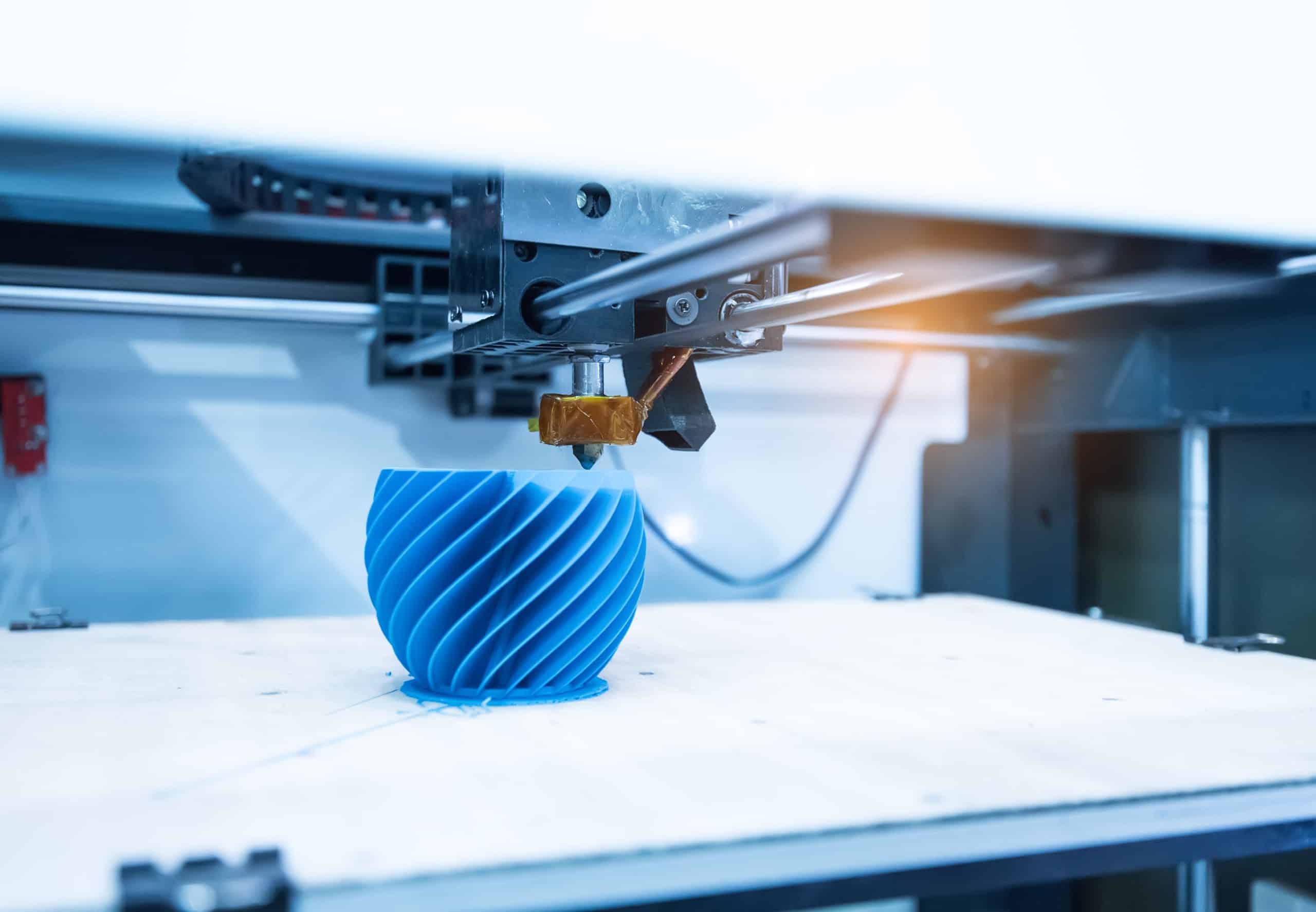

In a number of manufacturing scenarios, 3D-printed parts are already providing highly reliable alternatives to traditional replacement parts.

In the Star Trek television series, one of the many futuristic devices featured was the replicator, an appliance about the size of a microwave oven. It could produce anything on demand—from a dry martini to a bowl of chicken soup. But while that was from a fictional world hundreds of years into the future, nowadays 3D printers are the closest thing we have to a real-life replicator.

These devices are already transforming processes such as rapid prototyping, where new iterations of parts or products can be printed within hours of tooling. In some cases, additive manufacturing is being integrated directly into production lines to create specific components on-demand. The impact of 3D printing on manufacturing MRO operations and asset management can be tremendous, saving the manufacturing industry significant amounts of time and money while boosting uptime.

The prospects of 3D printed parts

Star Trek foreshadowed a future that is now here. In that universe, the replicator didn’t just serve dinner—it was also used to make spare parts for the ship, so it wouldn’t have to return to base every time a repair was needed. In a similar way, manufacturing plants can use 3D printing to create quality 3D-printed industrial parts for just about any type of equipment in any environment, solving spare parts issues quickly and economically. 3D printing capabilities can be especially important for manufacturers who need difficult-to-find parts and accessories for aging machinery, especially at legacy manufacturing plants.

Many 3D-printed parts outlast alternatives created using more conventional methods, even in rough industrial environments. For example, using a 3D printer, experts can create plastic parts that are enhanced with metals to improve durability under challenging conditions. And as time goes on, 3D printing technology keeps getting more advanced through AI, allowing for more enhancement possibilities and even more 3D printing industrial applications. However, not all parts may be suitable for the 3D printing process, so it’s important to complete qualification and testing before integrating printed components into a build.

Common 3D printing applications in manufacturing operations

As the use of 3D printing in manufacturing becomes more effective and robust, manufacturers are finding new ways to integrate it into their processes. Currently, it’s not uncommon to find 3D printing being used to produce:

- Spare and replacement parts

- Fixtures, jigs and tooling

- Guards, covers and housings

- Custom brackets and adapters

- Temporary parts for emergency repairs

Materials used in industrial 3D printing

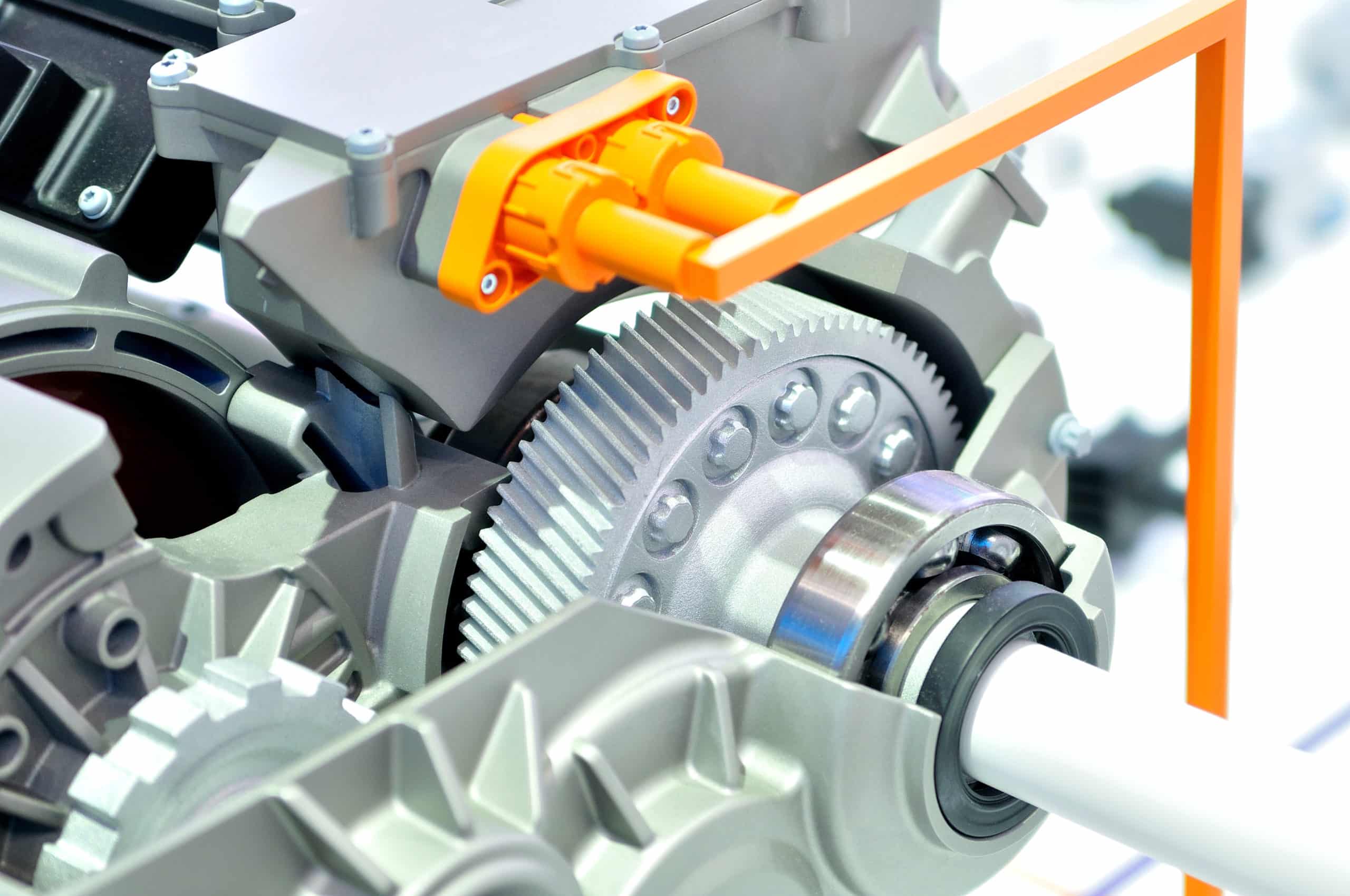

Consumer-grade 3D printers typically use PLA filament to create simple plastic models. Industrial additive manufacturing, however, requires more durable materials. Fortunately, the technology has advanced to encompass a wide range of materials including reinforced polymers, metal-filled composites and even full-metal powders using laser sintering techniques. Each of these presents its own unique profile in terms of strength, heat resistance and speed of printing, so it’s critical to know when each one makes the most sense.

When 3D printing makes sense—and when it doesn’t

Although 3D printing techniques have advanced rapidly and offer unique advantages, 3D printing for manufacturing delivers the most value in specific situations. In fact, there are several scenarios where it truly does make sense, including:

- Low-volume parts

- Long-lead-time components

- Emergency replacement parts

- Obsolete equipment components

On the other hand, there are other situations in which 3D printing would be a poor fit, such as:

- High-volume production

- Parts with complex shapes featuring extremely tight tolerances without post-processing

- Regulatory-restricted components

Impact on repairable parts management

The 3D printing effect on manufacturing and maintenance has been significant and only continues to grow. While some manufacturers already use 3D printing to create prototypes, industrial operations are increasingly finding that 3D printing applications for efficient spare parts management is essential.

For example, if a company needs a handful of replacement parts but finds that they can only purchase each needed product in bulk, using a 3D printer to create just a small batch can be more cost-effective. One of the other uses of 3D printing in manufacturing is for obsolete parts. It’s not unusual for machine lifecycles to greatly exceed the number of years the equipment manufacturer makes spare parts for it.

A factory might have a 15-year-old machine that the original equipment manufacturer stopped making spare parts for after 10 years. In that scenario, 3D parts manufacturing with a 3D printer can be a lifesaver. 3D printing may still sound futuristic, but it’s already playing a role in manufacturing operations today, producing parts that fold seamlessly into supply chains worldwide.

ATS brings deep expertise in 3D printing to support MRO organizations strengthen reliability and improve outcomes. Our team applies proven knowledge and innovative thinking to ensure they can leverage additive manufacturing with speed, consistency and the confidence that every decision is backed by expert support. To learn more about 3D printing applications in manufacturing and the ways 3D printing can help your legacy machines, contact us.