Maintenance technology is a key area of innovation in manufacturing — today and for the foreseeable future. With efficiency, speed and reliability playing a more important role than ever in the success of manufacturing businesses, it’s critical to remain current with advances in maintenance technology to keep pace with competitors and deliver the experience that customers expect.

Smart factories driven by Industry 4.0 technology are already becoming pervasive throughout the manufacturing landscape. According to Travancore Analytics, over 70% of the top 200 manufacturing companies globally are exploring augmented reality and virtual reality in industrial automation to enhance their operations.

The success and efficiency of these factories proves that advanced technology is necessary to remain viable and competitive in the manufacturing industry today; the efficiencies that these technologies provide are improving not only maintenance challenges, but the entire productivity of the plant and enterprise.

Read on to learn more about the benefits of augmented reality, virtual reality and mixed reality in maintenance.

What is immersive technology in manufacturing?

Immersive reality technology in manufacturing includes augmented, virtual and mixed reality technology and the ways in which they enable more effective and efficient maintenance practices. These technologies offer ways to obtain more information at the right time, while also facilitating access to tools and scenarios that would not otherwise be possible.

Immersive technology supports maintenance by offering real-time data, visual overlays, remote guidance, and simulation capabilities. It plays a key role in the smart factory strategy and integrates tightly with the Industrial Internet of Things (IIoT), enabling seamless connections between physical machinery and digital systems.

AR, VR and MR each support different but overlapping needs across the manufacturing process:

- AR technology enhances real-world environments with overlays

- VR technology simulates new environments for immersive training and planning

- MR blends the two to facilitate real-time interaction and collaboration

Together, these immersive tools are redefining how the manufacturing industry approaches maintenance, paving the way for smarter, more connected operations built on the foundation of AR and VR in manufacturing.

Augmented reality (AR)

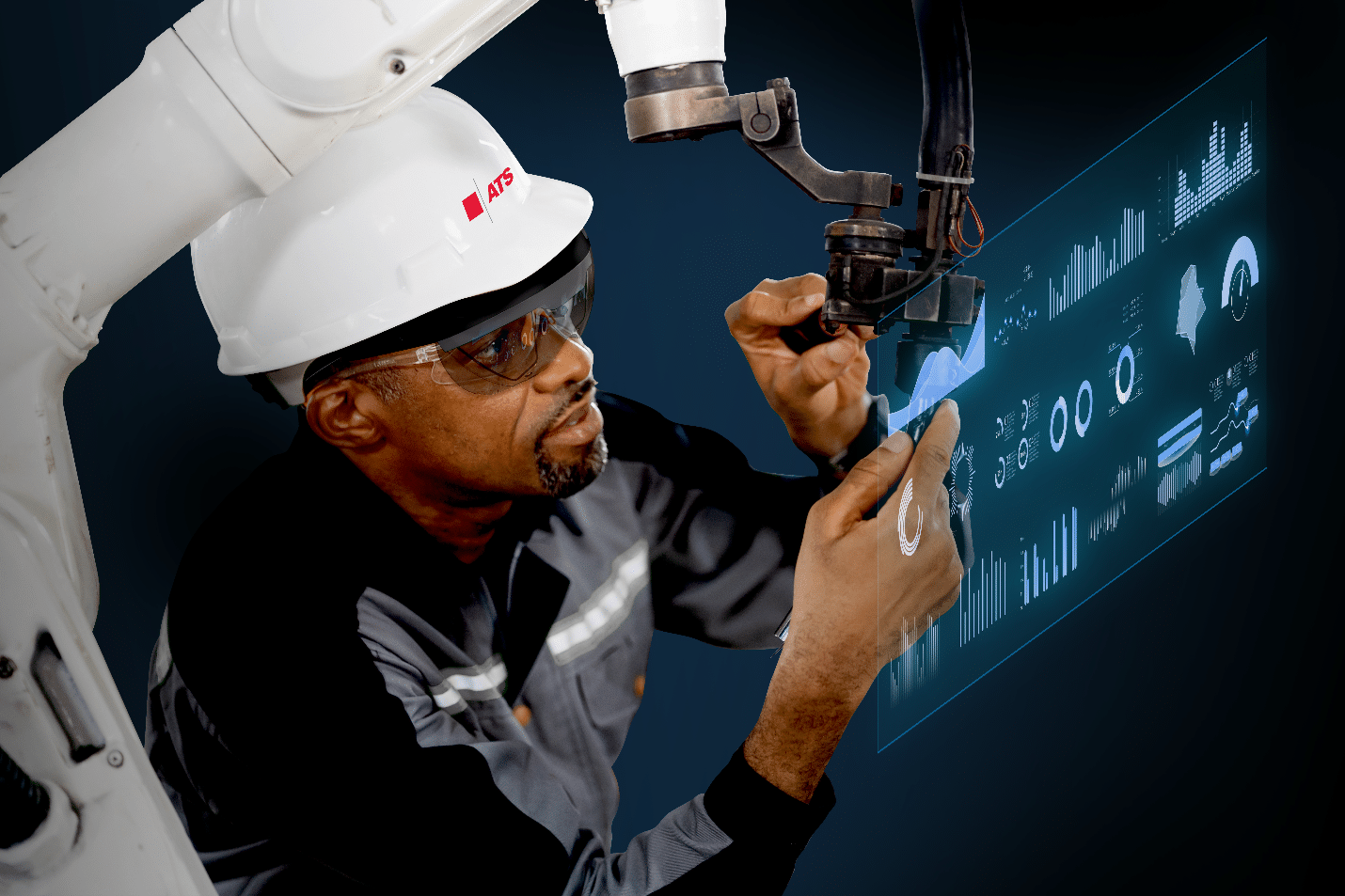

Augmented reality is technology that adds information to the existing real-world environment in which a technician is present. Augmented reality is enabled through tools such as connected goggles or glasses. In most cases, AR will overlay details about what the technician is viewing.

AR draws information from data sources to provide a “heads-up” view of the manufacturing environment, helping the technician make fast, accurate decisions using the full scope of information at hand. The technician can use hand gestures and other methods to interact with the information.

The key differentiator of augmented reality is that it focuses exclusively on the environment in which the technician is located — including the machines, processes, products and people — and adds (or augments) information to facilitate more effective operations.

Virtual reality (VR)

Virtual reality presents a view of an environment different from that in which the technician or viewer is located — and can even present an environment that does not exist at all. Virtual reality is typically facilitated through a headset and enables full interaction with the virtual environment being presented.

VR helps simulate real-world environments safely, allowing employees to train on dangerous equipment or rare failure scenarios without risk. These simulations increase learning retention and support safety-focused culture building.

Virtual reality is used for:

- The vetting and inspection of processes remotely

- Interaction with large, heavy or unbuilt parts

- Planning floor layouts and facility redesigns

- Designing parts and components

- VR training and upskilling of technicians

- VR-based certification for safety protocols

- Digital twin simulations for complex troubleshooting

- Pre-installation training for line upgrades

Mixed reality (MR)

Mixed reality combines elements of augmented reality and virtual reality. A mixed reality implementation leans toward one technology while incorporating elements of both. In MR, the technician might see and interact with their environment and virtual enhancements simultaneously.

A powerful use case: An on-site technician wearing MR glasses collaborates in real time with an off-site subject matter expert. Both parties can view and interact with the same machine virtually, resolving complex issues faster.

Additional advantages of MR include:

- Hybrid use cases enabling cross-facility collaboration

- Live data updates in mixed reality work instructions

- Improved diagnostics through contextual overlays

- Enhanced training and real-time support from remote experts

Immersive technology benefits and uses in maintenance

Immersive technology — including augmented reality, virtual reality and mixed reality — offers several advantages in maintenance practices throughout the manufacturing field. These tools enhance operational efficiency by streamlining workflows, reducing downtime, and empowering every worker with faster access to actionable information.

Throughout this section, we’ll explore the strengths and uses of each type of technology for maintenance technicians and other personnel.

Benefits & uses of augmented reality in maintenance

Impactful AR solutions for industrial maintenance are providing real-time digital overlays on physical assets, enabling technicians and engineers to complete tasks more accurately, efficiently and safely. From quality control to hands-free inspections and remote support, AR is transforming the way every worker interacts with equipment on the shop floor while supporting core principles of industrial maintenance safety.

AR in maintenance brings numerous benefits:

- Generally unobtrusive, hands-free technology such as goggles or glasses

- A lower barrier to entry, since the tools overlay information on the existing environment

- Real-time, easy access to machine data, troubleshooting and training

- Quick access to historical maintenance data

- Transmits institutional knowledge from experienced to new technicians

- Real-time, interactive technician training

- Makes unfamiliar maintenance tasks more accessible

- Integration with CMMS and digital twins

AR applications in maintenance include:

- Real-time, at-a-glance performance data via heads-up displays

- Information about personnel availability, specialization, and training

- Step-by-step instructions for repairs

- Fast decision-making for proactive maintenance

- Enhanced training environments

- AR-based inspections with automatic documentation

- Remote expert support for live guidance (e.g., SME directs a technician’s actions

Benefits & uses of virtual reality in maintenance

Virtual reality is reshaping how manufacturers approach employee training, equipment planning, and safety preparedness. By creating immersive, risk-free environments, VR training modules allow personnel to interact with a 3D model of machinery as if it were real. This not only accelerates learning but also improves decision-making and reduces human error during complex maintenance tasks across the production process.

Benefits of VR in maintenance include:

- Virtual access to machinery with full interaction

- Reduced costs for travel and on-site work

- Ability to interact with unbuilt products

- Enhanced communication with customers and remote teams

- Risk-free training environments

The top VR maintenance use cases:

- Remote vetting and process inspection

- Interactions with large or unbuilt parts

- Facility planning and production layout reviews

- New employee onboarding

- VR-based certification and safety training

- Digital twin simulations for troubleshooting

- Pre-installation preparation for new systems or upgrades

Benefits & uses of mixed reality in maintenance

As a hybrid of both AR and VR, mixed reality bridges the gap between physical and digital environments, making it a powerful tool for enhancing operational efficiency and cross-functional collaboration. Whether used for product design refinement, live diagnostics, or team-based maintenance, AR VR technology delivered through MR empowers manufacturers to work smarter, faster and more collaboratively across locations.

MR’s hybrid strengths offer:

- On-site and virtual interactivity simultaneously

- Access to a broader pool of expert resources

- Real-time collaboration across global teams

- Reduced downtime through faster resolution

- Enhanced training and efficiency

- Cross-facility collaboration for troubleshooting high-value equipment

The most valuable MR use cases include:

- Remote collaboration between on-site and off-site teams

- Step-by-step maintenance training with visual assistance

- Real-time updates to MR work instructions based on sensor data

- More accurate work tracking

- Better personnel guidance during complex operations

How AR, VR and MR fit into a predictive maintenance strategy

AR, VR and MR all play a powerful part in advancing predictive maintenance (PdM) in manufacturing. By aligning immersive technologies with data-driven maintenance strategies, manufacturers can unlock new levels of precision across the production process and accelerate product development cycles through smarter, faster decision-making.

- AR overlays visualize sensor data directly on machines, enabling real-time diagnostics.

- VR simulations let teams rehearse fault scenarios using digital twins before actual issues arise.

- MR tools allow maintenance teams to collaborate remotely to resolve issues faster and reduce MTTR (mean time to repair).

- When combined with predictive maintenance solutions, immersive technology strengthens root cause analysis and forecasting.

For example, an AR interface connected to a CMMS might show current vibration or temperature data next to a compressor unit, while a technician uses MR to discuss findings with a remote engineer. VR enables them to train on a simulated failure event, improving response times.

ATS’s Reliability 360® platform can evolve alongside immersive technologies to bring diagnostics, simulation, and performance analytics into a single intuitive experience.

AR, VR and the future of maintenance

ATS is focused on providing the latest maintenance technology and best practices for manufacturers through predictive maintenance, technician expertise, best-in-class standards and processes, to help you keep your factories running. We specialize in increasing uptime, improving asset reliability and reducing manufacturing costs.

Looking ahead, AR, VR and MR will likely be used in conjunction with artificial intelligence, machine learning and 5G to enhance real-time support, automation and decision-making. The convergence of these technologies is set to transform the manufacturing sector for years to come.

To learn more about augmented reality in manufacturing and other technology — and how we can help you drive innovation in your operations — contact us today.

References

Travancore Analytics. (2024, March 28). The rising role of AR VR in industrial automation. Travancore Analytics. https://www.travancoreanalytics.com/en-us/ar-vr-in-industrial-automation/

PwC. (2020). Seeing is believing: How virtual reality and augmented reality are transforming business and the economy. https://www.pwc.com/gx/en/technology/publications/assets/how-virtual-reality-and-augmented-reality.pdf

Porter, M. E., & Heppelmann, J. E. (2017, November). Why every organization needs an augmented reality strategy. Harvard Business Review. https://hbr.org/2017/11/why-every-organization-needs-an-augmented-reality-strategy

Precedence Research. (2025, January 17). Augmented reality (AR) and virtual reality (VR) in manufacturing market. https://www.precedenceresearch.com/augmented-reality-and-virtual-reality-in-manufacturing-market

Whitley, E. (2023, September 6). Tips for using AR/VR for training manufacturing workers. Training Industry. https://trainingindustry.com/articles/workforce-development/tips-for-using-ar-vr-for-training-manufacturing-workers/

Gravity Jack. (n.d.). The benefits of AR and VR training in manufacturing. https://www.gravityjack.com/training/manufacturing-industrial/the-benefits-of-ar-and-vr-training-in-manufacturing/

IIoT World. (2025, February 28). Leveraging augmented reality (AR) and virtual reality (VR) for remote maintenance in industrial IoT. https://www.iiot-world.com/augmented-reality/augmented-reality-remote-maintenance/

Whitley, E. (n.d.). 4 clever tips to use AR and VR for optimizing maintenance. Reliable Plant. https://www.reliableplant.com/Read/32551/4-clever-tips-to-use-ar-and-vr-for-optimizing-maintenance

LightGuide Systems. (2022, February 23). 6 uses of augmented reality for manufacturing in every industry. https://www.lightguidesys.com/resource-center/blog/6-uses-of-augmented-reality-for-manufacturing-in-every-industry