All-in-one condition monitoring

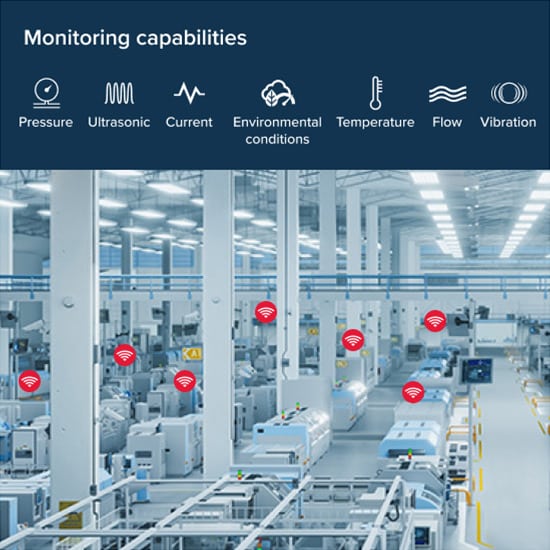

Our all-inclusive R360® Machine Health Monitoring uses the latest sensor technology to monitor vibration, temperature, current, pressure, humidity and more. It is driven by our team of condition monitoring experts who analyze machine data and provide actionable steps to boost productivity, reduce costs, and drive uptime—ROI guaranteed.

See it in action—here’s what the live demo includes:

- Explore real-time alerts, dashboards and analytics tools

- Discover our data-driven, holistic approach to operations & reliability

- See how our solution drives ROI and measurable gains

Schedule a demo

Proven expertise, guaranteed results

Cost savings resulting from Reliability 360® Machine Health Monitoring isn’t just a promise, it’s a guarantee.

Guaranteed minimum

3X ROI

We are confident in our ability to provide cost savings for your organisation; we guarantee it.

Rapid adoption

50%

50% of customers choose to expand their sensor coverage within 4 months of seeing initial value.

Sensors available

20+

With a growing portfolio built to enhance reliability and meet evolving customer needs.

Key features designed for success

Comprehensive equipment monitoring

Monitor critical assets 24/7 with 22+ sensor types, feeding real-time data to the dashboard.

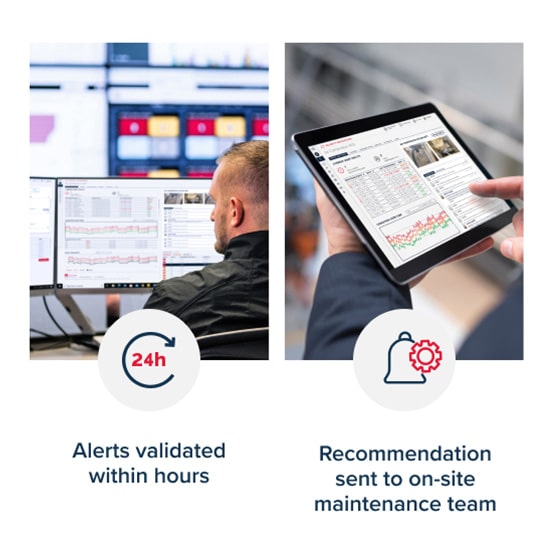

Expert data analysis

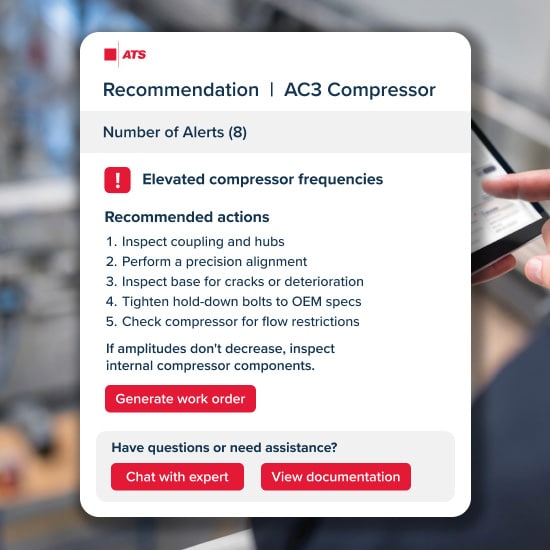

Condition monitoring experts analyze every alert and send detailed recommendations to the on-site maintenance team.

Detailed recommendations, streamlined workflow

Recommendations and alert data are sent to the dashboard or your CMMS, where maintenance teams can consult ATS experts using built-in tools before heading to the floor.

Single source for maintenance and reliability

Rely on our expert maintenance and part repair support if needed to quickly address potential failures and aid your on-site team.

Ongoing managed service

Each customer is supported by a condition monitoring expert and dedicated success team, with ongoing engagement focused on daily operations and long-term value beyond go-live.

Unplanned downtime holding up production?

With our machine health monitoring solution, the ability to identify potential failures has become a reality for one of our valued customers. Witness how our proactive approach enhanced their manufacturing process, ensuring maximum efficiency and reduced unplanned downtime.

“I can’t say enough good things about ATS. I’m in daily communications with their reliability team and they answer all my questions and provide suggestions that improve my operational efficiency.”– Reliability manager, leading cpg manufacturer