management and maintenance scheduling.

- Limited understanding of lifecycle costing: Cost management pressures can delay maintenance activities, even though these would avoid far larger future costs. Education about the benefits supports asset performance improvement efforts.

Efforts to overcome these barriers should focus on two areas: improving data accuracy (including standardizing naming conventions), and ensuring leadership alignment with program goals.

Evaluate fixed asset management strategy

In manufacturing businesses, fixed assets, especially plant and equipment, lie at the heart of revenue generation. However, profitability depends on effective and efficient use throughout their lifecycles.

Maintenance, preferably supported by a CMMS, handles actions to reduce unplanned downtime and extend life, but this only addresses part of fixed asset management. It also requires a well-maintained asset register, coupled with practices, disciplines and use of technology to ensure assets are tracked and managed throughout their lives.

Used in an integrated program, fixed asset management raises ROI through better uptime, lower repair costs and longer asset lives. In addition, new technologies enable a transition from old, reactive management approaches to predictive operations that prevent rather than respond to problems. Furthermore, strong fixed asset practices strengthen compliance (both regulatory and GAAP) and operational resilience.

In summary, fixed asset management maximizes the return the business gets from its investment. Ready to improve uptime and reduce total cost of ownership? Connect with ATS today to speak with an expert and explore solutions tailored to your operation.