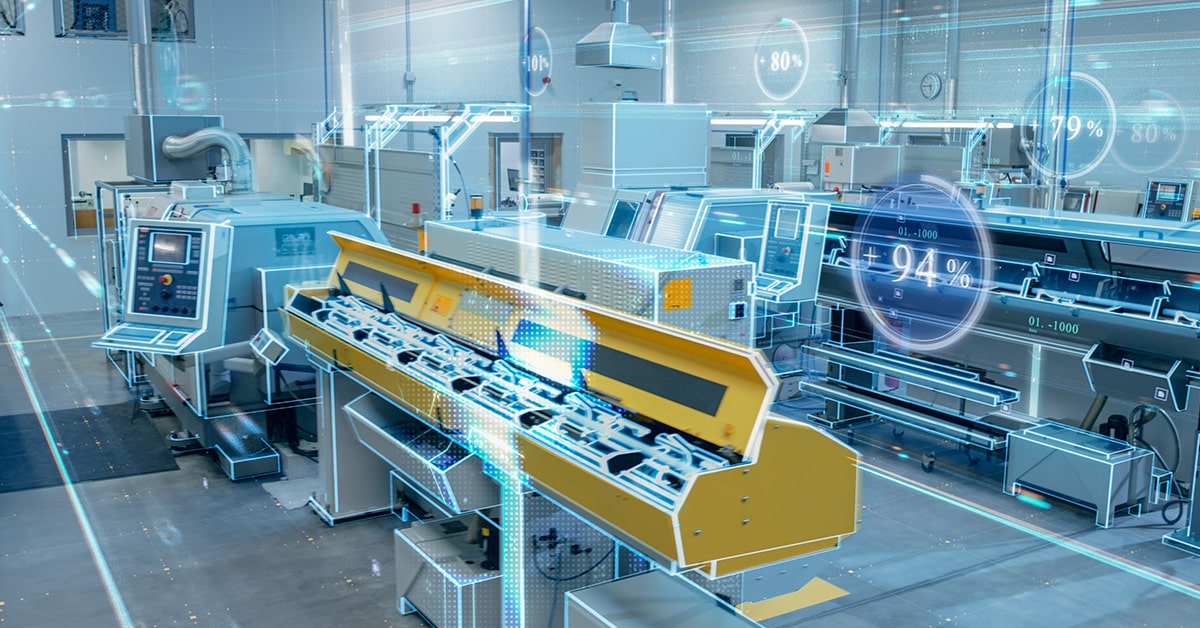

Modern manufacturing environments are more connected than ever. Not only are components and assemblies passed from machine to machine, but a considerable amount of information now passes between them at all times. Every point on a production line communicates with each other as well as with the operators, creating a connected network that enhances efficiency, improves maintenance procedures and guides better decision-making.

In smart factories, two core digital technologies—the Industrial Internet of Things (IIoT) and a Manufacturing Execution System (MES)—work together to enable data-driven manufacturing and real-time process control. While they may appear similar, each plays a unique role in driving digital transformation. Plant managers, engineers and operations leaders who want to harness the power of digitization within their facilities need to understand how these technologies serve their goals and interact with each other to deliver measurable benefits. What follows is a brief overview of each type of system, how they connect and what they can do for manufacturers.

What is IIoT?

The Industrial Internet of Things is a term used to describe the network of connected industrial devices and sensors that collect real-time data from equipment, processes and people. Its core function is to acquire information that can be utilized for predictive analytics, remote monitoring and machine-to-machine communication. With it, manufacturers can have greater visibility into the performance of their systems, enable predictive maintenance protocols and make decisions faster and with more accuracy.

What is MES?

On the other hand, an MES is a software package that manages, monitors and controls production processes on the shop floor. It serves a number of purposes, including production scheduling, work order management, quality control, traceability and performance monitoring. Among the many benefits an MES can deliver for manufacturers include enforcing standard operating procedures, reducing manual errors and improving overall efficiency. Manufacturers often use an MES to track batch production, generate compliance reporting and provide real-time production updates.

Key differences between IIoT and MES

The primary difference between IIoT platforms and MES solutions lies in their core functions: IIoT focuses on data collection and connectivity, while MES centers on process management and execution. Another way to look at it is that IIoT is concerned with capturing raw data from equipment and sharing it, whereas MES uses structured data to enforce production workflows.

Another key distinction is how each type of system is constructed. Because it is spread across numerous machines and sensors throughout the facility, IIoT is decentralized and often lives in the cloud. On the other hand, MES typically takes the form of a centralized, software-driven platform. Manufacturers can implement both within their operations and benefit because IIoT provides insights while MES gives them control and coordination.

IIoT | MES | |

Purpose | Collecting data and connecting assets | Managing production processes and executing workflows |

Scope | Decentralized and cloud-friendly | Centralized and software-based |

Data type | Raw data from machine sensors | Structured data from various sources |

Benefits | Greater visibility and faster decision-making | Streamlining SOPs and preventing human error |

How IIoT and MES work together

As complementary technologies, IIoT and MES can work together successfully in a manufacturing environment. MES relies on the data provided by IIoT sensors, which not only enhances the accuracy of what it does but also provides the kind of real-time responsiveness that can lead to significant process improvements. For example, an IIoT sensor can detect an anomaly in a particular machine. Based on that information, the MES can automatically adjust workflows and scheduling to avoid malfunction and minimize unplanned downtime. This allows maintenance teams to correct the anomaly while production continues unabated around the machine experiencing the failure.

Benefits of leveraging both technologies together

Among the many benefits of integration between IIoT and MES solutions include:

- Improved decision-making through richer data context

- Faster detection and resolution of quality issues

- Closed-loop feedback for continuous improvement

- Maximized ROI from technology investments

- Higher production efficiency and reduced downtime

- Real-time visibility across all layers of the factory

- Better compliance reporting and quality control

- Providing a foundation for advanced Industry 4.0 initiatives such as digital twins and autonomous manufacturing

Implementation considerations

To maximize the value of these systems, manufacturers should first evaluate their current operations, technology stack, and integration needs to ensure seamless IIoT and MES implementation. This begins with taking stock of their business goals, whether they want to reduce downtime, improve quality, increase throughput or some combination of improvements. Based on their findings, manufacturing leaders need to sit down and compare systems to make sure they offer the features and integrations that will deliver the highest ROI. They also should check to see if the platforms they choose will be capable of scaling to their needs in the future.

The earlier manufacturers can involve their IT, OT and leadership teams in this process, the better. This will ensure that all stakeholders understand these new systems and will be onboard with them from the start. This also ensures that questions concerning cybersecurity, data governance and change management will be addressed as soon as possible to remove any potential points of friction during the implementation process. Training initiatives also will be important for ensuring the highest levels of buy-in and adoption from employees.

Manufacturers who harness the capabilities of both IIoT and MES technologies put themselves in a better position to success now as well as into the future. Partnering with a leader in digital transformation like ATS means you can have access to the most effective strategies for implementing IIoT and MES systems into your operations. Get in touch with one of our experts today to explore your digital maturity and discuss potential strategies for integration.